Views: 10 Author: Site Editor Publish Time: 2021-11-17 Origin: Site

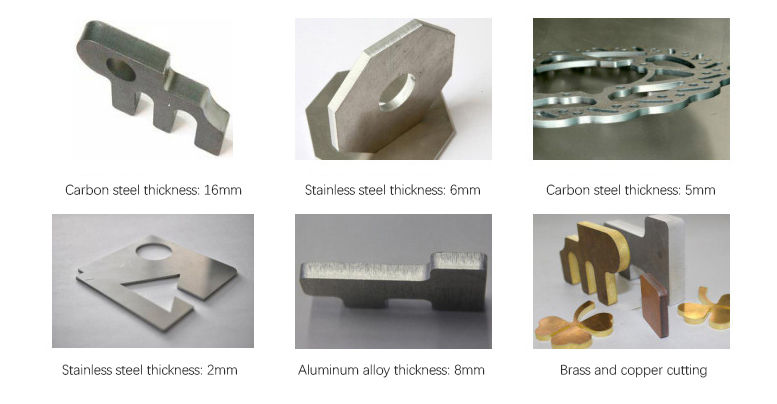

Fiber laser metal cutting machine is used for personalized and custom metal signs, metal arts, metal crafts, metal tags, metal logos, metal words, metal letters of stainless steel, carbon steel, brass, aluminum, alloy, rare metal and other metal materials. The metal laser cutter can be used for cutting both sheet metal and metal tubes.

1. The precision of laser drilling is very fine:

Laser cutting machine can process small holes: 1.00mm~3.00mm; secondary small holes: 0.40mm~1.00mm; super small holes: 0.1mm~0.40mm; micro holes: 0.01mm~0.10mm; secondary micro holes 0.001~0.01mm ; Ultra-micropore: <0.001mm.

2. Laser drilling without consumables: Laser drilling has little effect on the heat of the workpiece, and there is basically no thermal deformation of the workpiece, so as to avoid the collapse of the material when the material is punched and cut. In addition, the laser head will not contact the surface of the material, and there will be no scratches to damage the workpiece, and the workpiece is guaranteed not to be scratched. The use of laser drilling can almost achieve zero consumables.

3. Almost unlimited perforated materials

The laser beam of laser drilling is highly concentrated in space and time, which can reduce the diameter of the spot to the micron level to obtain a high power density, and can perform laser drilling on almost any material. For example, steel plate microporous mesh, stainless steel microporous mesh, aluminum alloy plate microporous mesh, cemented carbide, etc. can be used for micro-hole drilling, no matter what the hardness, it can be used for non-deformation laser drilling.

In addition, laser drilling is not affected by the shape of the material, because the flexibility of laser drilling is good, all can be processed by laser drilling machine for arbitrary graphics, and other profiles can also be punched.

4. The laser drilling speed is fast, and the drilling surface is smooth and free of burrs. Generally, laser drilling does not require secondary processing, which improves production efficiency and reduces production costs.

Features of fiber laser metal cutting machine:

1.Gantry rack double drive system, reinforced welding body. The stress is eliminated by tempering and vibration aging to ensure that the machine deformation tolerance is within 0.02 mm;

2.Crossbeam are made through drawing and finishing process: Lightweight, high rigidity, high dynamic performance;

3.Cutting head has the leapfrog function, parabolic motion between the cutting contours. Automatic frog jump during switching contours, high cutting efficiency;

4.Automatic concentrated lubrication function, automatic lubrication for traditional parts by system control. No manual intervention is needed so as to ensure the accuracy and service life of the moving part.

Machine Parameters

| Model | iGR-FT 3015 | |

| Working area/ Tube length | 3000*1500mm/ 6000mm | |

| X axis stroke | 1500mm | |

| Y axis stroke | 3000mm | |

| Z axis stroke | 300mm | |

| Tube diameter | 20-220mm | |

| Accuracy | X, Y axis positioning accuracy | 0.05mm |

| X, Y axis repositioning accuracy | 0.03mm | |

| Speed | W axis rotate angle | n*360 |

| W axis max. ratate speed | 80rpm | |

| X, Y axis max. running speed | 150m/min | |

| U axis max. positioning speed | 800mm/s | |

| X, Y axis max. accelerated speed | 1.5G | |

| Power supply | Phase | 3 |

| Nominal voltage | 380V | |

| Frequency | 50/60Hz | |

| Protection grade | IP65 | |

| Machine body | Max. working loading | 1000kg |

| Body weight | 2600kg | |

| Size(L*W*H) | 8060*3000*1965mm | |

| Laser power | 500w/ 750w/ 1000w/ 1500w/ 2000w/ 3000w/ 4000w/ 5000w/ 6000w/ 8000w/ 10000w/ 12000w | |

| Worktable optional | 4000*1500mm/ 4000*2000mm/ 6000*2000mm/ 6000*2500mm | |

| Tube length optional | 3000mm/ 9000mm | |

Scope of Application