Views: 24 Author: Site Editor Publish Time: 2021-09-09 Origin: Site

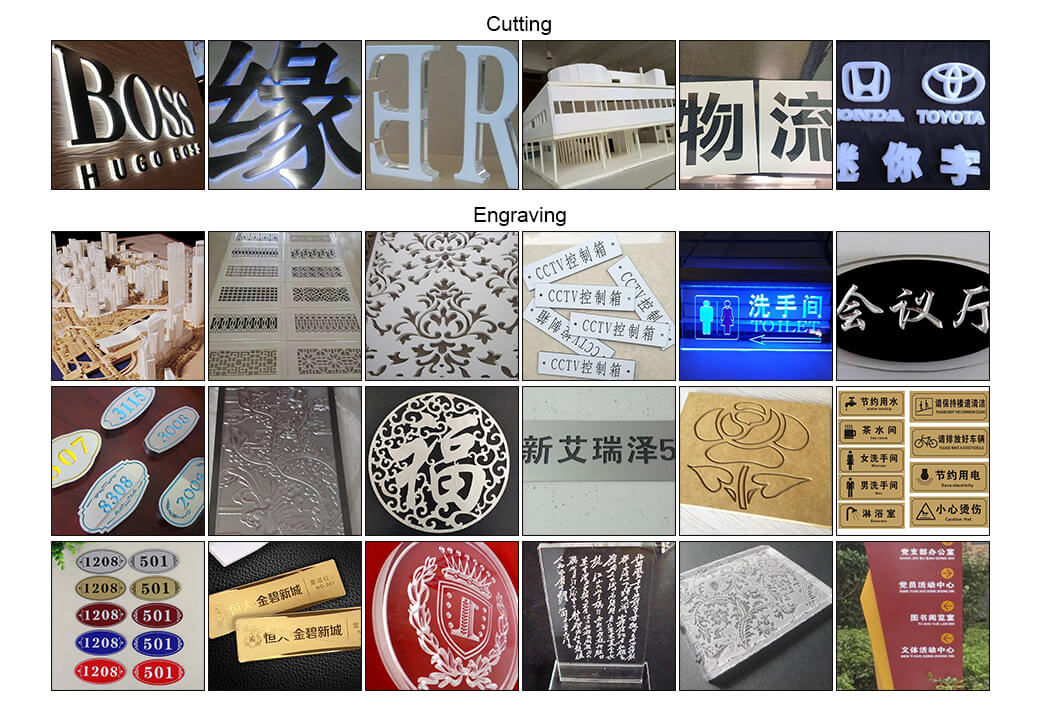

The CNC machine for acrylic mainly for cutting and engraving on MDF,Wood ,Acrylic,Aluminum and foam. Mainly used in wooden industry, furniture industry, technology research, advertising design, arts creation, and hobby purposes.

Tool Selection

There is an enormous and sometimes bewildering choice of CNC Router tooling available. There are single, twin and triple flutes, straight, compression and spiral flutes. There are even special coatings that can be applied. This makes the task extremely difficult. However, selecting the right tool for the job can make the difference between a perfectly smooth and clean cut, or something that looks like it has been hacked out with a saw.

When operating with plastics, a high-quality router bit is essential. An upward spiral, single flute geometry usually gives best results on acrylic. The upward geometry provides a smooth and consistent finish and ensures optimal chip extraction. For best cut quality, always choose a tool with the shortest flute length that will cut through your material. This helps to reduce cutter deflection and chatter.

A strong machine is a key starting point to a successful project. Ideally, you will have already purchased a suitable CNC Router. If you have not yet done so, we have some advice to get you started.

When searching for a high quality finish, there are four key components to consider during the buying process:

1. A strong, rigid base is essential. Purchasing a heavy-duty router allows you to couple a strong base with a stiff, solid gantry. A strong structure supports demanding processes, offering a robust and reliable unit while helping to minimize vibration and movement.

2. A smooth control and drive system has arguably the most important role in producing a quality outcome.

3. Helical Rack systems and servo drive motors both help to deliver a smooth drive. As a result vibration is kept to a minimum. The machine itself can cut at a higher speed, producing higher volumes without losing quality.

4. Finally, a competent vacuum hold down system is highly recommended. The vacuum hold down ensures material stays in the correct place throughout the cutting process. Even the slightest material movement can put the software program, spindle and material out of sync, invariably ruining the piece completely.

Adapting your feeds and speeds per application is absolutely essential to getting the best out of your investment. Machine settings must reflect what you are trying to achieve as each material differs in thickness, texture, and usability.

The key here is to not set your acceleration rate or feed speeds too high, but to start with a lower figure and adjust accordingly. Reducing tool acceleration consequently minimizes the risk of machine vibration, which is commonly caused by a high tool speed combined with a sudden change in the direction of the gantry.

Scope of Application

Woodworking industry: woodworking engraving machine, photo frame cutting, wave board processing, wooden door production, MDF, violin arc surface production, solid wood furniture carving, solid wood art mural carving, paint-free door carving, cabinet door, craft wood door, paint-free door, screen, auxiliary processing of computer desks and panel furniture products;

Billboard industry: large-character cutting, sign making, cutting PVC, crystal plate, acrylic, aluminium plate engraving and cutting, led / neon groove, hole-shaped literal cutting, plastic light box mold making;

It can also be used for the processing and production of various badges, department cards, architectural models, rulers, small metals, wooden molds, and reliefs.