Views: 19 Author: Site Editor Publish Time: 2021-11-04 Origin: Site

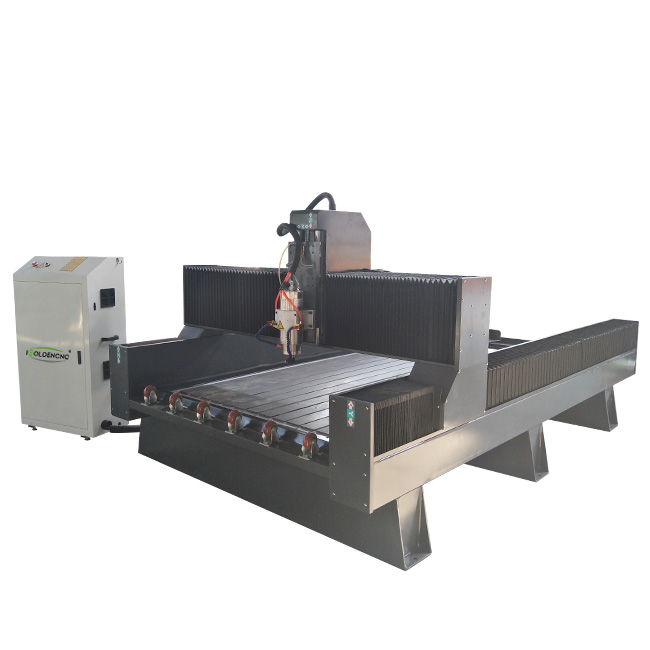

Tombstone engraving machine has two 5.5KW water cooling spindles, it’s heavy duty type and this type engraving machine can engrave two stone plate at one time, it’s synchronous for dual work station. The whole tombstone machine use Taiwan square rail transmission and helical rack and pinion transmission. Steel water tank for recycling and dust proof for three axis to ensure the machine’s life. There are kinds of stone materials can be used for tombstone, such as Fieldstones, Granite, Marble and limestone, sandstone, you can use the CAM software to do the design and use our machine for carving and processing.

1. Heavy duty with thick seamless steel lath body structure. By strict vibration aging technology to remove the internal stress , dust-free sandblasting paint process, long-term use without deformation.

2. Three axis adopt Taiwan ABBA high precision linear guide rail, X and Y axis adopt rack and pinion transmission, fast working, high efficiency . Z axis adopts Germany and Taiwan ball screw,with high precision and long life time

3. Well compatibility: CAD/CAM designing software e.g. Type 3/ Artcam/ Castmate/ Wentai etc.

4. Can be used for marble ,granite or stone engraving work, also can do any kind of wood, PVC carving and cutting work.

5. Heavy bistratal Side plates, which can keep large supporting power for the gantry’s moving perfectly.

6. Independently Electric Control Box, with perfect wiring and free moving pulleys.

tombstone engraving machine application:

Mainly used for natural marble, granite, artificial stone, tombstone, milestone, tile, glass, bluestone,sandstone, crystal, microlite,mural, village tablet inscription, decoration skirting line,...such relief engraving, singlet line, character, flat pattern engraving, with rotary axis, can for stone cylinder,breast board, handrail, dragon columns,figure of Buddha...engraving.

Tombstone engraving machine maintenance:

1.Continuous running time under 10 hours a day, to ensure the normal work of the cooling water cleanand

the water pump, must not water shortage phenomenon in a spindle motor, regular replacement of cooling

water, in order to prevent the water temperature is too high. If working environment temperature is too low

in winter can replace the water inside cistern with antifreeze.

2.Each machine after use, should pay attention to clean up, be sure to clean up the dust on the platform and

the transmission system, on a regular basis (weekly) for transmission system (X, Y and Z axis) lubricating.

(note: X, Y, Z three axis polished rod with oil for maintenance; screw part with high-speed butter; winter if

working environment temperature is too low screw,polished rod guide or circular guide (squares) part should

use gasoline to wash clean first, then add oil, otherwise it will cause machine transmission part of the

resistance is too large and cause dislocation.

3.Maintenance checks to the appliance is, must cut off power supply, to monitor display and main circuit

power light goes out after may.

Scope of Application