Views: 7 Author: Site Editor Publish Time: 2021-09-13 Origin: Site

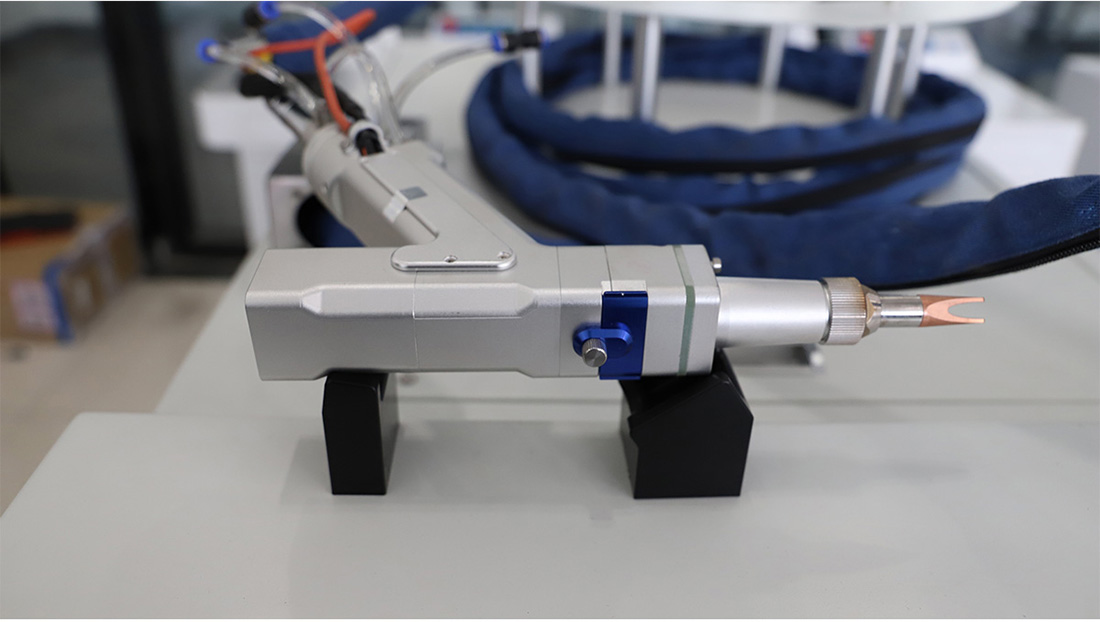

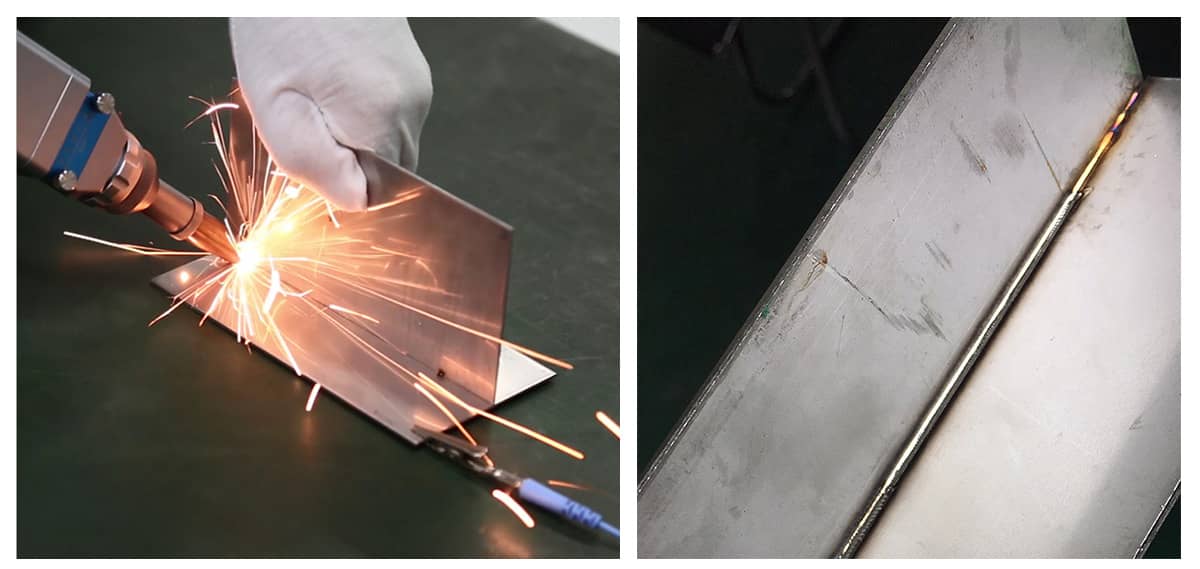

The handheld laser welding machines equipped either with fourth generation wobble welding torch, greatly improving the joint strength and quality of welding and obtaining better weld formability.Handheld laser welding machine can do spot welding, straight seam welding, overlap welding, circumferential welding and welding of any track. Machine also equipped wirh automatic wire feeder. Compared with traditional argon arc welding, the efficiency is increased by more than 50%.

Replacing the old thermal welding systems with a hand-held type weld gun, not only facilitates the welding of molds, advertising characters, kitchen utensils, doors and windows, etc., but also makes laser welding possible in outdoor operations, the welding ability expands from small light workpieces to large bulky objects that are difficult to move, such as stainless steel silos, stainless steel spiral air ducts, chimney pipes, auto steel pig feeders, almost no size limitations, which indicates that the traditional welding of electric welding, argon arc welding, etc. will definitively be replaced by fiber laser welding.

Handheld laser welding machine has the advantages of simple operation, beautiful weld seam, fast welding speed, and no consumables. It can be used for welding various metals sheets and tubes: such as stainless steel plates, iron plates, galvanized plates and CS plates, aluminum plates, brass plates, other metal sheets and tubes.

1.The swaying welding head has a strong advantage in high-reflective material welding,wide range of application,it is very cost effective;

2.The welding head adopts motor-driven X- and Y-axis vibrating lenses, it has various swing modes and able to work on irregular shapes, larger welding spot and other processing parameters setting can improve markedly in welding quality;

3.The internal structure of the welding head is completely sealed to avoid dust contamination of the optical part

4.Equipped with air curtain components to reduce contamination of dust and splash residues.

5.The protective lens has a drawer structure and is easy to replace. Can be equipped with various QBH connector laser sources;

Laser Welding Machine Configuration

The advantage of Laser Welding Machine 2000w wobble head

1. The process that the conventional head can not complete, the dithering head only needs to use about

70% of the power, so that the cost of the laser can be saved;

2 Wobble welding back and forth through the galvanometer motor, so that the bubbles with large impurities

can reduce bubbles, frying, splashing, etc.

3 In the case of irregular gaps, the requirements for the fixture can be reduced.

The conventional oscillating head welding gap is generally 0.2 mm, and light exceeding this width directly

passes through. The width of the gap that can be welded by the oscillating head can reach 0.5mm,

but the conventional welding head can only be welded to 0.2mm. There is no galvanometer motor in

the welding head, so there is no swing. The welding effect is not good, the welding process is limited.

Laser Welding Machine 2000w applications:

Laser Welding Machine is widely used in mobile phone battery shell, houshold appliances,electronic components, mobile communication, hardware products, automotible accessories, glasses, kitcen industry , advertisement, stainless aluminum windows and doors, medical equipment, thermal cups and etc. other industries.

What temperatures are generated during Laser Welding Machine?

To be able to weld a material, a temperature just above its melting point must be reached. In conventional welding processes, the melting temperature of the material is therefore a limiting factor: Not every material can be processed with every welding process. Only electric welding has a certain scope as to the intensity of spot heat it can emit at its electrodes. Laser beam welding is different: Of all welding processes, it offers the greatest flexibility in terms of welding temperature. This overview of commonly used materials and their melting points illustrates the range of materials that can be processed by laser beam welding

Plastics: 150 to 350 °C

Aluminum: 600°C

Glass: 600 to 800°C

Copper: 1085 °C

Steel: 1400 °C