| Availability: | |

|---|---|

Handheld Laser Welder Descriptions :

Handheld Laser Welder features 1000W, 1500W, or 2000W fiber laser beam for welding joints of butt, edge, corner, tee, and lap. The portable handheld fiber laser welding machine will take over the traditional argon arc welding, MIG & TIG welding, and electric welding for metal joints.

Hand Held Fiber Laser Welder Advantages:

★ Pure hand-held laser welding machine is a hand-held welding head, which connects the optical fiber to the hand-held welding head, and then realizes various welding of products.

★ The advantage of the handheld laser welding machine is that for products with larger specifications and longer welding lengths, such as sinks and stainless steel kitchen cabinets, they can be welded without placing these products on the workbench.

★ The welding is flexible and easy to operate. In addition to repairing large molds, large machines can also achieve long-distance welding, which can be welded without disassembling the product.

★ It has the advantages of simple operation, beautiful welding seam, fast welding speed, and no consumables. It can perfectly replace traditional argon arc welding, electric welding and other processes for welding thin stainless steel plates, iron plates,galvanized plates and other metal materials.

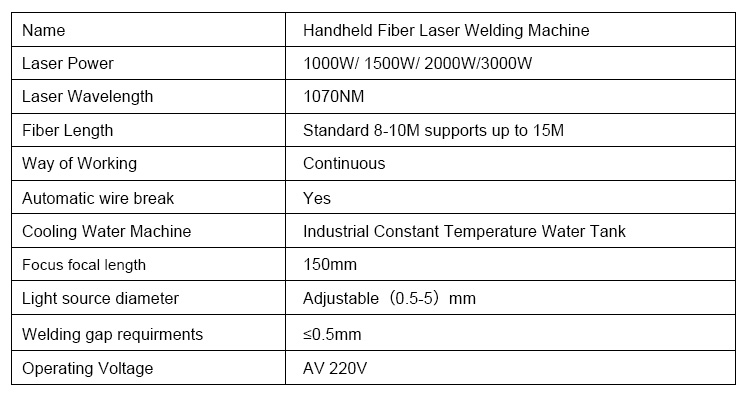

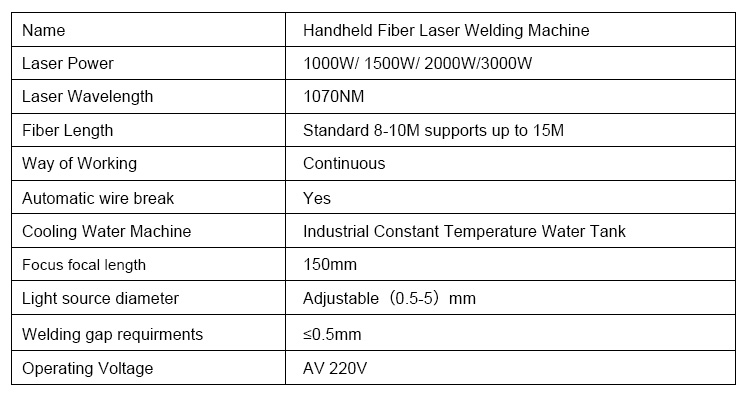

Handheld Laser Welding Machine Parameters:

Handheld Laser Welding Machine Configuration:

Hand-held welding laser head

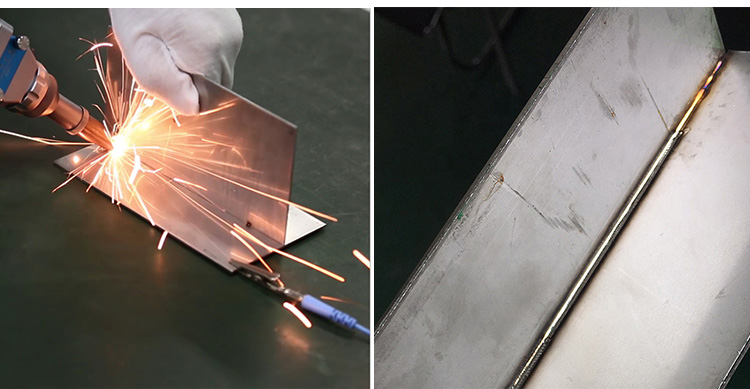

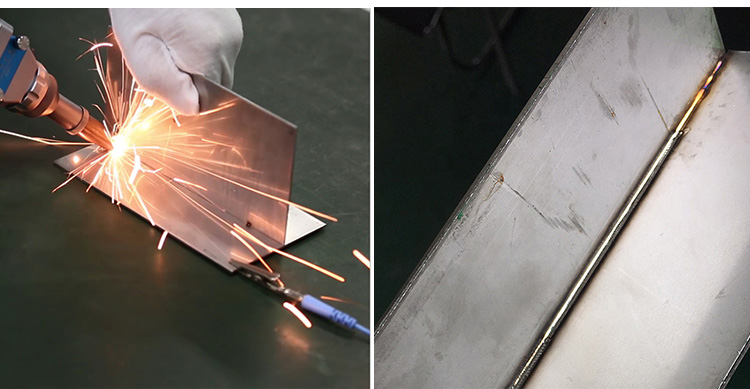

The handheld laser welding machine can perform long-distance laser welding of large workpieces. The heat affected area is small during welding, and it will not cause deformation, blackening, and traces on the back of the workpiece. The connection depth is large, the welding is firm, and the melting is sufficient. There is no depression in the joint between the raised part of the molten material in the bath and the substrate! The welding speed is fast, 2-10 times faster than traditional welding, and one machine can save at least 2 welders a year.

The handheld laser welding machine can perform long-distance laser welding of largeworkpieces. The heat affected area is small during welding, and it will not cause deformation, blackening, and traces on the back of the workpiece.

The connection depth is large, the welding is firm, and the melting is sufficient.

There is no depression in the joint between the raised part of the molten material in the bath and the substrate!

The welding speed is fast, 2-10 times faster than traditional welding, and one machine can save at least 2 welders a year.

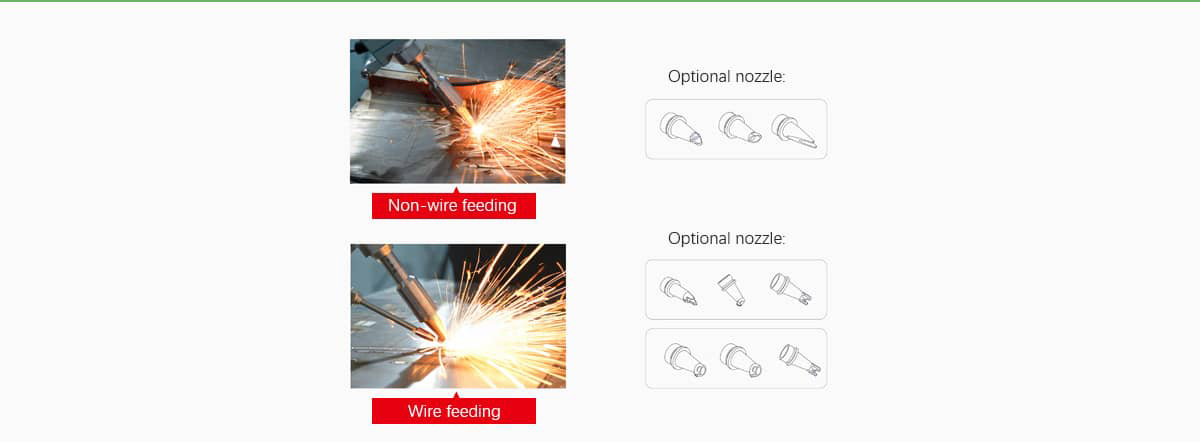

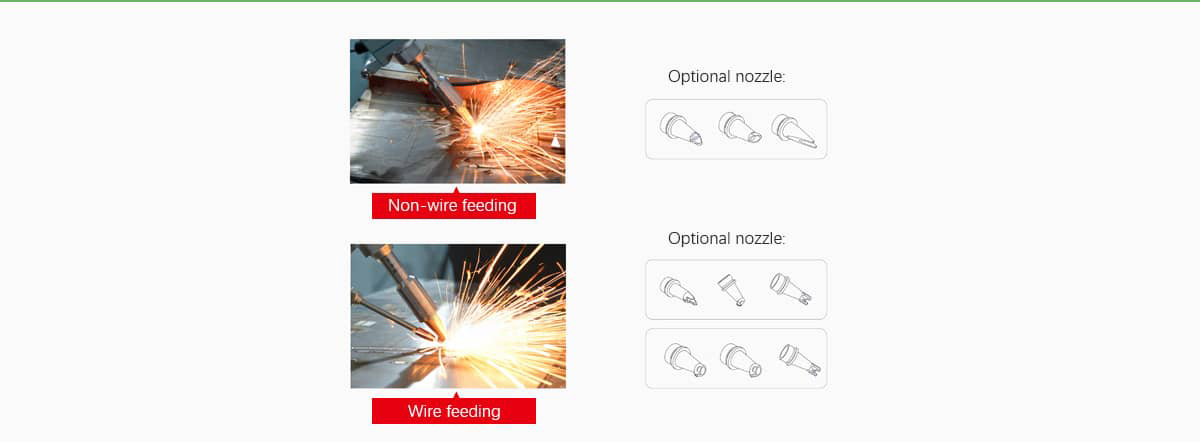

iGoldencnc’s handheld laser welding machine has two welding modes.

Customers can choose between wire feeding or non-wire feeding according to their own products.

The switching is simple and practical.

Laser Source

The laser adopts water-cooled heat dissipation and rack-mounted chassis design.

It has many advantages such as high electro-optical conversion efficiency, low energy consumption, compact structure, adjustment-free maintenance, and easy integration for customers.

It is industrial laser welding and other Ideal light source for application.

HANLI Chiller

1. The cooling capacity is up to 1400W, and environmentally friendly refrigerants can be used;2. Small size, long life and durable, easy to operate;3. The temperature control accuracy can reach +0.3C;4. The intelligent thermostat has two temperature control modes, which are suitable for different use occasions; it has a variety of settings and fault display functions;5. With multiple alarm protection functions

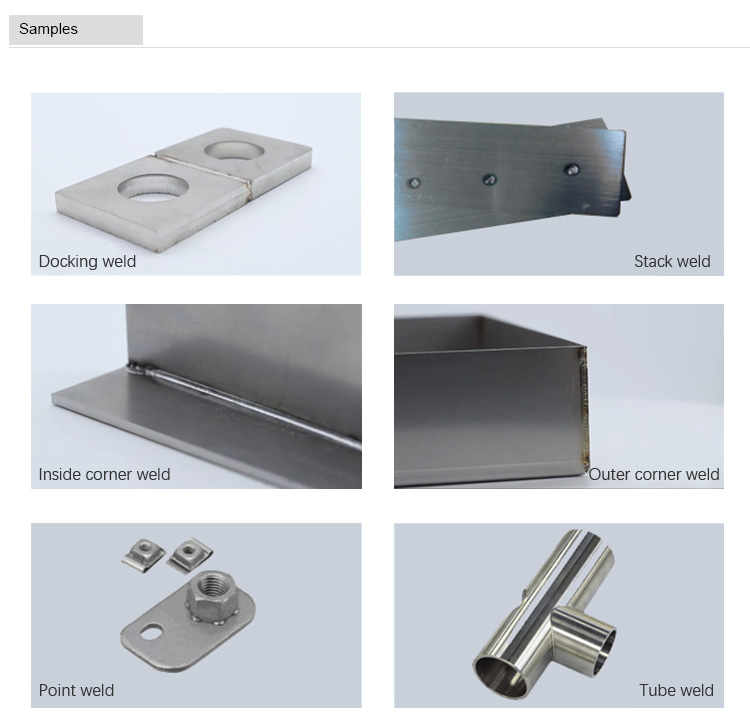

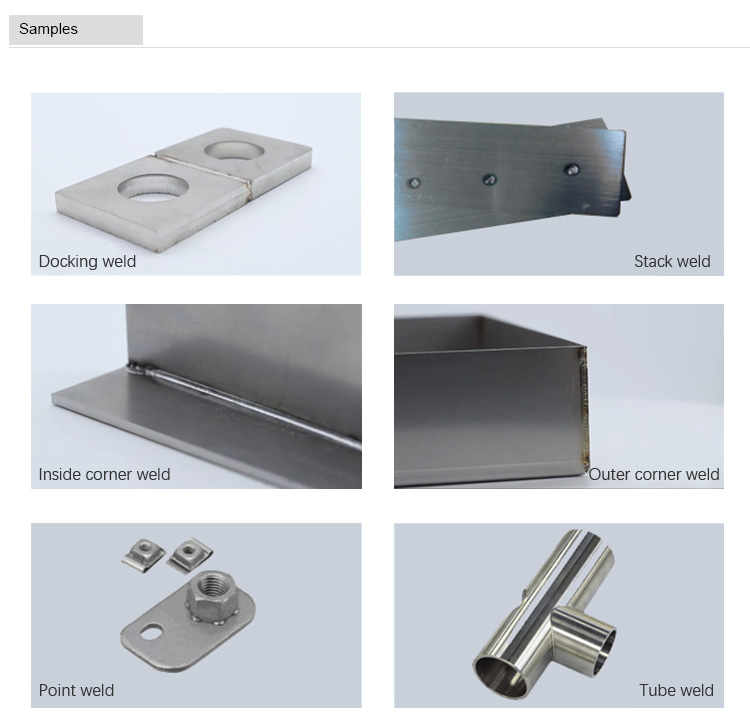

Fiber Handheld Laser Welding Machine Application:

Suitable for welding of stainless steel, iron sheet, aluminum, copper, alloy, steel, diamond equivalent materials or dissimilar materials, cabinets, kitchens, stair elevators, shelves, ovens, stainless steel doors and windows guardrails, distribution boxes, Stainless steel household and other industries.

iGOLDENCNC Factory View

Customer Visiting

iGOLDENCNC Service

| Pre-sales |

| > Free pre-sale consultation |

| > Free sample testing |

| > Professional CNC solutions |

| > Customer reception |

| > Fast delivery within 7 days(Available in stock) |

| > Customized machines delivered within 30 days |

| After-sales |

| > 2-year warranty |

| > Fast feedback and after-sales service in 12 hours |

| > Fast spare parts and technical assistance |

| > Free training services |

| > Special design, customized, OEM order |

Handheld Laser Welder Descriptions :

Handheld Laser Welder features 1000W, 1500W, or 2000W fiber laser beam for welding joints of butt, edge, corner, tee, and lap. The portable handheld fiber laser welding machine will take over the traditional argon arc welding, MIG & TIG welding, and electric welding for metal joints.

Hand Held Fiber Laser Welder Advantages:

★ Pure hand-held laser welding machine is a hand-held welding head, which connects the optical fiber to the hand-held welding head, and then realizes various welding of products.

★ The advantage of the handheld laser welding machine is that for products with larger specifications and longer welding lengths, such as sinks and stainless steel kitchen cabinets, they can be welded without placing these products on the workbench.

★ The welding is flexible and easy to operate. In addition to repairing large molds, large machines can also achieve long-distance welding, which can be welded without disassembling the product.

★ It has the advantages of simple operation, beautiful welding seam, fast welding speed, and no consumables. It can perfectly replace traditional argon arc welding, electric welding and other processes for welding thin stainless steel plates, iron plates,galvanized plates and other metal materials.

Handheld Laser Welding Machine Parameters:

Handheld Laser Welding Machine Configuration:

Hand-held welding laser head

The handheld laser welding machine can perform long-distance laser welding of large workpieces. The heat affected area is small during welding, and it will not cause deformation, blackening, and traces on the back of the workpiece. The connection depth is large, the welding is firm, and the melting is sufficient. There is no depression in the joint between the raised part of the molten material in the bath and the substrate! The welding speed is fast, 2-10 times faster than traditional welding, and one machine can save at least 2 welders a year.

The handheld laser welding machine can perform long-distance laser welding of largeworkpieces. The heat affected area is small during welding, and it will not cause deformation, blackening, and traces on the back of the workpiece.

The connection depth is large, the welding is firm, and the melting is sufficient.

There is no depression in the joint between the raised part of the molten material in the bath and the substrate!

The welding speed is fast, 2-10 times faster than traditional welding, and one machine can save at least 2 welders a year.

iGoldencnc’s handheld laser welding machine has two welding modes.

Customers can choose between wire feeding or non-wire feeding according to their own products.

The switching is simple and practical.

Laser Source

The laser adopts water-cooled heat dissipation and rack-mounted chassis design.

It has many advantages such as high electro-optical conversion efficiency, low energy consumption, compact structure, adjustment-free maintenance, and easy integration for customers.

It is industrial laser welding and other Ideal light source for application.

HANLI Chiller

1. The cooling capacity is up to 1400W, and environmentally friendly refrigerants can be used;2. Small size, long life and durable, easy to operate;3. The temperature control accuracy can reach +0.3C;4. The intelligent thermostat has two temperature control modes, which are suitable for different use occasions; it has a variety of settings and fault display functions;5. With multiple alarm protection functions

Fiber Handheld Laser Welding Machine Application:

Suitable for welding of stainless steel, iron sheet, aluminum, copper, alloy, steel, diamond equivalent materials or dissimilar materials, cabinets, kitchens, stair elevators, shelves, ovens, stainless steel doors and windows guardrails, distribution boxes, Stainless steel household and other industries.

iGOLDENCNC Factory View

Customer Visiting

iGOLDENCNC Service

| Pre-sales |

| > Free pre-sale consultation |

| > Free sample testing |

| > Professional CNC solutions |

| > Customer reception |

| > Fast delivery within 7 days(Available in stock) |

| > Customized machines delivered within 30 days |

| After-sales |

| > 2-year warranty |

| > Fast feedback and after-sales service in 12 hours |

| > Fast spare parts and technical assistance |

| > Free training services |

| > Special design, customized, OEM order |