Views: 24 Author: Site Editor Publish Time: 2022-01-24 Origin: Site

The 4 axis cnc wood router has all the same axes as a 3-axis router plus the additional A-axis that rotates the spindle around the X-axis up to 180 degrees during the cutting process.

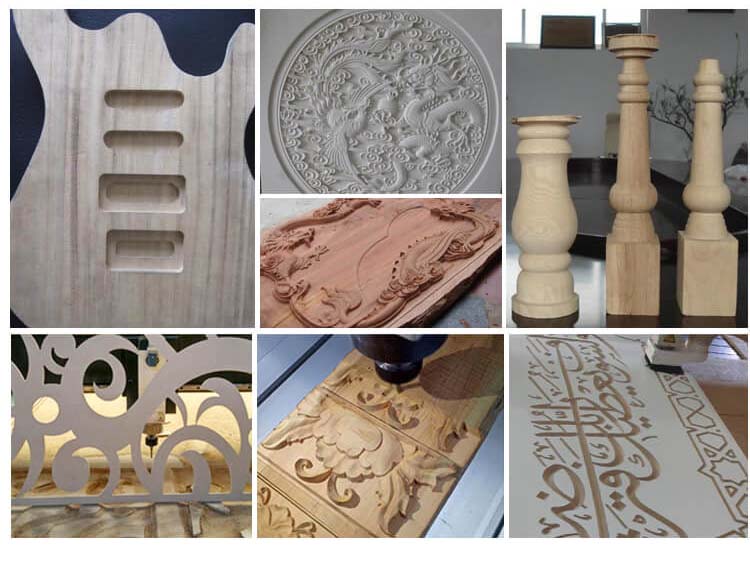

This rotational axis allows cuts to be executed on multiple sides of the workpiece without resetting, while a 3-axis router can only perform cuts to one side of the same piece at a time. 4-axis CNC routers are the preferred method for advanced, intricate cuts and carvings like those often seen in furniture, musical instruments, cabinetry, and more.

The 4 axis cnc wood router is now favored by more and more customers, because the 4 axis CNC router machine can almost meet all the needs of CNC machine Industry. For example, cutting, carving, digging, fine carving, 3D carving, 2D carving and other processing methods. So do you know the advantages of CNC 4 axis router machine?

1. Higher production efficiency

The 4 axis cnc wood router has high production efficiency, can process workpieces efficiently, and can effectively reduce the interference caused by man-made in the processing process, so it can reduce production time and improve production efficiency .

2. Simplified work process

Because of the high degree of automation of the 4 axis milling machine, it can greatly simplify the processing of products by the workers, greatly save the workers’ time and energy, and simplify the processing process.

3. Higher cutting accuracy

The 4 axis cnc wood router is generally equipped with a high-power spindle. This spindle has high cutting accuracy and can engrave high-precision products. After the code is confirmed, the 4 axis CNC mill machine can produce in a short time Produce multiple products.

4. Processing is more flexible

4 axis cnc wood router involves the same process involved in 3-axis machining, where a cutting tool is used to remove material from the workpiece to produce the desired shape and contour. However, in four-axis machining, milling is performed on an additional axis. The 4-axis CNC milling machine kit runs on the X, Y, and Z axes like a 3-axis machine tool, but it also includes rotation around the X axis (called A axis). This is the fourth axis added to our workflow. So the 4 axis CNC router machine can process materials at multiple angles, making the machining process more flexible.

4 axis cnc wood router features:

Multi-spindle engraving: simultaneous work of multiple spindles can be performed on the same pattern, which greatly improves the processing speed. It can also work independently with a single spindle to control production costs.

The bed adopts the overall thickness all-steel structure design, after welding and tempering aging treatment, it has strong rigidity, strong strength and stable rotation, so that it will not be deformed and shaken at high speed for a long time.

The machine tool adopts Taiwan Yintai linear guide rail drive, three-axis full-square rail, which can be re-cut; the international brand microstep subdivision stepper motor and high-speed drive are used to ensure the machine runs at high speed for a long time.

The embedded PIC CNC system is used to seamlessly integrate the machine tool and the computer. The operation is simple. The unique intelligent budget rule is that the motor fully utilizes the high-speed potential, the synchronous processing of curved lines is more perfect, and the worry-free operation for a long time: with power off , Continuous breakpoint carving, processing time prediction and other functions, truly humanized design. It perfectly supports the ISO standard G command and precision engraving (ENG) format, and is compatible with processing codes generated by various CAD/CAM design software such as Types/ArtCAM//Wentai.

Designed specifically for customers who require high-volume, small workpiece processing, suitable for processing cabinet doors, artistic relief screens, craft windows, relief craft gifts, solid wood art murals, woodwork calligraphy carving, art photo frames, electrical countertops, sports Supplies and equipment, violin arcs, non-ferrous metal carving and cutting, and many other industry products.

Applications of 4-axis router :

1. Mould: wood, wax, wood, gypsum, foams, wax.

2. Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

3. The wood products: voice box, game cabinets, computer tables, sewing machines table,instruments.

4. Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti bate board, epoxy resin, ABS, PP, PE and other carbon mixed compounds.

5. Decorate industry: Acrylic, PVC, MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process