Views: 33 Author: Site Editor Publish Time: 2021-09-18 Origin: Site

Laser cleaning machine is the latest high-tech product. Easy to install, operate, easy to achieving automation.. Plug in power, turn on and start cleaning - without chemicals, media, dust, water.

Cleaning with no detergent, no media, no dust, no water. Auto focus, can clean curved surface, gentle cleaning surface. Cleaning resin, oil stain, rust, coating materials, paints on workpiece surface.

Operators can run a workstation where they load parts and trigger the laser process. Our workstations are Class-1 certified so that operators can work safely without wearing PPE. For our handheld devices, operators direct the laser beam manually and need to wear individual laser protection equipment to remain 100% safe.

Features of Laser cleaning machine for rust

1. Fast and concentrated pulses with enormous power impact and gasification of residues on the surface;

2. Laser pulses are very suitable for the removal of organic matter, such as residues in the tire mold fouling;

3. The impact of a short period of time will not cause metal surface heating, no damage to the substrate.

4. Clean or remove the surface paint layer quickly and cleanly;

5. Accurate cleaning and paint removal effect;

6. No damage to the base material;

1、Get Rid of Consumables & Go Green

As a green technology, laser cleaning replaces methods that remove rust with consumables or chemicals. It’s the only solution that meets environmental protection regulations. Plus, pulsed fiber lasers have low power consumption.

laser cleaning machine does generate a small amount of dust in the air. It can be vacuumed instantly with a dust extraction system, which we provide and preconfigure for you if needed.

2、Eliminate Manual Labor

Spending a mass amount of manual labor to clean every single part is inefficient. It is expensive and can be performed more efficiently with robots. Eliminate manual labor through laser cleaning, a technology that can easily be fully or semi-automated.

You can either choose a standard turnkey solution or partner us up with your system integrator for a solution customized for your plant.

3、Minimize Maintenance

Everyone who uses abrasive blasting faces the same problem: their machine is constantly interrupted. Whether it’s for the presence of sand, the nozzle’s condition or its replacement, blasting machines require regular monitoring and maintenance.

Laser rust removal is a non-contact method that continuously removes rust while drastically lowering maintenance costs.

4、Create a Safe Workplace

Lasers in manufacturing environments are extremely safe when integrated with a dust extraction system and a Class-1 laser safety enclosure.

With these things in place, operators who are near the laser system don’t need personal protective equipment for respiratory, hearing or body protection. In addition, they no longer handle dangerous materials.

The working principle of the laser cleaning machine :

It is mainly to ablate the rust, coating, oil and other surface substances on the surface of the product through the instant high temperature corrosion produced by the laser beam on the surface of the product. The laser cleaner machine has a wide range of applications and is basically suitable for any industry. Laser cleaner machine uses high-energy density laser beam to irradiate the surface of the workpiece, so that the dirt, rust or coating on the surface will evaporate or peel instantly, so as to achieve a clean, green, energy-saving and efficient industrial tool. It can quickly remove paint, rust removal, removal of oxides, oil stains, oil stains and product residues, restoration and preservation of historical cultural relics, etc.

Senfeng leiming industrial laser cleaner machine effectively removes the adhesion or surface coating on the surface of the cleaning object at a high speed, so as to achieve a clean process. It is a new technology based on the interaction effect of laser and matter. It is different from traditional mechanical cleaning, chemical cleaning and ultrasonic cleaning (wet cleaning process). It does not require any CFC organic solvents that destroy the ozone layer and is pollution-free,no noise, harmless to the human body and the environment, it is a truly green cleaning technology.

Machine Configuration

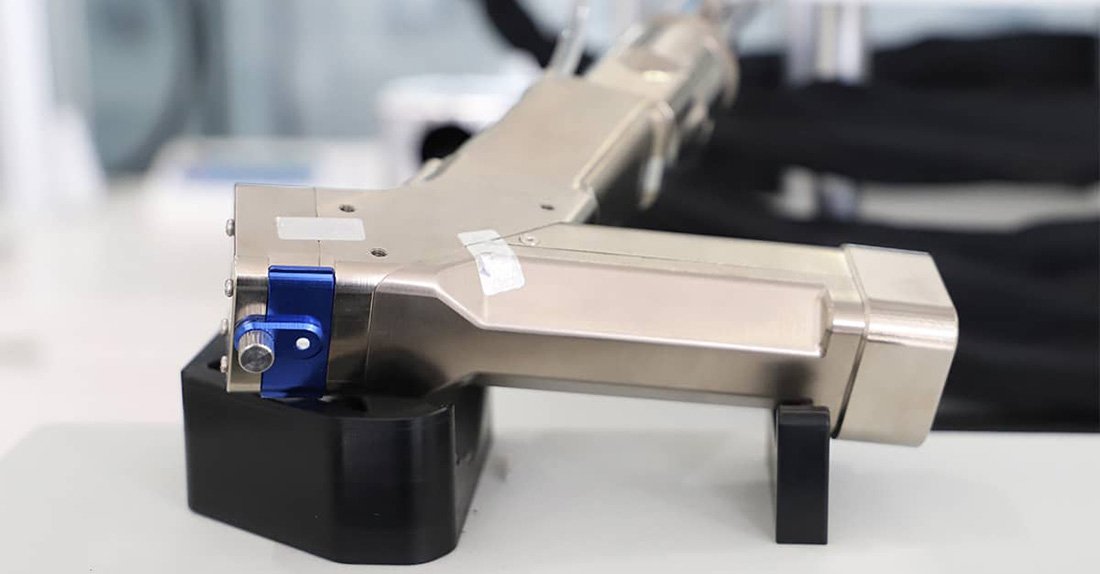

Cleaning machine laser head:

High cleaning cleanliness It can accurately locate and clean contact cleaning, protect thesurface of brittle materials,and effectively remove micron-level pollution particles; green and environmentally friendly, no consumables are required.

This not only means that laser cleaning is effective, but the cleaning process is environmentally friendly.

In addition, it does not use chemical cleaning agents, thus avoiding the damage caused by chemical corrosion to the material.

The high-intensity light pulse generated by the laser that calculates and sets the threshold value forms an interaction between the short-pulse laser and the contaminated layer, resulting in a photophysical reaction.

The beam is absorbed by the contaminated layer on the surface to be treated. The absorption of large energy forms a rapidly expanding plasma (highly ionized unstable gas), which generates shock waves.

The shock waves turn pollutants, oxides, etc. into fragments and gases and are removed to complete the cleaning.

laser cleaning machine application :

Application Area: this kind of handheld laser rust removal machine is widely applied in mold industry, automobile manufacturing, shipbuilding industry, food processing, sewage treatment, rubber tires, petrochemical and other industries.

Application Scope: this laser cleaning machine rust machine can quickly remove paint and remove metal or glass surface coating, rust, and a variety of oxides, grease, resin, glue, dust, stains, production residues, rough metal surface. laser The cleaning rust machine can also remove the greasy dirt, Post-weld oxide and dispose of the residue before welding. Mould cleaning,such as tire mould, electronic mould, food mould. Greasy dirt of the precision parts can be removed after production and processing. All in all, this laser removal machine can quick cleaning of nuclear component maintenance.