Views: 19 Author: Site Editor Publish Time: 2021-09-29 Origin: Site

This model machine can use 1500W, 2000W, 3000W, 4000W, 6000W and 8000W laser power fiber laser cutting machine

Fiber Cutting Machine main parts:

Laser source+laser cutting head+servo motor+motor reducer+plate welding machine bed+beam+guide rail+rack and pinion+independent electric control cabinet+exhaust fan+water chiller.

According to the data in the past few years, the speed of 4KW laser cutting machine has increased by nearly 400% in 8mm stainless steel plate. In 20 mm thick stainless steel, the speed of 12 kilowatts is 114% higher than that of 10 kilowatts!

In terms of economic benefits, the price of 4000w laser cutting machine is higher than that of 6kW machine tool by 40%, but the bit time output efficiency is about twice that of 6kW machine tool.

In addition, 10kW fiber laser cutting can maintain 182mm / s surface cutting in the use of carbon steel cutting, is twice the standard cutting rate!

If you want lower cost and higher efficiency, you must first use the 10000 watt fiber laser cutting machine. Thus, the market demand for wanwa laser cutting machine will continue to increase!

High power fiber cutting machine era is the inevitable trend!

In 2012, 4000w Fiber Cutting Machine technology appeared for the first time. Up to now, 10000W fiber laser cutting machine has started its market. Chinese laser cutting machine manufacturers have followed the improvement of laser cutting output power, developed and designed high-power laser cutting processing in a short time, and promoted the arrival of high-power period in China's laser cutting sales market!

4000w Fiber Cutting Machine from G.weike laser used to cut metal materials special design

1.Clamp Design

It adopts an electric clamp design on both sides and it can modulate the center automatically. The diagonal adjustable range is 20-200mm.

2.Exchanging Platform

It adopts an up and down exchange platform, and the converter is responsible for controlling the exchanging motor.

The machine is able to finish the platform exchanging within 15s.

3.3rd Generation Aviation Aluminum Gantry

It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding. After aging treatment, its strength can reach 6061 T6 which is the strongest strength of all gantries. Aviation aluminum has many advantages, such as good toughness, light weight, corrosion resistance, anti-oxidation, low density, and greatly increase the processing speed.

4.Dual Use and Cost-saving

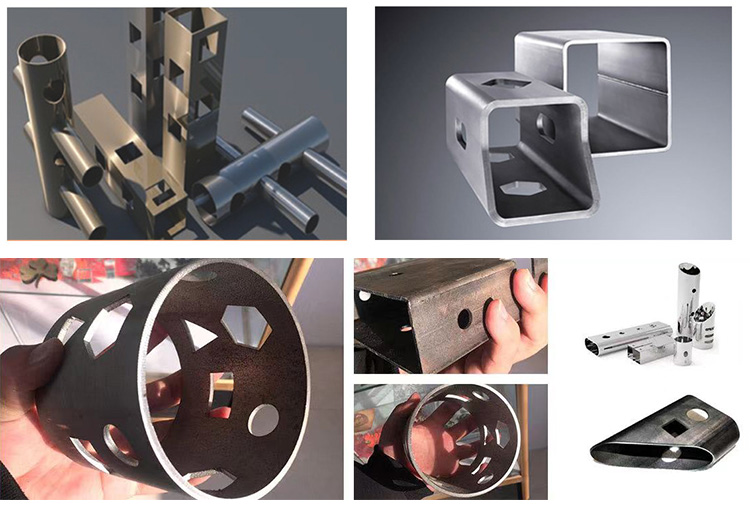

LF3015GCR fiber laser cutting machine can not only cut metal plates, but also metal pipes. It has many uses and can save the space of more than 50%, which effectively improve productivity.

5.Fractional Automatic Support Installation

It employs intelligent tube support design, which can solve the deformation problems in the process of long tube cutting.

Fiber Cutting Machine Parameter Configuration

Model | IGR-T |

Chuck | ①240 front and rear dual pneumatic chucks; ②Range of clamping pipe diameter: 20mm-240mm; ③Transmission mode: gear transmission; ④Rated speed: about 80r/min; (For round pipes according to the outer diameter, for rectangular pipes according to the largest diagonal) |

Bed | Tube welded bed |

Motor | Yaskawa Servo Motor |

Reducer | SHIMPO Reducer |

Rail | TaiWan HIWIN |

Rack | T-WIN helical gear |

Y-axis travel | ≈7m, applicable tube length ≤6m |

X-axis travel | 240mm |

Z-axis travel | 220mm |

Support form | Pneumatic variable diameter wheel support |

Rated travel speed | Y-axis about 40m/min, XZ-axis about 30m/min |

Dimensions | 12.5m(L)×2.15m(W)×2.5m(H) |

System | Cypcut Laser cutting system |

Laser head | RayTools BM109 |

Laser | Raycus 1.5KW |

Operation console | Industrial computer + touch screen |

Scope of Application