Views: 35 Author: Site Editor Publish Time: 2022-11-26 Origin: Site

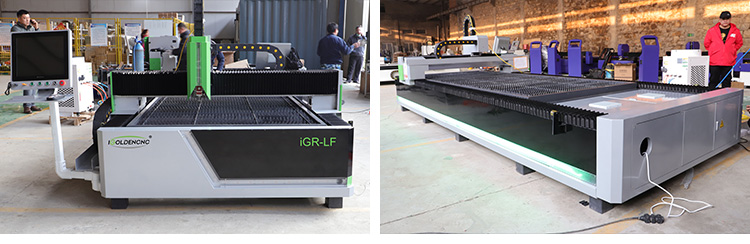

Sheet Metal Cutting Machine - Stainless Steel Cutting Machine,High Power Stainless Steel Cutting Machine, High Speed Cutting And High Power Laser Source. We Design And Supply Fiber Laser Cutting Machine And Tube Laser Cutting Machine, Get Quote。

Stainless Steel Sheet and Metal Tube Laser Cutting Machine

Stainless steel sheet and metal tube laser cutting machine is mainly used in both sheet metal and metal tubes cutting. It can cut maximum stainless sheet with 3000mm×1500mm size, the maximum tubes size with length 6000mm, round pipe Ф25-Ф160mm, square pipe 25mmx25mm-100mmx100mm (diagonal 30mm-160mm). The machine is especially suitable for cutting metal sheet or and metal tubes. The materials' supporting device can keep stable cutting for long time work.

Select Sheet Metal Laser Cutting Machines, first you need to confirm the thickness and size of the cutting plate or pipe, Igolden laser has 1000w fiber laser cutting machine, 1.5 kw fiber laser cutting machine, 2000w laser cutting machine, 3kw fiber laser cutting machine, 4kw laser cutter,15000 watt fiber laser cutting machine, 30000w power Laser Cutting Machines to choose, Work surface can be customized according to your needs. After confirming good equipment, you can go to peers or the market to understand equipment performance and equipment parameters, select good performance laser cutting machine company, service number of manufacturers to communicate in the early stage, and to the factory on-site sampling, later can be the configuration of equipment, prices, services and so on have a detailed understanding. The core parts of the cutting machine, such as lasers, cutting heads, water tanks, etc., should be especially careful when choosing, because the quality of these parts can directly affect the quality of the cutting.

Sheet Metal Fiber Laser Cutting Machine

1. The precision of the stainless-steel laser cutting machine is very high, and it can be applied to different products and different industries, such as kitchenware, trolleys, mechanical equipment (Mechanics), hardware, diagnosis and treatment and other manufacturing industries, especially in some Manufacturing industries with relatively high technical standards have particularly high requirements for laser cutting machines. It can carry out detailed cutting and drawing of different products, and then make excellent products.

2. The cutting data information of the stainless-steel laser cutting machine is rapid. The cutting speed of the traditional cutting machine is relatively slow, which will waste a lot of working time. The current standard laser cutting machine can avoid this problem very well, and even its speed is 100 times that of the traditional cutting machine.

3. The stainless-steel laser cutting machine is very cost-effective. Compared with the same industry (product), the laser cutting machine (main use: metal material cutting, non-metal material cutting) has advantages (expression: can run over the beneficial situation of the other party), and even only 60% of the same industry. It is the key reason why many manufacturers choose laser cutting machines.

4. The application of stainless steel (stainless acid resistant steel) laser cutting machine (main purpose: cutting of metal materials, cutting of non-metal materials) is low-cost. For the company, the operation of the company's cost is very important. If there is no strict control on product costs, the company will increase product costs and reduce profitability. According to the data display information, the production price of the current standard laser cutting machine can only be around 3 dollars per hour, while the cost of the traditional cutting machine or the same industry can reach 30 dollars an hour. The difference between this is very important.

5. The maintenance cost of the stainless-steel laser cutting machine in the middle and later stages, and the maintenance cost is low. The laser cutting machine is not easily destroyed, and the product is durable. It should be understood that the maintenance of mechanical equipment products is very expensive, and the Prey laser stainless steel laser cutting machine has great advantages in these aspects.

Fiber laser cutting machine is a laser cutting machine using a fiber laser generator as a light source. CNC sheet cutting machine is a newly developed new fiber laser output high energy density laser beam, and is gathered on the surface of the workpiece, melting and gasifying the area that is irradiated by ultrafine focus spectrum, and moving spot illumination through a CNC mechanical system Automatic cutting, fast speed, high precision.

Stainless steel is a group of iron-based alloys that contain a minimum of approximately 11% chromium. Stainless steel pipe components are widely used in sanitary fittings, kitchenware, appliance brackets, surgical instruments, food manufacturing, and other industries. Thanks to high precision, high speed, and diversified functions, more and more manufacturers choose the automatic stainless steel circle cutting machine and tube laser cutting machine. As one of the leading stainless steel laser cutting machine manufacturers in China, IGolden laser provides the best quality CNC stainless steel pipe cutting machine/cutter at a competitive price. As one of the professional stainless steel laser cutting machine manufacturers, our company manufactures the machines, for example, small CNC steel laser cutter, whic can provide good stainless steel laser cutting services to meet the requirements of the production.

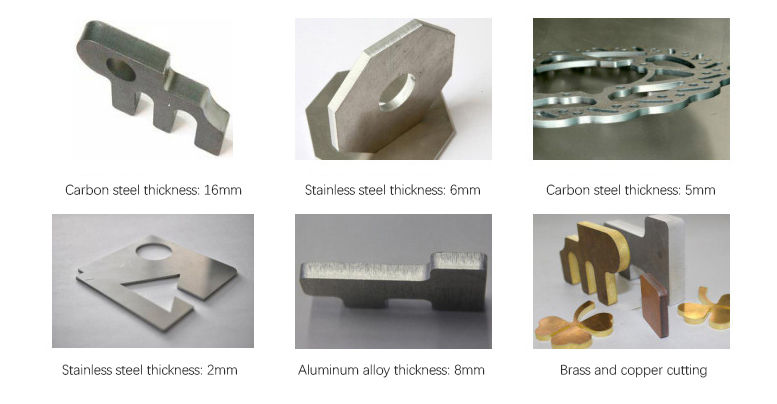

Fiber laser cutting machines can cut all kinds of metal materials such as:

Iron、Alloy、Brass、Copper、Titanium、Aluminum、Carbon steel、Structural steel、Stainless steel

A fiber laser cutting machine for metal is a laser machine that emits light from a laser and focuses it into a high power density laser beam via an optical path system. The laser beam hits the surface of the workpiece, causing the workpiece to reach its melting point or boiling point, while the high-pressure gas coaxial with the beam blows the molten or vaporized metal away. With the movement of the relative position of the beam and the workpiece, the material is finally cut to achieve the purpose of cutting. The laser cutting process replaces the traditional mechanical knives with invisible beams. It has high precision, fast cutting speed, is not limited to cutting pattern restrictions, and saves material by automatic typesetting, has a smooth incision, and has low processing costs. It will gradually improve or replace traditional metal cutting process equipment. The mechanical part of the laser cutter head has no contact with the workpiece. It will not scratch the workpiece surface during work. The laser cutting speed is fast and the incision is smooth and flat. Generally no subsequent processing is required. The heat affected zone is small, the plate deformation is small, and the slit is narrow ( 0.1mm~0.3mm); No mechanical stress, no cutting burrs on the notch; High precision machining, good repeatability, no damage to the surface of the material; NC programming, can process any plan, can cut the whole board with a large format, without open mold, economical and time-saving.

Fiber laser cutting machine applications are very extensive, include many industries, and it is one of the necessary equipment for many businesses.

Advertising industry

Sheet metal processing industry

Chassis cabinet production

Spring sheet production

Subway parts

Elevator manufacturing

Kitchen kitchenware manufacturing

Fiber laser cutting machine is widely applied in sheet metal processing, advertising sign making, high and low voltage electrical cabinet making, mechanical parts, kitchen utensils, automobiles, machinery, metal crafts, saw blades, electrical parts, eyewear industry, spring sheet, circuit board, electric kettle, medical micro Electronics, hardware, knife measuring tools and other industries.

content is empty!