Views: 8 Author: Site Editor Publish Time: 2021-10-07 Origin: Site

Handheld fiber laser welding machine uses a pulsed laser with a wavelength of 1064nm generated by the laser to radiate the surface of the workpiece after beam expansion, reflection, and focus. The surface heat is diffused to the inside through heat conduction, and the width, energy, and peak power of the laser pulse are precisely controlled through digitalization. With parameters such as repetition frequency, the workpiece is melted to form a specific molten pool, so as to realize the laser welding of the workpiece, and complete the precision welding that cannot be achieved by the traditional TIG welder & MIG welder.

LASER is an acronym for “Light Amplification by the Stimulated Emission of Radiation" which produces a sharp, focused light beam that melts a very small area of metal. The benefit of fiber laser technology is that very little heat is generated at the weld point, allowing users to easily weld 0,05mm (.002”) away from the most complicated and intricate component parts without damaging heat sensitive materials.

Operators hold parts in their hands while viewing the application through a stereo-microscope in the welding chamber. An internal cross-hair allows the operator to easily align and weld the parts at the correct location.

So, what are the advantages of fiber laser welding machine compared to ordinary laser welding machine?

Features and advantages of ordinary welding machine

1. Laser welding is a new type of welding method, which is mainly aimed at welding machines for thin-walled materials and precision parts. It can realize welding methods such as spot welding, butt welding, overlap welding, and sealing welding;

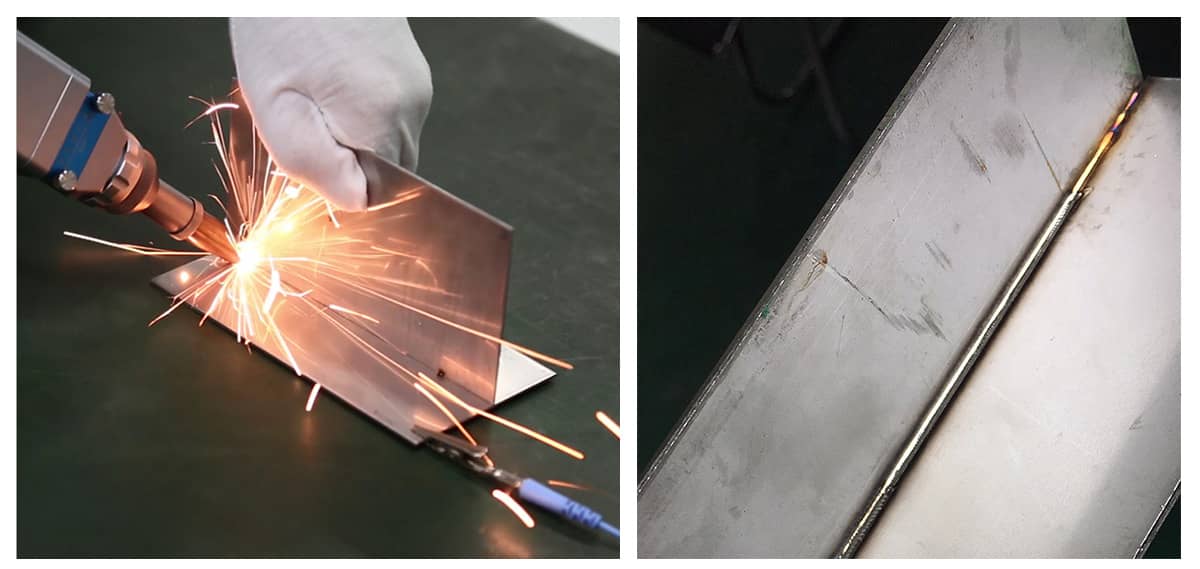

2. The width of the laser welding seam is small, the heat-affected zone is small, and the deformation is small;

3. The laser welding speed is fast, the weld seam is smooth and beautiful, no treatment or simple treatment is required after welding, and the weld seam quality is high;

4. Laser welding, no air holes, accurate control, small focus spot, high positioning accuracy, and easy to realize automation.

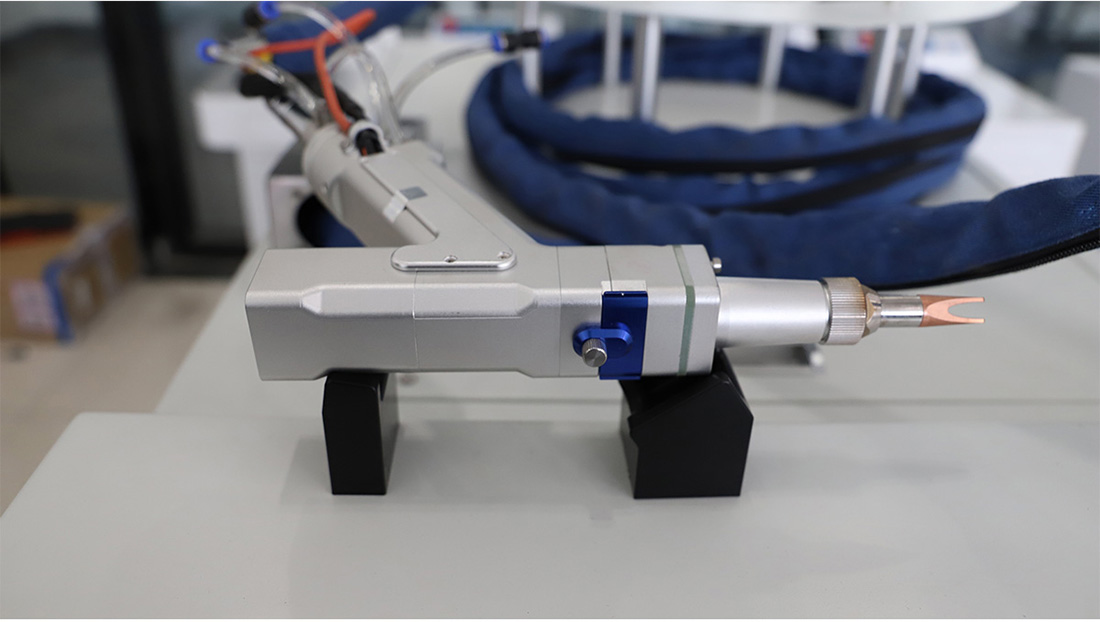

Handheld fiber laser welding machine Configuration

The Power of Hot Light

LaserStar Technologies’ development of the “free-moving” concept enable users to eliminate costly fixturing devices, benefit from pin-point accuracy,increase the range of assembly and repair applications and minimize the potential hazards of heat damage. The resulting weld is considerably stronger than a traditional solder joint. Manual Welding Fiber Laser Systems are ideal for the smallest workshop to large industrial manufacturers. Common industry applications include:

Spot Welding

Seam Welding

Mold Repair Welding

Medical Device Components

Micro Welding

Battery Welding

Computer Components

Aerospace and Electronics

Automotive and Micro Components