Views: 27 Author: Site Editor Publish Time: 2021-10-09 Origin: Site

This is a Big Stone Cutting Machine with 45 degree chamfering function for slab cutting. Matching up with rotating worktable, it can cut the slab of granite, marble, quartz or other natural or artifical stone into size and polygon as you like.

This is an economical, efficient and durable stone processing machine with strong practicality.

1. First place two tracks parallel to the ground. Its width is equal to that of the cutting wheel of the cutting frame.

2. Put the frame on the parallel track, and move forward and backward to completely match the track and move freely.

3. Put the main machine of the stone cutter on the frame. The four rollers on the main machine should completely match the channel steel on the frame. Exercise freely.

4. Install the power so that the motor is firmly connected to the host through the motor tripod, and the direction of the motor axis is horizontal and perpendicular to the direction of the host.

5. Install the belt

6. Install the shield.

7. Start the motor and check that the rotation direction of the saw blade shaft is consistent with the direction indicated by the arrow on the shield.

8. Install the saw blade. Connect the water pipe.

Features of Big Stone Cutting Machine

1. Two saws, special for cutting sintered stone

2. XYZC four axis, C axis 0 to 135 degree automatic rotation, horizontal, vertical and diamond cutting.

3. PLC control system, input operating parameters on the control panel, and the cutting process is automated and programmed.

4. By infrared ray to confirm the position of the workpiece.

5. whole steel structure machine body ensuring high stability.

6. Running stability, high precision, high speed.

7. Compact and rational design, small size machine, convenient to handle and move.

Stone Cutting Machine Technical Data

| Workpiece Size | mm | 350*1000*6 |

| Z Axis Working Height | mm | 600 |

| Positioning Accuracy | mm | 0.05 |

| Re-positioning Accuracy | mm | 0.02 |

| Body Structure | Welding Body | |

| X, Y, Z Axis Structure | Linear Guide Rail, Ball Screw | |

| Max. Running Speed | mm/min | 30000 |

| Max. Working Speed | mm/min | 15000 |

| Spindle | kw | 5.5kw Water-cooling Spindle*6(6-12 Spindle Optioned) |

| Spindle RPM | rpm/min | 24000 |

| Working Voltage | V/Hz | AC 380V±10%/50-60Hz |

| Machine Weight | kg | 6300kg |

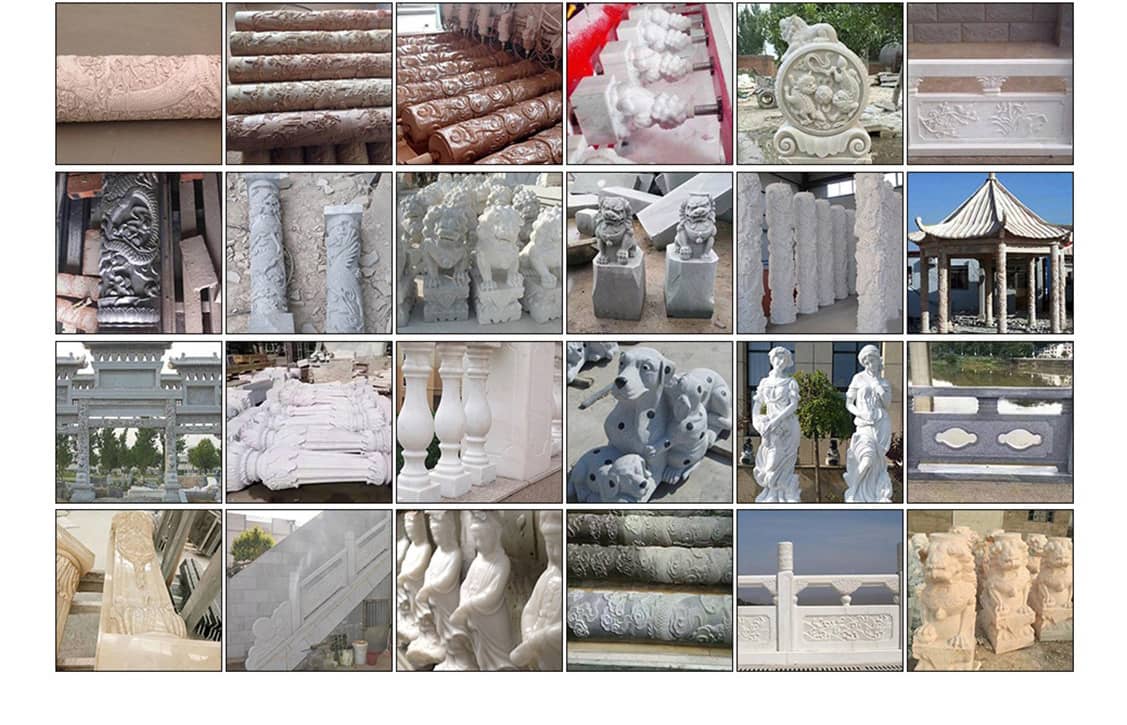

Big Stone Cutting Machine application:

Applicable Material: Acrylics, artificial stones, artificial marble, woods, bamboos, organic boards, double-color board, PVC board, aluminum, brass and other materials.

Applicable Industry: Woodworking industry, stone industry, advertising industry, artwork or decoration industry, electronica industry, mold industry and music industry etc.

Marble Granite CNC Cutting Machine Scope of Application