Views: 24 Author: Site Editor Publish Time: 2022-04-29 Origin: Site

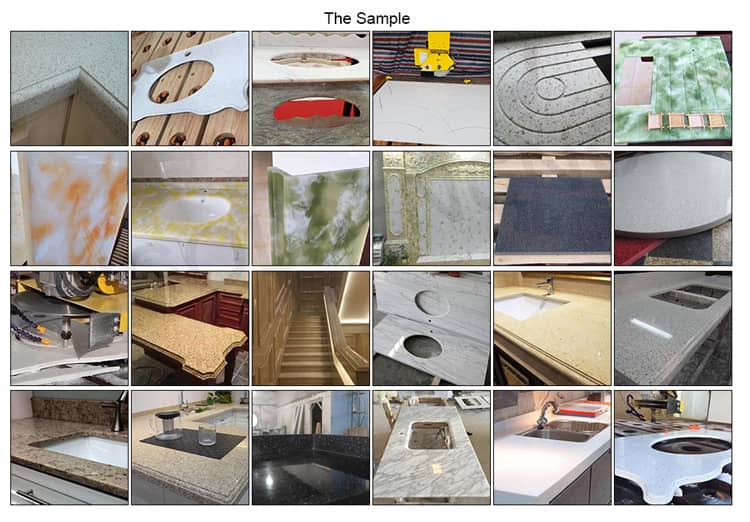

Stone Cutting Cnc Machine is designed for cabinets artificial stone, quartz stone, granite, marble, carving, cutting, polishing, drilling, engraving. Now the affordable CNC stone machine for sale at the best price.

Features of cnc machine stone cutting :

One machine with multiple functions: one CNC Stone Quartz Router machine can replace many cutting and polishing machines and we can finish all quartz processing in only one machine. In this case, we can save time and improve production.

Very Easy to operate the machine: It takes only one or two days for machine operator to understand and operate this CNC Quartz Stone Router Machine. Any operator who can understand stone drawing can run this CNC machine easily. Image we are using different machines to process quartz counter top in different steps, we need to hire many workers for running each machines. Now with 3d stone cutting machine, we need only one person to done all these work.

Good for environmental protection and health. Stone Cutting Cnc Machine adopts water dedusting and water cooling system to avoid generating a lot of dust and refusing pneumoconiosis.

High automation and low cost. CNC Stone Counter top router machine can processing some counter top products with big size such as 3 meters and even bigger size. This is impossible to finish with manual stone polishing machine. We just need to enter some parameters on the computer screen such as cutting size, grinding angle etc, then machine will finish all jobs. Because we can do all work on one machine, it save both time and cost.

High precision and high quality. This cnc machining machine belongs to 5 axis CNC Stone cutting machine, it High precision, stable quality, high productivity, improvement of working conditions and conducive to modernization of production management.

Main Configuration

5.5KW Water Cooling spindle which is special for marble engraving.

Precision high-precision helical rack, stable transmission, low noise, and large transmission torque

High-power drive motor, high power, low noise, and high precision

Schneider Electric components, stable performance, no interference

25mm square linear guide

Cast Steel gantry, thick machine body, the anti-twist structure of the beam

The working table is a T-shaped thick aluminum profile. High-hardness PVC can be used to fix various special-shaped materials with fixtures, which is flexible, convenient, and practical.

Fast processing speed, high efficiency, fine engraving without a serrated ripple, a smooth bottom surface, and a clear outline.

Buddha Sculpture of Stone Cutting Cnc Machine

Applicable materials: stone, wood, substitute wood, metal, man-made materials, etc. Uses/applications: It can be used for carving and processing complex models of root carving, various jade and stone, suitable for processing three-dimensional craft models such as statues, portraits, animals, landscapes, etc.

A stone cutting CNC machine offers numerous advantages over traditional stone cutting methods. Here are some of the key benefits:

Precision and Accuracy: Stone cutting CNC machines provide unparalleled precision and accuracy. The computer-controlled movements ensure that each cut is consistent and exact, eliminating human error and producing high-quality results. This level of precision is especially crucial when working with intricate designs or delicate stone materials.

Time Efficiency: Stone cutting CNC machines significantly reduce the time required to cut and shape stone. The automation of the cutting process allows for faster and more efficient production, enabling stone fabricators to take on larger projects and meet tight deadlines.

Versatility: Stone cutting CNC machines can work with a wide range of stone materials, including granite, marble, limestone, and more. This versatility allows for the creation of various stone products, such as countertops, sculptures, architectural elements, and decorative pieces.

Complex Designs and Intricate Details: Stone cutting CNC machines excel at cutting complex designs and intricate details in stone materials. The ability to follow precise patterns and curves allows for the creation of custom stone products with intricate designs, enhancing the aesthetics and functionality of the final piece.

Waste Reduction: Stone cutting CNC machines optimize the use of stone, minimizing waste and maximizing the yield from each piece. The ability to program the machine to cut with precision reduces the chances of errors and material loss, making it a cost-effective and environmentally friendly option.