Views: 9 Author: Site Editor Publish Time: 2022-01-04 Origin: Site

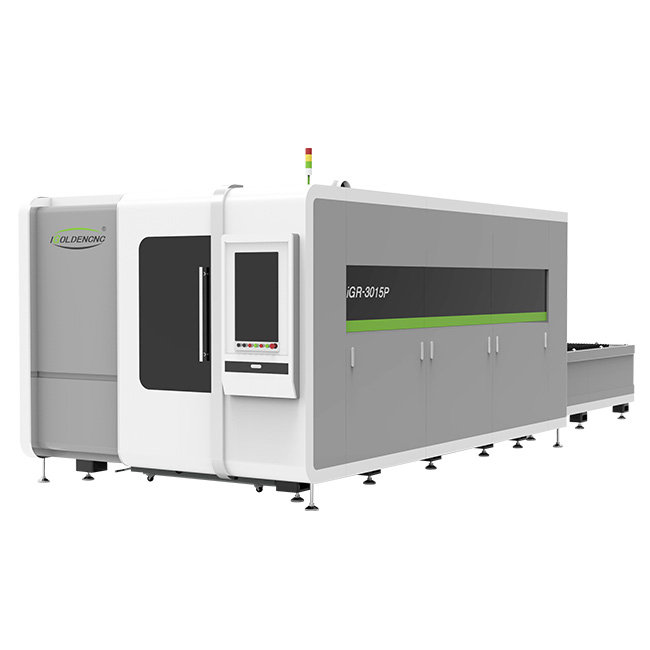

The cnc fiber laser cutting machine improves upon the PRO with a more robust frame, premium components, and increased power options (up to 1KW) for more demanding production environments. Laser cut steel, aluminum, brass, copper, titanium and more. Includes U.S.A made IPG power source, onsite installation and training, and a full 2-Year warranty.

• Speedy cutting reaches up to 25 meters per minute for carbon steel and stainless steel.

• Cut a wide range of materials efficiently up to 30mm metal: Carbon Steel, stainless steel, aluminum, brass, copper, titanium and other non-ferrous metals

• IPG laser source available in 1kw, 2kw, 3kw, 4kw, 6kw, 8kw, 10kw, 12kw, 15wk to fulfill customer’s specific needs.

• Raytools AG auto-focusing cutting head to provide reliable cutting quality, safe operation and lower post-work cost.

• Auto exchanging table with the Hydraulic lifting system can increase the productivity. Available bed sizes: 118.11" x 59.05"(3000mm x 1500 mm), 157.48" x 78.74" (4000mm x 2000 mm), 236.22" x 78.74"(6000mm x 2000 mm) or customizable sizes.

• Real-time and monitoring and playback recording can be viewed on both embedded monitor and a user-friendly APP on mobile devices.

• CCD technology, Eagle eye, facilitates ultra-fast positioning of the sheet metal edge and minimizes cutting time. It also can process punching and precut parts by utilizing the second positioning function.

• Energy-saving mode: Automatically switched to “standby” mode after being idle for 5 minutes.

• Operate the machine by the remote controller to make reacting time faster and the working environment safer.

CNC fiber laser cutting machine has the advantages of fast cutting speed, high cutting accuracy, short production cycle, non-contact processing, lower production cost, and increase production efficiency. Many metal manufacturers hope to replace traditional processing methods with laser cutting machines. But for the customer who buys fiber laser cutting machine for the first time, how to choose the right laser metal cutting machine? The following are some points to note.

Understand the metal material to be processed and choose the appropriate laser machine specifications.

The fiber laser cutting machine can cut all kinds of metal plates and tubes, and is mainly suitable for cutting metal materials such as stainless steel, carbon steel, aluminum, brass, and alloys. Before you choose a fiber laser cutting machine, you need to understand your processing materials. According to the size and length of the material, choose the worktable size of the laser machine. Choose the appropriate laser power according to the thickness of the material and your requirements for cutting speed and cutting accuracy.

Compared with other equipment, fiber laser cutting machine has the advantages of small cutting burrs, no slag inclusion, etc., which can save secondary processing and production time. Therefore, when purchasing a fiber laser cutting machine, the processing accuracy of the equipment, the moving speed during the cutting process, and whether the operation is complicated, safe, and environmentally friendly are all key factors that need to be considered.

It is also very important to examine the comprehensive strength of laser equipment manufacturers. When buying a fiber laser cutting machine. You need to understand the production scale and technical support capabilities of the laser equipment manufacturer. If you need to purchase multiple equipment at the same time, you should better go to the factory to visit.

Manufacturers with strong comprehensive strength are more assured in product quality and sales services. At the same time, you need to understand the technical team of the laser manufacturer so that when you need technical support, the engineer can help you.

Finally, choose metal cutting equipment according to your existing budget. For fiber laser cutting machines, the price will vary greatly due to different accessories and different laser power. Therefore, you need to learn more about the equipment information provided by multiple suppliers and choose the laser equipment that is more suitable for your workshop needs.

Shandong Igolden CNC Technology Co., Ltd. Established in 2012, is a professional manufacturer engaged in the research, development, production, sale and service of woodworking engraving machine, stone engraving machine, foam cutting and engraving machine, laser cutting machine, plasma cutting machine and mask making machine. We are located in Jinan, Shandong with convenient transportation access. We dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction. In recent years, our company has introduced a series of advanced equipment including Welding Machine, Bending Machine and Cutting Machine, etc. In addition, we have obtained ISO, CE, FDA certificates. Selling well in all cities and provinces around China, our products are also exported to clients in such countries and regions as Southeast Aisa, Middle East, Eourope and North America. We also welcome OEM and ODM orders. Whether selecting a current product from our catalog or seeking engineering assistance for your application, you can talk to our customer service center about your sourcing requirements. Our company adhere to "management for efficiency, survive by quality, credibility for development" business philosophy, actively improve the valuation of product quality, insist on the principle of "specialization and practical" for design of products. We pursue excellence and constant excellence, and try our best to offer excellent quality products with favorable price and perfect service system for customers.

Fiber laser cutting machine Application Field

1.Application Materials: Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

2.Application Industries: BODOR Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.