Views: 39 Author: igoldenCNC Publish Time: 2023-05-24 Origin: igoldencnc

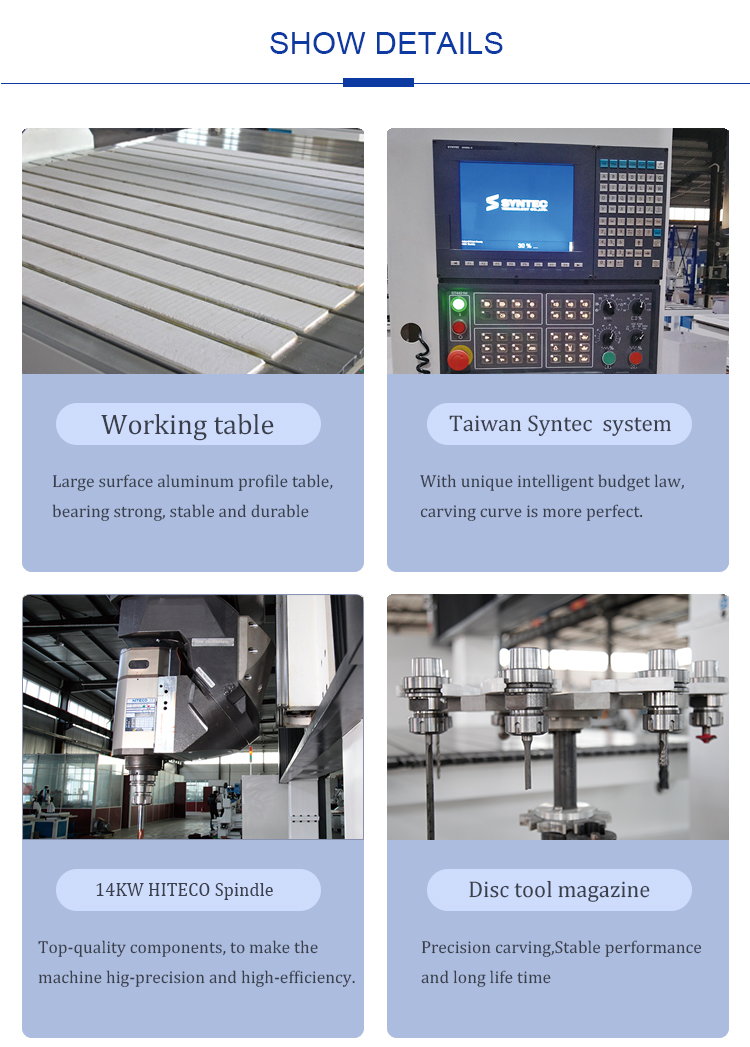

This 5 axis CNC router machine is a 5 axis industrial CNC machining center. And the large 5 axis CNC router machine is designed for industrial use. As a CNC foam wood aluminum router cutter, it can process many materials. The work size of this CNC router machine is can be custom-made, and the length could be as long as 12 meters, and the width of the machine could be as wide as 3 meters, Z working height of the machine could be 2 meters. If you have a large factory, then I think this machine is very suitable for you. It can process almost all kinds of materials and apply to most of the engraving fields. iGOLDENCNC is a well-known 5 axis CNC router manufacturer, if you want to know For more information, please contact us.

By combining these five axes, a 5 axis CNC router machine can achieve complex machining operations and produce intricate parts and components. The simultaneous movement of the axes enables the machine to reach difficult-to-access areas, perform multi-sided machining, and create complex geometries with greater precision and efficiency.

The primary advantage of a 5-axis CNC machine is its ability to machine parts from multiple angles and orientations without the need for repositioning or resetting the workpiece. This capability reduces setup time, improves accuracy, and expands the range of possible machining operations. It allows for the creation of complex shapes, contours, and undercuts that would be challenging or impossible to achieve with fewer axes.

Applications of 5-axis CNC machines include aerospace components, turbine blades, complex molds and dies, sculptural works, and other precision parts that require intricate machining. They are commonly used in industries that demand high-precision and high-efficiency manufacturing processes.

It's important to note that the specific features, capabilities, and sizes of 5-axis CNC machines can vary depending on the manufacturer and model. Different machines may have different work areas, spindle speeds, tool changers, and control systems. Therefore, it's crucial to evaluate your specific machining requirements and consult with suppliers or manufacturers to select the most suitable 5-axis CNC machine for your needs.

Automatic tool changers: These systems can automatically change cutting tools during the cutting process, allowing the machine to perform multiple operations without the need for manual intervention.

Dust collection systems: These systemscan help to reduce the amount of sawdust and debris generated during the cutting process, which can improve air quality and reduce the risk of respiratory problems for operators.

Vacuum tables: These tables use suction to hold the wood material in place during the cutting process, which can help to reduce the risk of movement or vibration that may affect the accuracy of the cuts.

Laser alignment systems: These systems use lasers to help align the wood material and the cutting tool, ensuring that the cuts are made with precision and accuracy.

Rotary devices: These devices can be used to carve cylindrical objects such as table legs, columns, and balusters.

Automatic tool calibration: This feature allows the machine to automatically calibrate the cutting tools for improved accuracy and efficiency.

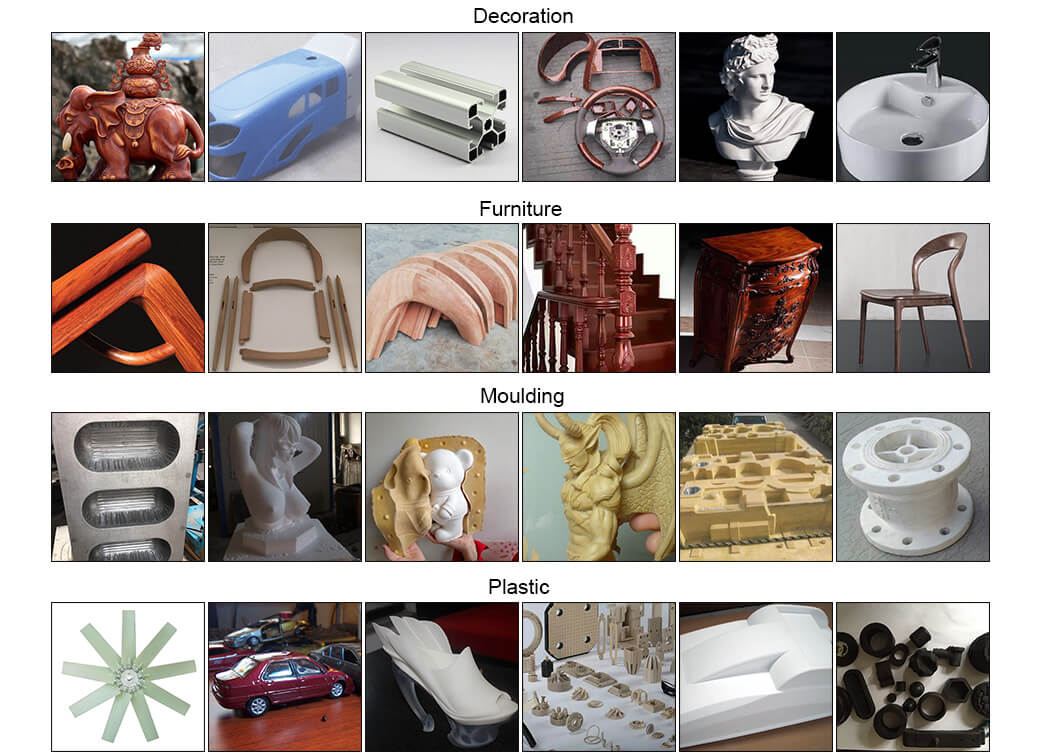

1. Mold making: sculptures, large non-metallic molds, lost molds for cars, wooden ship models, wooden models for aviation, etc., plaster molds, etc.

2. Ship building: ship,yacht, boat and plate making industry.

3. Non-ferrous metals: aluminum, copper, alloy, and other light non-ferrous metals processing.

4. Others: portrait carving, landscape decoration, amusement park cartoon image carving.