Views: 5 Author: Site Editor Publish Time: 2021-10-16 Origin: Site

CNC fiber laser cutting machine is currently the most advanced cutting technology in the world. Most metal processing uses fiber optic laser cutting machines, which are also metal processing equipment. How strengths are CNC fiber laser cutting machine to stand out among many equipments? What are the characteristics of laser fiber cutting?

The cutting quality is good: non-contact cutting, the heat-affected area of the cutting seam is small, and the cutting seam generally does not require secondary processing. The laser is less affected by the environment, can achieve high energy output in a short time, and has a small laser spot. High energy density, good cutting effect. The heat-affected area of laser cutting is very small, the cutting seam is between 0.1-0.2mm, and the cutting seam section is a regular rectangle with a beautiful shape. The cutting surface of laser cutting is smooth and burr-free, and the cut parts can be used directly without reprocessing. It can be used as the last process of sheet metal processing.

2.Fast cutting speed: The laser cutting speed is fast. The 1000 watt laser cutter can cut carbon steel plates below 2mm, and the cutting speed can reach 8 meters per minute. The deformation of the workpiece is extremely small during the processing, and no tools are needed to fix the workpiece, which saves the time of clamping the workpiece and makes the cutting speed faster.

3. A wide range of cutting materials: CNC fiber laser cutting machine can cut stainless steel, carbon steel, aluminum, copper, galvanized sheet, and other metal materials, and can also cut plastic, wood, rubber, leather, ceramics. For non-metallic materials such as paper products, the performance of laser cutting will vary due to the different absorption rates of different materials.

4. High cutting accuracy: The positioning accuracy of the laser cutting machine for metal sheet is 0.05mm, and the repeat positioning accuracy is 0.02mm.

5. Little environmental impact: The laser beam of the custom metal laser cutting machine is different from the electron beam. The laser processing is not interfered with by the electromagnetic field and does not need to create a vacuum environment.

6. Suitable for processing large workpieces: the mold manufacturing cost of large workpieces is high, and the CNC fiber laser cutting machine does not require a mold during the cutting process, saving processing costs.

7. Safety and environmental protection: The laser cutting steel sheet machine has low noise during the working process and hardly produces pollutants. It will not harm the health of the staff and will not affect the processing environment.

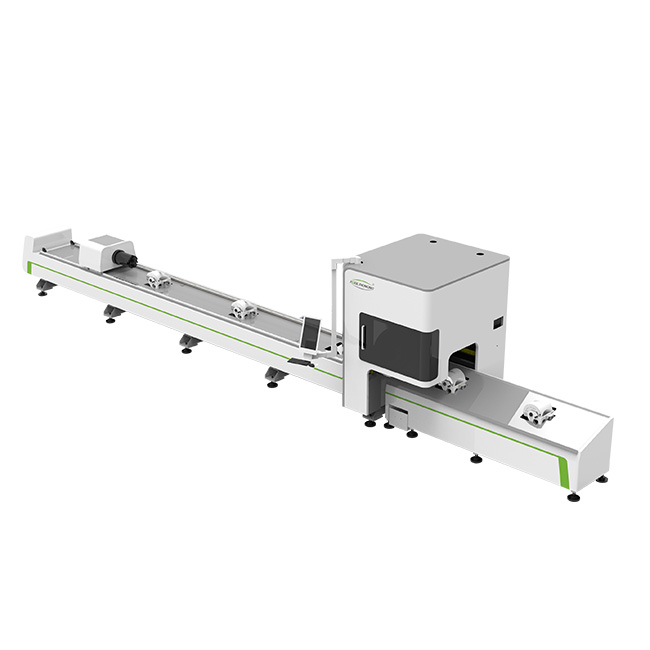

The overall structure

The main part of the machine is the most important part of the whole laser cutting machine. The cutting function and cutting precision of the laser cutting machine is realized by the host part which composed of the bed (Y axis), the beam (X-axis), Z axis, working table, air and water channel

fiber laser cutter's frame partThe bed is made of high-strength cast iron with integrally welded structure, annealed to eliminate casting stress, vibratory stress relief after roughing→ semi-finishing→ vibratory stress relief →finishing

Beam sectionThe beam part is welded with the whole high strength square tube, machining after artificial aging, to ensure the overall rigidity and strength. The processing flow is rough processing→ vibration aqing→ semi-finishing → vibration aging -finishing.

Exchangeable workstation base and workstations (optional)Workstations adopt the overall welding structure, with good strength and stabilityThe exchange table is divided into two parts, which are composed of a switching device and two movable cutting tables

Z-axis deviceThe Z-axis device is a portion that realizes the lifting movement of the cutting headThe lifting movement of the cutting head is realized by the numerical control system control the servo motor. The motor drives the ball screw to drives the Z-axis skateboard do reciprocating motion up and down.

1.Stability and reliability of light path system and control system.

2.Imported original fiber lasers,high and stable function,lifespan is over 100000 hours.

3.Higher cutting quality and efficiency ,cutting speed is up to 80m/min with appearance and beautiful cutting edge.

4.German high performance reducer,gear and rack;Japanese guide and ball screw.