Views: 6 Author: Site Editor Publish Time: 2022-06-15 Origin: Site

Wood carving is an ancient art form that has captivated artists and craftsmen for centuries. Traditionally, wood carving was a labor-intensive process that required hours of meticulous handwork. However, with the advent of technology, wood carving machines have revolutionized the industry. These machines, equipped with advanced cutting tools and computer-controlled precision, allow artists and hobbyists to unleash their creativity and bring intricate wood designs to life.

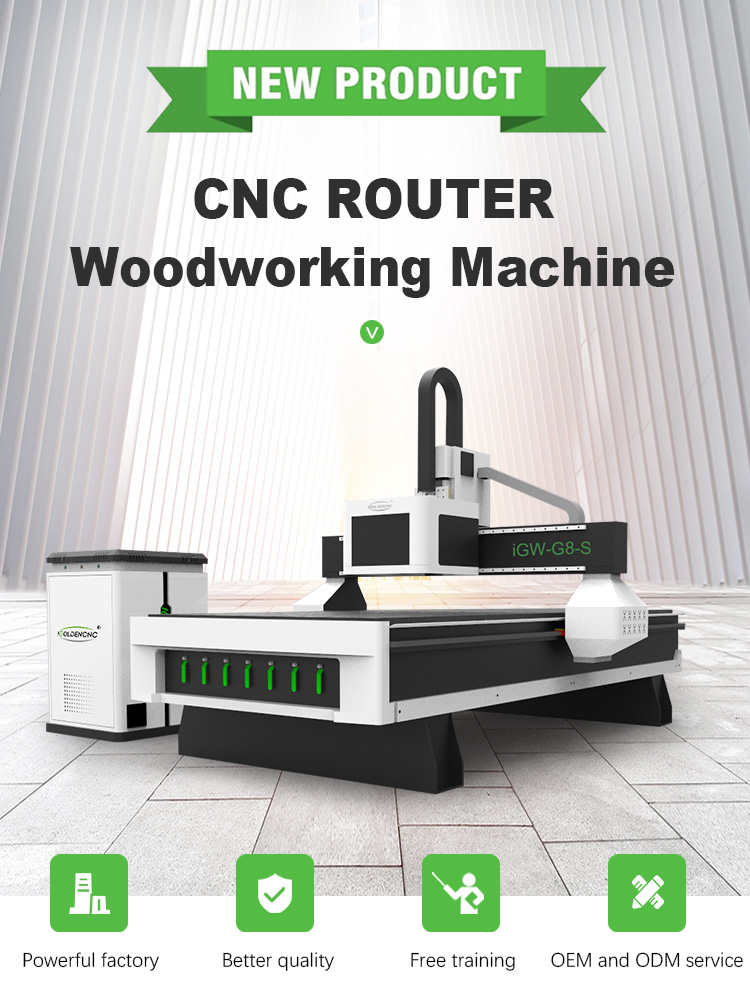

CNC engraving machine is more and more popular, we all find it brings convenience, so woodworking engraver has what advantages, let us have a look.

A wood carving machine, also known as a CNC wood carving machine, is a computer-controlled device that automates the process of carving intricate designs into wood. These machines utilize cutting tools, such as routers or spindle motors, that are guided by computer software. The software translates the digital design into precise movements of the cutting tool, allowing for detailed and accurate carving.

1. Accurate carving:

The wood carving machine near me is controlled by the computer, and the computer is used for engraving. The layout of the computer is set to ensure the accuracy and error of each process.

2. Simple operation:

The central main control system of the CNC engraving machine is based on the imaging operating system to terminally issue engraving commands. This requires workers to put the material on the machine tool and then activate the switch.

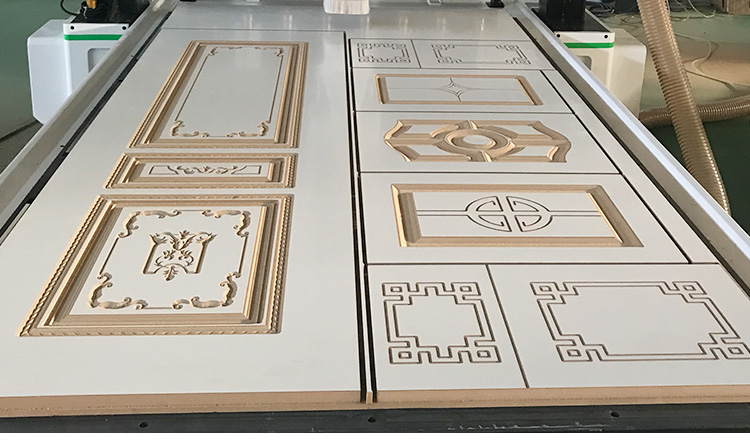

3. Diverse patterns:

The woodworking engraver can operate all kinds of complex engraving without difference.

4. Raw material saving:

The engraving machine data is accurate without errors, so it will not cause the loss of raw materials and reduce the cost.

A wood carving machine offers numerous advantages over traditional hand carving methods. Here are some of the key benefits:

Precision and Accuracy: Wood carving machines provide unparalleled precision and accuracy. The computer-controlled movements ensure that each cut is consistent and exact, eliminating human error and producing high-quality results.

Time Efficiency: Wood carving machines significantly reduce the time required to complete a carving project. The automation of the carving process allows for faster and more efficient production, enabling artists and woodworkers to take on larger projects and meet tight deadlines.

Versatility: Wood carving machines can handle a wide range of wood types, from softwoods like pine and cedar to hardwoods like oak and mahogany. This versatility allows artists to explore different textures, grains, and colors in their designs.

Complex Designs and Intricate Details: Wood carving machines excel at creating complex designs and intricate details that would be challenging to achieve by hand. The precision and repeatability of the machine allow artists to push the boundaries of their creativity and explore intricate patterns, textures, and depths.

Conservation of Wood: Wood carving machines optimize the use of wood, minimizing waste and maximizing the yield from each piece. The ability to program the machine to cut with precision reduces the chances of errors and material loss, making it an environmentally friendly option.

Wood carving machines have found applications in various industries and artistic endeavors. Here are some of the areas where they are commonly used:

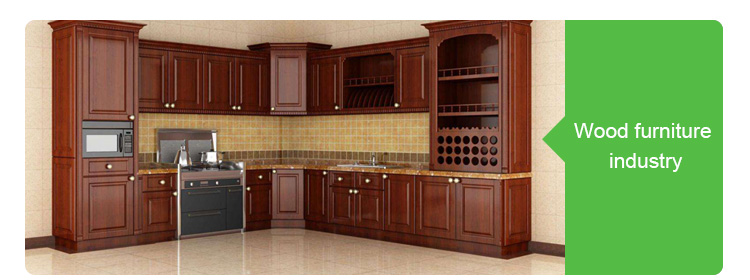

Furniture Design and Production: Wood carving machines play a crucial role in the design and production of furniture. They allow for the creation of intricate patterns and decorative elements on chair backs, table legs, cabinet doors, and other furniture components.

Artistic Sculptures and Figurines: Wood carving machines have opened up new possibilities for artists to create intricate sculptures and figurines. The precision and accuracy of the machine enable artists to bring their visions to life with intricate details and textures.

Architectural Details: Wood carving machines are used to create architectural details in buildings, such as ornate moldings, cornices, and decorative panels. These machines allow for the replication of intricate historical designs or the creation of custom designs to suit modern architectural styles.

Sign Making: Wood carving machines are widely used in the sign-making industry. They can carve intricate lettering, logos, and designs onto wooden signs, providing a professional and eye-catching finish.

Crafts and Hobby Projects: Wood carving machines have become popular among hobbyists and craft enthusiasts. They allow individuals to explore their creativity and create personalized wooden crafts, such as jewelry boxes, picture frames, and decorative items.

·Service life of machine up to a maximum of 20 years.

The machine comes standard with 4 imported knife, automatic tool change, save manual tool changing time, improve work efficiency

Suction pressure integration platform, 7.5KW vacuum pump equiption, the pump is assembled with relief valve and silencer, fix well material, In the working process the material does not vibrate, so it can improve the cutting surface finish.

The double-check lathe bed pass anneal and heat treatment, to ensure that the use of solid shape.

A world-class transmission YASKAWA servo drive motor with high speed and precision drive achieve a maximum speed of 5000 / rpm, also uses a high-resolution serial encoder (16,17bits) to improve the positioning accuracy. Use D Q axis conversion current control system, torque control precision (repeatability) also increased by ± 5% to ± 2%.

PMI 3220 XY axis adopt imported ballscrew with high precision and smooth transmission to improve the processing finish.

Excellent electromechanical design and other electrical accessories with famous international brands.

Gantry of fixing structure, transom fixed, moving platform, adopt imported gantry milling and planer finishing, improve the overall accuracy of the machine assembly.

It has a breakpoint, continued carving capabilities.

Intelligent protection work table to prevent the wrong operation and other possible surface damage. Intelligent processing cross-border protection, to prevent mechanical collision phenomenon caused by the design surface over the processing area.