Views: 33 Author: Site Editor Publish Time: 2021-09-02 Origin: Site

3D robot fiber laser welding machine,the arm length can reach to 1800mm * 3200mm. It is the preferred model in the metal material welding and processing industry.The machine can weld all kinds of metal. Off-line programming software and weld seam tracking system can be selected according to customer requirements, greatly improving work efficiency.

1. Higher processing efficiency: compared with argon arc welding, the efficiency is increased by more than 50%;

2. Better processing quality: the welding seam is smooth and even, and the protrusion is very small, without the need for polishing after welding;

3. Easier operation: The handheld head adopts ergonomic design, which is convenient to hold, light and easy to operate;

4. Abundant processing methods: pulse spot welding, continuous welding, quasi-continuous welding, etc. can be used according to processing needs;

5. Very low usage cost: ultra-high elector-optical conversion efficiency, saving a lot of electricity expenses for enterprises;

6. The equipment adopts integrated design, compact and beautiful structure, excellent beam quality, maintenance free, photoelectric conversion efficiency is more than 25%, and the service life of pump source is more than 100000 hours.

Shandong iGolden CNC Technology Co.,Ltd

Machine Parameters

Model | iGWL-RW- 1500 | iGWL-RW- 2000 | iGWL-RW- 3000 | |

Laser power | 1500W | 2000W | 3000W | |

Laser wavelength | 1080±10nm | |||

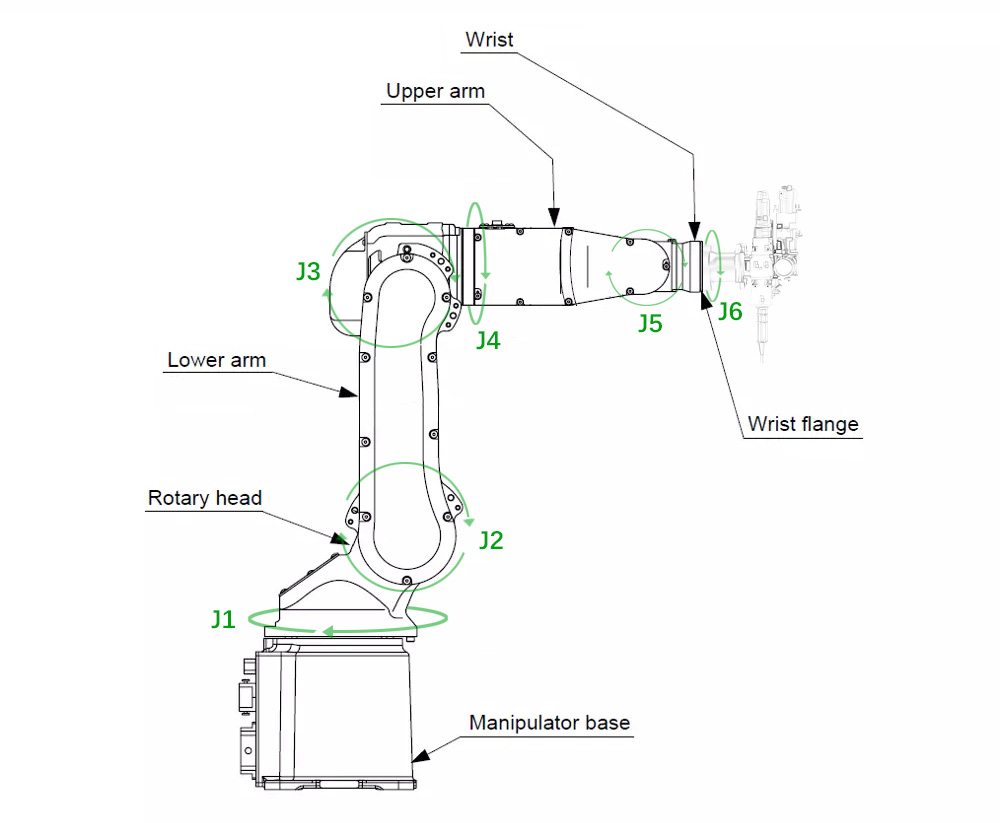

Robot | FANUC--Six-axis welding robot | |||

Maximum load on wrist | 12KG | |||

Repositioning accuracy | ±0.03mm | |||

Range of motion |

Lower arm | J1 | 340º/370º | |

J2 | 235º | |||

J3 | 455º | |||

Upper arm | J4 | 380º | ||

J5 | 380º | |||

J6 | 900º | |||

Max speed |

Lower arm | J1 | 260º/s | |

J2 | 240º/s | |||

J3 | 260º/s | |||

Upper arm | J4 | 430º/s | ||

J5 | 450º/s | |||

J6 | 720º/s | |||

Thickness of welding material | ≤4mm | ≤6mm | ≤8mm | |

Welding gap requirements | ≤0.3mm | |||

Voltage | 380V±10% | |||

Total power | ≤8kw | ≤10kw | ≤12kw | |

Gross weight | 200KG | |||

Remarks: Can be customized according to customer requirements | ||||

Advantages of Laser Welding Machine with Robot

1.High efficient

2.Widely application for different type of work piece

3.Compact design

4.Flexible laser beam mounting

5.LED operation panel

6.User-friendly operation interface

7.Laser cavity with modern laser technology

8.Without alignment after changing the flash lamp

9.External chiller and inner cooling unit

10.Long-operation working time

11.OEM deign is available for mass purchasing

12.Various optional accessories for multi-function and special parts

Laser Welding Machine with Robot Application Industries:

Machine shell sheet metal welding,Motorcycle,Automobile,Kitchen cabinets,staircase elevator,Food Machinery,shelf, oven,stainless steel door,window guardrail,distribution box,medical equipment,communications equipment,craft gifts,household and other industries.

Laser Welding Machine with Robot Application Materials:

Stainless steel, copper, aluminum, gold, chromium, silver, titanium, nickel and other metals or alloys, it can also be used for a variety of welding between different materials.