Views: 21 Author: Site Editor Publish Time: 2021-12-29 Origin: Site

The ATC CNC Woodworking Machine is a advanced CNC router machine, it is a good choice for big company to produce the CNC products. Compared with ordinary CNC router machine, the ATC CNC router has an automatic tool changer, which has an independent tool Library, so the ATC CNC router can automatically change the tool through a computer program without stopping the machining process and then manually changing the tool. The Atc Spindle Cnc Router can automatically complete a series of engraving, cutting, milling, grooving, and hollowing processes. ATC CNC router greatly improves work efficiency and is an ideal choice for mass production.

This CNC engraving machine is suitable for processing a variety of plates and has a wide range of functions. It can be engraved, cut, drilled, milled and so on. The spindle is selected from the well-known Chinese brand HQD that has obtained CE certification. The 9.0KW high-power air-cooled spindle has a strong cutting ability and can easily complete the engraving and cutting work of the plate. In addition, add a 3.5KW horizontal spindle. The horizontal spindle with drills on both sides is the best choice for horizontal drilling and milling.

The CNC router adopts T-Slot&vacuum table, which can not only fix materials in different areas by gas suction, but also fix various shapes of plates with clamps, which is flexible and convenient to use. In order to completion of horizontal drilling and milling, 4 vacuum pads are specially added to facilitate the heightening of the plate to complete the side drilling work. Because the user needs to process thicker materials, we customize the Z axis height of the machine to 500mm according to this need.The ATC works to significantly increase productivity by reducing the time the CNC machine spends idle. It allows for a large number of tools to be stored locally to the machine each of which is returned automatically when its task is complete. This also makes it much simpler to change large or heavy tools that would be otherwise difficult to handle.

IGOLDENCNC ATC CNC router is equipped with a 3.0KW double-bag dust collector for customers, with an independent bracket, which is more convenient and beautiful to install. It not only ensures the cleanliness of the working environment, but also benefits the health of the staff. With Taiwan Hiwin square guide rails, it runs smoothly, with high speed and quietness, high abrasion resistance, and good load-carrying capacity.

| Description | Parameters |

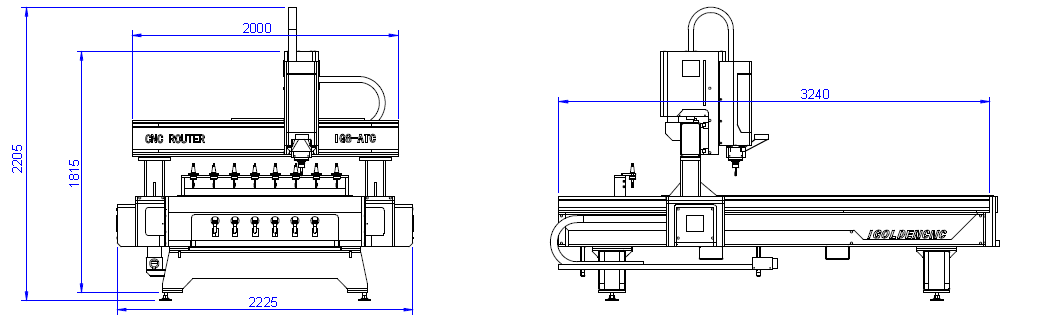

| Working area | 1300*2500*200mm |

| Spindle | ATC 9KW air cooling spindle |

| Inverter | Fuling |

| Motor | Dorna servo motor and driver 1500W and shimpo Reducer |

| Driver | Dorna servo motor and driver 1500W |

| Control System | LNC |

| Table | Vacuum and T slot table with 5.5kw cooling pump |

| Oil lubrication | Automatic lubrication |

| Limit | Omron limit |

| Transmission | XY axis helical rack Z axis Taiwan ball screw |

| Rail | X,Y,Z axis Taiwan HIWIN Square guide rail |

| Screw | Z axis TBI 3210 ball screw |

| Bed | Thick steel welded big square tube |

| Gangry | Strong frame |

| Pillars | Steel pillar |

| Cabinet | Independent cabinet |

| Voltage | 3 phase/380V |

| Dust collector | Double bags 3.0kw |

| Tool library | Automatic up and down |

| *Some specifications can be customized upon request, please contact us | |

ATC CNC Woodworking Machine Application

1. The process of automatic order removal, optimization, design, cutting, drilling, milling, troughing, automatic cutting and other processes of the cabinet are completed at one time. Four-process blanking machine, four-step blanking machine advantages, CNC blanking machine.

2. Wood door and furniture decoration industry: solid wood and composite door, cabinet door, large area plate plane carving, solid wood carving and milling, panel furniture carving, antique mahogany furniture carving, solid wood art mural carving and other industries.

3. Wooden handicraft processing: clock frames, craft photo frames, thin aluminum plate handicraft carving and carving, electrical countertops, sports equipment. Four-process blanking machine, four-step blanking machine advantages, CNC blanking machine.

4. Electronic product industry: engraving and milling of circuit boards, insulating materials, LED display screens, household appliances (color TVs, washing machines, refrigerators) shells or models.

5. Musical instrument production industry: Carving the three-dimensional curved surface and shape cutting of musical instruments, such as engraving and milling of large and violin panels and heads.

6、ATC CNC router is able to engrave exquisite patterns on the furniture and make high-end wooden furniture. ATC CNC router has the function of cutting, engraving, grooving, drilling, etc. This machine can not only process common furniture like cabinet and doors, but also can make wave boards, screens for indoor decoration.