Views: 18 Author: Site Editor Publish Time: 2021-09-07 Origin: Site

This Stone CNC Machine can change tools automatically in the engraving process and keep good machining stability at the same time. With the Changsheng water cooling spindle, Japan Yaskawa servo motor and driver, Taiwan Syntec control system and auto lubrication system, the machine can achieve high efficiency and precision.

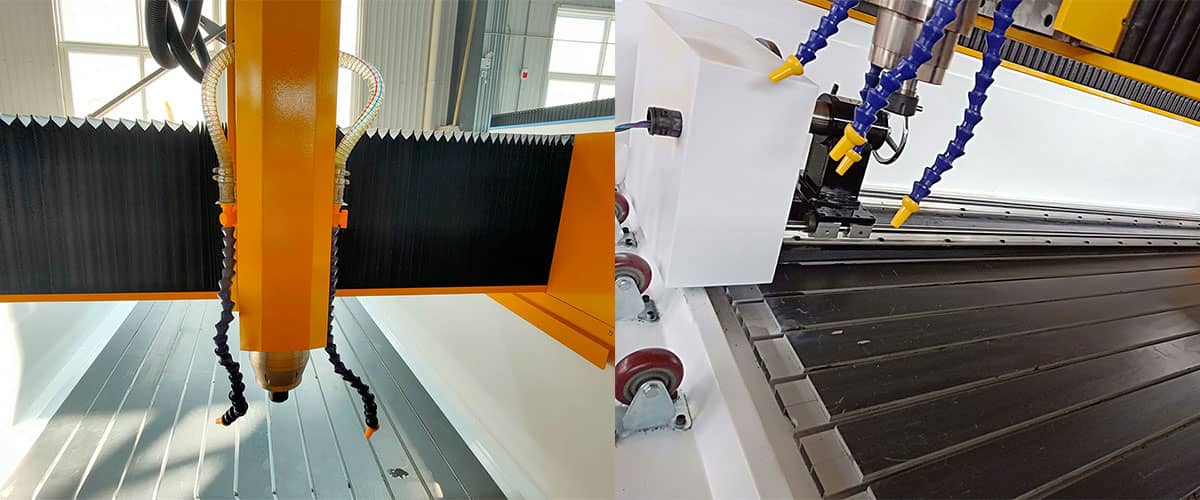

1. Using high-precision linear guide rail, X Y adopts high-precision helical gear transmission, which has large bearing capacity,stable operation, high precision, long service life and accurate lower cutter.

2. The whole Stone CNC Machine adopts steel structure for seamless welding, good rigidity, strong strength and rigidity, and the machine bearing capacity can reach more than one ton.

3. Software compatibility, compatible with a variety of CAD / CAM design software such as Typ3 / Artcam / Castmate / Wentai.

4. It has the functions of power failure recovery, breakpoint continuous carving and so on.

5. Thickened strong welding frame structure, fine grinding by milling machine to ensure installation accuracy.

Marble, granite, Chaina black, bluestone, jade, ceramics, crystal, glass, plastics, chemical synthesis in organic glass, PVC board, bamboo, aluminum composite panel, metal, plastic and other meterials for line carve, 2D carving, 3D sharp bottom sulpture, 3D relief, cutting, chamfering of edge, cutting and drilling process.

Suitable for stone, tombstone processing, advertising, decoration, arts and crafts industry etc..

How deep is the Stone CNC Carving Machine to engrave the stone? When I bought it, the carving was good. Why are there sculptures of different depths now? It's completely different from when I bought it. Did I buy a fake one?

The table tops used in the production of CNC engraving machine are all flat rolling mills, and there will be no unevenness of the table in mechanical control processing. But the materials we use for processing must have some unevenness. When we use the cutter head to face the material, it may just be the concave or convex point of the material. When we carve, there will be different carving depths.

It is also possible that the data size may be wrong, and different depths are being carved. When the depth of the engraving material is different, the five-point tool setting, the four corners and the center need to be performed before engraving. If the height of the material is too different, the material should be divided into three parts: upper, middle and lower parts. When carving, try to make the material flat. In this way, when carving, there will be no difference in depth.

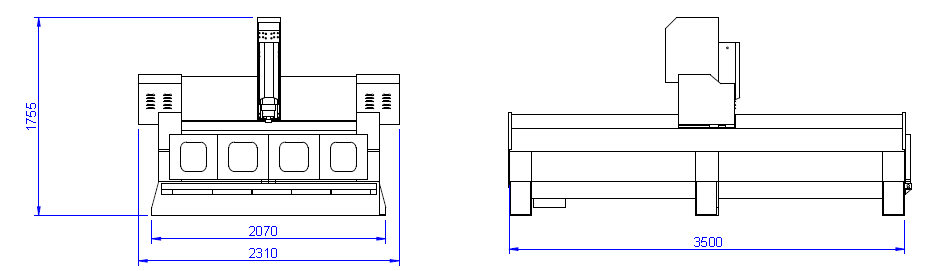

Size:

Details Show of Stone CNC Carving Machine

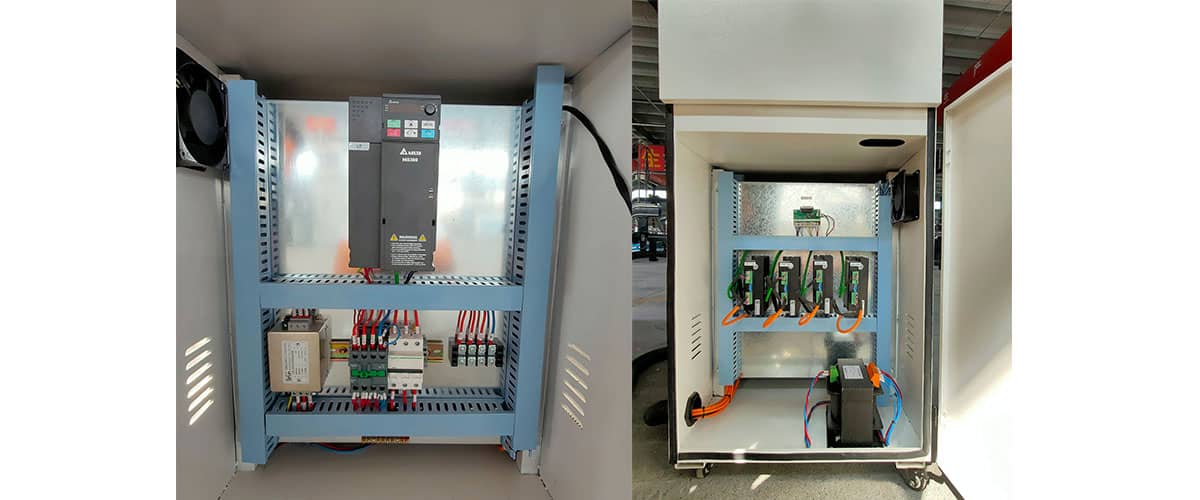

1、Control System

(DSP hand controller is optional) NCStudio control system is suitable for a variety of complex mold processing, advertising and decoration, cutting and other industries, with the advantages of simple and reliable operation, easy to learn. In addition to the manual, stepping, automatic and return to mechanical origin functions, the CNC system also has unique functions such as simulation, dynamic display tracking, Z-axis automatic tool setting, breakpoint memory (program skip execution) and rotary axis machining.

2、T-slots and PVC table

(Vacuum table is optional) Reaying used aluminum alloy profiles with light weight, high strength, corrosion resistance, small deformation, strong fire resistance and long service life, which maintain the inherent color and luster for a long time.Reaying also used a thickened PVC board with good tensile, flexural, compressive and impact resistance

3、Water-cooling Spindle system

(Air-cooling spindle is optional) Reaying chosen TDG 3.2KW water-cooling spindle which has the advantages of high speed, high precision, large output power and low noise.

Stone CNC Machine Parameters:

| Working area | 1300*2500*500mm |

| Spindle | HQD 3/4.5/5.5/7.5KW water cooling spindle |

| Inverter | Fuling |

| Motor | Stepper motors |

| Driver | Stepper driver 860H |

| Control System | Nc studio control system |

| Table | Aluminum table with water tank |

| Oil lubrication | With |

| Limit | Omron limit |

| Transmission | XY axis helical rack Z axis Taiwan ball screw |

| Rail | X, Y, Z axis Taiwan HIWIN Square guide rail |

| Screw | Z axis TBI ball screw |

| Bed | Thick steel welded structure |

| Voltage | 3 phase/380V |

| *Some specifications can be customized upon request, please contact us. | |