| Availability: | |

|---|---|

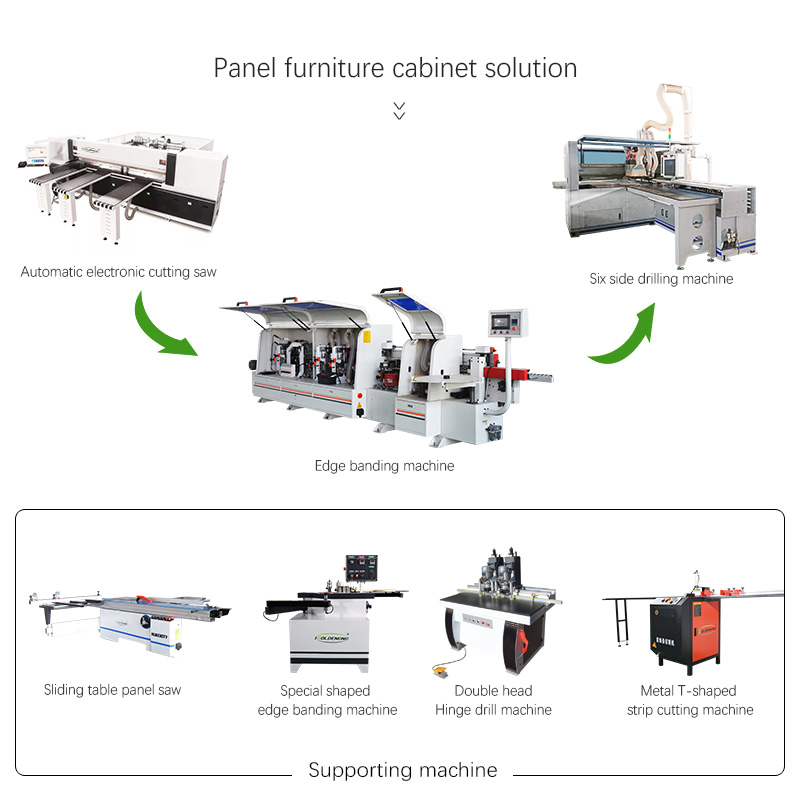

CNC Kitchen Cabinet Production Line Description:

Our CNC routers are designed for cutting an array of styles and shapes from both soft and hardwoods, chipboard, melamine, MDF, and any other type of wood you might have in mind as well as plastics.

Cabinet maker router – Igolden manufactures bespoke CNC Routers to suit professional cabinet makers. IgoldenCNC Routers have all the features essential to manufacture a range of products from flat panels, such as kitchen and commercial cabinets, store fixtures, furniture, to displays etc. Not only are our CNC router machines suitable for a range of products, with one machine you will be able to reduce your labour and waste, increase productivity and at the same time maintain quality in both product and customer service.

Kitchen Cabinet Production Line Application:

wardrobe cabinet, cupboard cabinets, computer tables, panel furniture, office furniture, wooden sound box, wooden kitchenware and other furniture. Automatic loading and unloading the plane, cutting, milling type, edge down, drilling, engraving and other ancillary processing.

Our series of CNC cabinet maker router has made the manufacturing of cabinets available to small, mid-size and large shops alike. Our CNC routing machines allow smaller manufacturers the capacity to profitably compete in their marketplace by completing customer projects with precision and cost control. Utilizing IGOLDENCNC cabinet maker Router, cabinetmakers have been able to both increase production and cut costs by reducing material handling and increasing output.

Contact us today to find the right CNC router solution for your cabinetmaking needs.

Panel Saw Machines Table Saw

Panel Saw Machines Features:

According to the input plate width, cut the required plate and quickly return to the original working state.

Cutting speed is controlled by frequency converter, which can overcome plates of different thickness and different materials.

The feeding adopts pneumatic floating bead table, and the heavy plate material is easy to change. The robot automatically feeds, has low labor intensity and high production efficiency.

Use imported Delta servo motor to eliminate artificial error and improve dimensional accuracy.

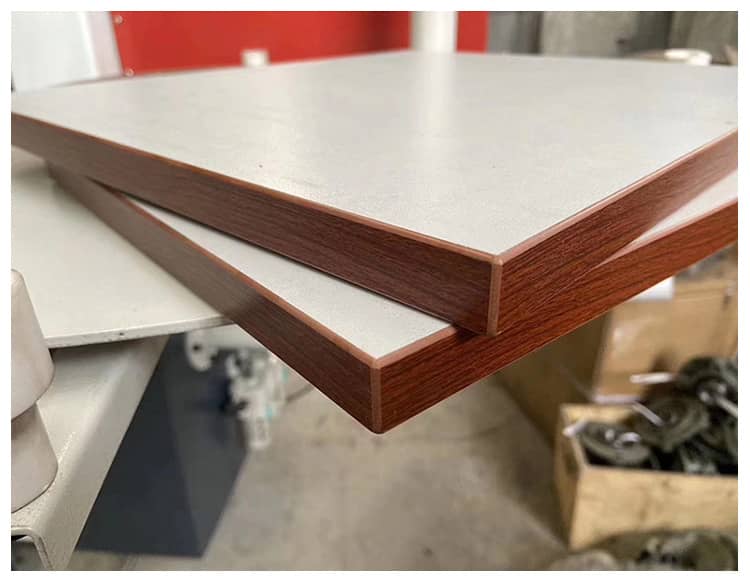

Edge Banding Machines Wood Features:

1.Full-automatic edge banding machine function include glue,head together,rough repair,refine,Scraping edgeand polishing.

2.Have good shape,reasonable layout,has sound arrester,dust collector and overload protection.

3.The main parts of the machine adopt steel plate by laser cutting,one time welded together,the body is firm and undeformed.

4.Can increase or decrease component structure according to actual demand.

1. Numerical control side drilling is an economical and practical plate type furniture horizontal hole drilling equipment,combined with CNC opening machine to form an economic plate furniture production line, the perfect substitute for the traditional push saw and drill.

2. By scanning yards, production can be completed without the need to find special drill masters. The labor cost is greatly saved. The scheme is applicable to small and medium-sized panel furniture factories.

3. Perfect combination with super star special intelligent furniture design software, truly realize intelligent production. Theprecision is high and the speed is fast.

4. The opening machine - edge banding machine - laser infrared horizontal drilling is done without interruption, so as to maximize the efficiency output.

5. The machine control interface design is humanized, simple and easy to learn, and the operator can be employed by simple training without the need of skilled workers. The machine is fast and efficient. It can help you achieve a leap in productivity.

6. Use high power air-cooled spindle, servo drive system and servo motor and other imported components to make the machine performance more stable.

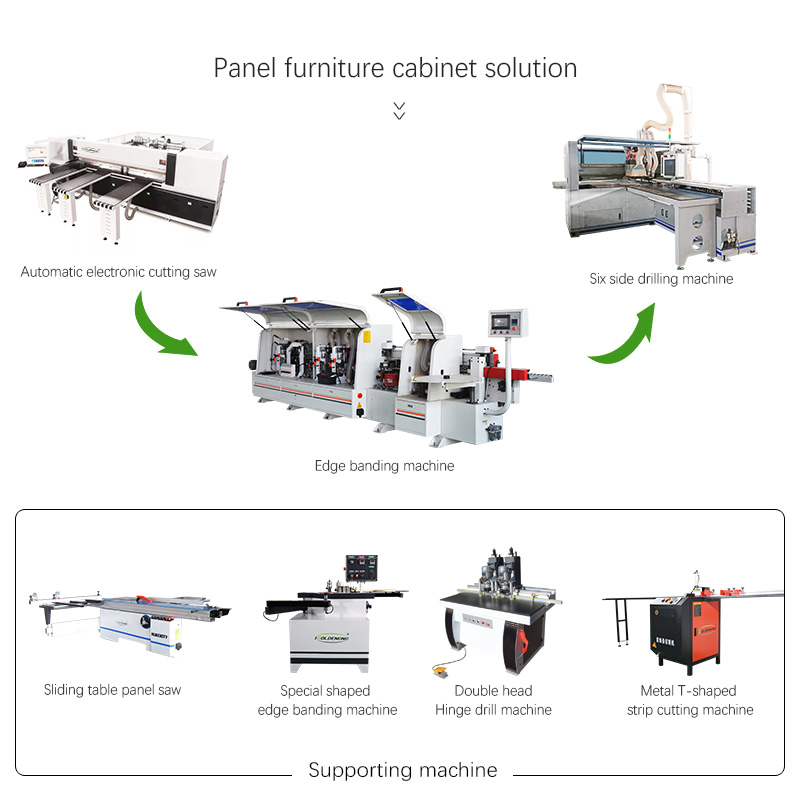

CNC Kitchen Cabinet Production Line Description:

Our CNC routers are designed for cutting an array of styles and shapes from both soft and hardwoods, chipboard, melamine, MDF, and any other type of wood you might have in mind as well as plastics.

Cabinet maker router – Igolden manufactures bespoke CNC Routers to suit professional cabinet makers. IgoldenCNC Routers have all the features essential to manufacture a range of products from flat panels, such as kitchen and commercial cabinets, store fixtures, furniture, to displays etc. Not only are our CNC router machines suitable for a range of products, with one machine you will be able to reduce your labour and waste, increase productivity and at the same time maintain quality in both product and customer service.

Kitchen Cabinet Production Line Application:

wardrobe cabinet, cupboard cabinets, computer tables, panel furniture, office furniture, wooden sound box, wooden kitchenware and other furniture. Automatic loading and unloading the plane, cutting, milling type, edge down, drilling, engraving and other ancillary processing.

Our series of CNC cabinet maker router has made the manufacturing of cabinets available to small, mid-size and large shops alike. Our CNC routing machines allow smaller manufacturers the capacity to profitably compete in their marketplace by completing customer projects with precision and cost control. Utilizing IGOLDENCNC cabinet maker Router, cabinetmakers have been able to both increase production and cut costs by reducing material handling and increasing output.

Contact us today to find the right CNC router solution for your cabinetmaking needs.

Panel Saw Machines Table Saw

Panel Saw Machines Features:

According to the input plate width, cut the required plate and quickly return to the original working state.

Cutting speed is controlled by frequency converter, which can overcome plates of different thickness and different materials.

The feeding adopts pneumatic floating bead table, and the heavy plate material is easy to change. The robot automatically feeds, has low labor intensity and high production efficiency.

Use imported Delta servo motor to eliminate artificial error and improve dimensional accuracy.

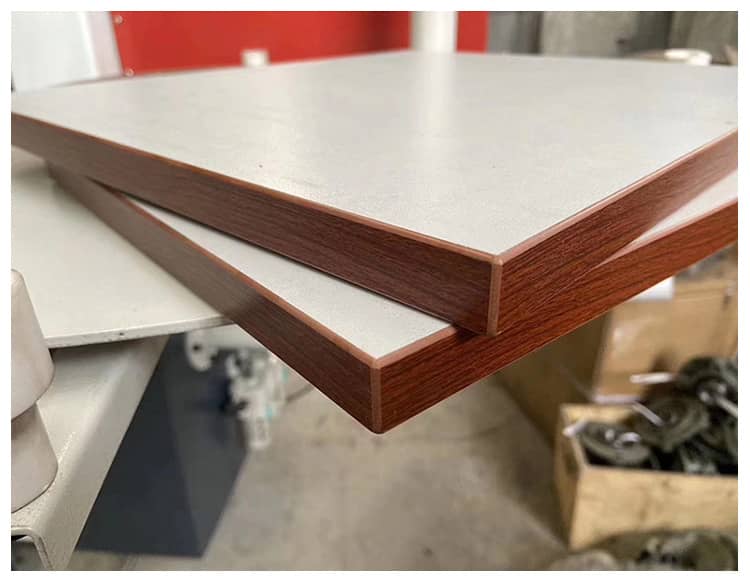

Edge Banding Machines Wood Features:

1.Full-automatic edge banding machine function include glue,head together,rough repair,refine,Scraping edgeand polishing.

2.Have good shape,reasonable layout,has sound arrester,dust collector and overload protection.

3.The main parts of the machine adopt steel plate by laser cutting,one time welded together,the body is firm and undeformed.

4.Can increase or decrease component structure according to actual demand.

1. Numerical control side drilling is an economical and practical plate type furniture horizontal hole drilling equipment,combined with CNC opening machine to form an economic plate furniture production line, the perfect substitute for the traditional push saw and drill.

2. By scanning yards, production can be completed without the need to find special drill masters. The labor cost is greatly saved. The scheme is applicable to small and medium-sized panel furniture factories.

3. Perfect combination with super star special intelligent furniture design software, truly realize intelligent production. Theprecision is high and the speed is fast.

4. The opening machine - edge banding machine - laser infrared horizontal drilling is done without interruption, so as to maximize the efficiency output.

5. The machine control interface design is humanized, simple and easy to learn, and the operator can be employed by simple training without the need of skilled workers. The machine is fast and efficient. It can help you achieve a leap in productivity.

6. Use high power air-cooled spindle, servo drive system and servo motor and other imported components to make the machine performance more stable.