| Availability: | |

|---|---|

What Is An Edge Banding Machine?

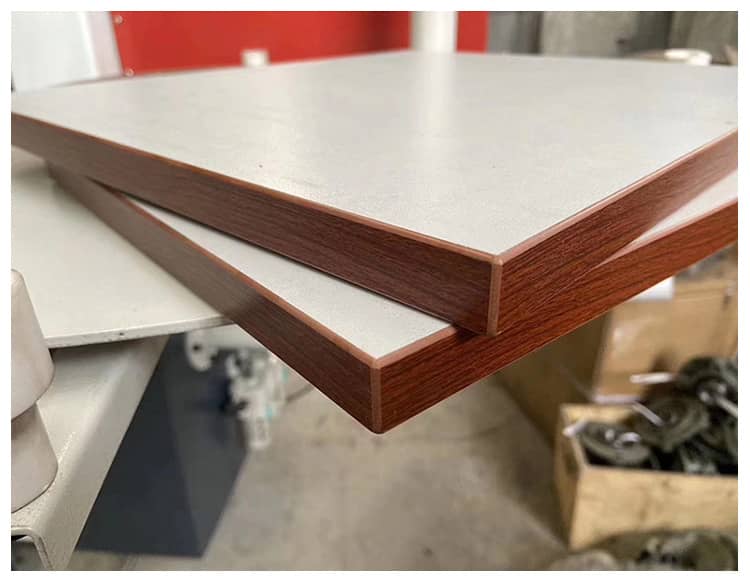

The edge banding machine is a kind of woodworking machinery and an important processing flow of furniture production line. It is used to repair excess edge banding material above and below the edge band of the plate.This machine is suitable for linear edge banding and edge banding materials of solid wood board, fiberboard, particle board and other plate workpieces.

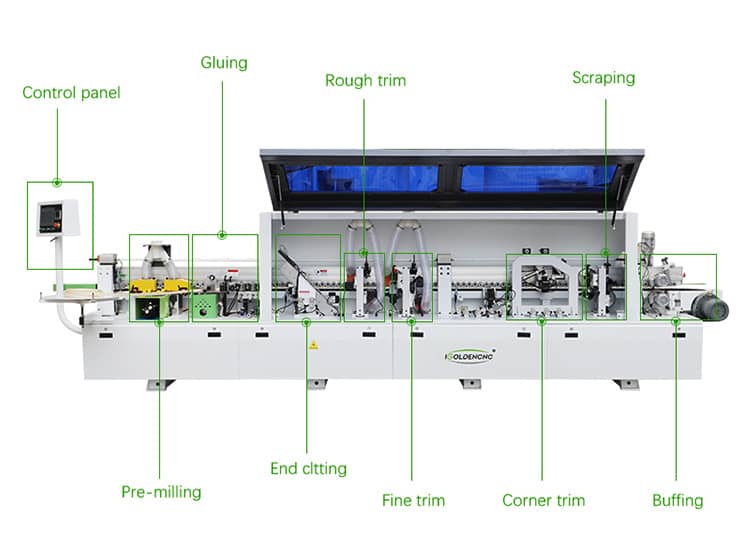

Edge Banding Machines Wood Features:

Pre-milling: Double milling cutters are used to modify the ripple marks, burrs or non-vertical phenomenon caused by the panel saw processing to achieve better edge sealing effect and to make the edge band and the board more tightly fit, better integrity and aesthetics.

Adhesive edge banding: Adopting a special structure, evenly apply adhesive on both sides of the edge banding plate and edge banding material to ensure a stronger adhesion.

Head-to-head: through precise linear guide rail movement, adopts automatic tracking of the mold and high-frequency high-speed motor fast cutting structure to ensure the cut surface is smooth and smooth.

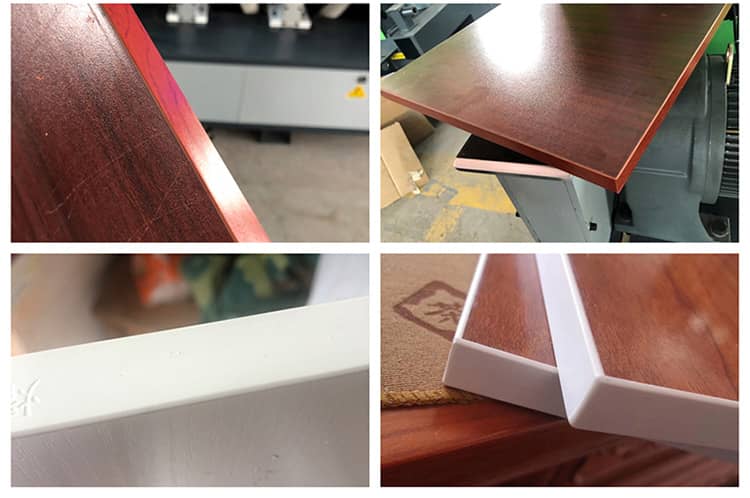

Finishing: Both the profile automatic tracking and high-frequency high-speed motor structure are used to ensure the smoothness of the upper and lower parts of the trimmed board. It is used to repair excess edge banding material above and below the edge band of the plate. The finishing knife is an R-shaped knife. It is mainly used for PVC and acrylic edge banding for panel furniture. Edge banding with thickness of 0.8 mm or more is preferred.

Scraping: Used to eliminate the ripple marks caused by the non-linear motion of the trimming process, so that the upper and lower parts of the board are smoother and cleaner.

Polishing: Clean the processed sheet with a cotton polishing wheel, and make the edge sealing end surface smoother by polishing.

Slotting: It is used for direct slotting of wardrobe side panels, bottom plates, etc., reducing the process of panel sawing, and it is more convenient and fast. It can also be used for slotting of aluminum edging of door panels.

Parameter Of Woodworking Edge Bander Machines for sale:

| Function | Pre-milling、Gluing、 End cltting、Rough trim、 Fine trim、Corner trim、 Scraping、Buffing |

| Sheet thickness | 10-60mm |

| Edge material width | 15-55mm |

| Conveyor belt power | 2.2kw |

| Feeding speed | 15~22m/min |

| Total power | 16.6kw |

| Voltage | 380v |

| Dimensions | 6200*900*1600 mm |

| Package dimensions | 5900*800*1600mm |

| Weight | 1800kg |

| Control System | Delta PLC |

Wood Edge Banding Machines Details:

TAIDA PLC control system

The independent LCD screen has a touch screen speed control function, and you can see the operation process of the machine more clearly, real-time monitoring, real-time adjustment, and more precise.

Pre-milling

When the edge-sealing surface of the plate is not flat, it can be milled first and then glued and pressed.

Gluing

Non-sticky pot, uniform sol, cylinder control pressure roller, better tape effect.

End cltting

Through the structure of automatic profiling and high-frequency high-speed motor, the redundant edge bands before and after are cut off to ensure a smooth and smooth section.

Rough trim:The rough trimming knife is a flat knife, which is used to trim the excess edge banding material on the upper and lower parts of the processed sheet edge band, so that the upper and lower parts of the trimmed sheet are smooth and smooth.

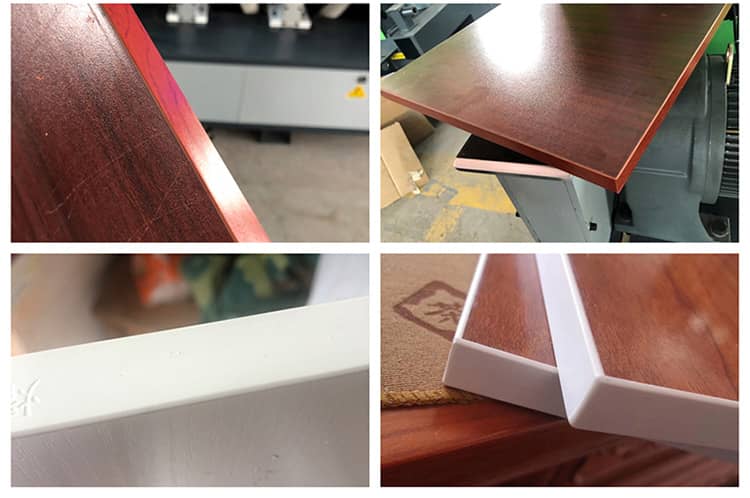

Fine trim:The finishing knife is an oblique repair, used to repair the excess edge banding material after rough repair on the upper and lower parts of the processed sheet edge band, and at the same time, make the natural transition between the sheet material and the edge band in an arc shape.

Corner trim

The contour is trimmed, and the chamfering effect is repaired, and the edge banding effect is more round and smooth.

Scraping: It is used to eliminate the ripple marks (cut marks left by the trimming knife and the finishing fillet) caused by the non-linear motion cutting process of the trimming.

Buffing: Use a cotton polishing wheel to clean the polished plate to remove excess glue and make it smoother.

Pneumatic knife adjustment

Horizontal slotting device

Vertical slotting device

Can be customized according to customer needs, please consult customer service for details.

Few Tips About Using Woodworking Machinery Edge Banding Machines:

To make the door panels, especially the acrylic door panels, the most basic functions of an edgebanding machine is rough repair, tracking pre-milling, also front and rear cleaning must be added, so that the products have high-quality surface details, to make more high-level products.

Regarding the cleaning before and after, it is actually the glue removal device, the plate which has not been treated with the glue remover, and the plate which has been treated with the glue remover. The results are really different; especially the acrylic door panel and the cabinet edge seal. So don't remove these steps if you have sufficient funds.

The most useless functions of an automatic edge banding machine are: flat scraping and pneumatic adjusting knife. Some people want to have an edgebanding machine without the need of manual adjustment of cutting tools, only by pneumatic tuning knife or automatic knife adjustment, this kind of machine doesn’t exist, you still have to adjust those cutting tools manually for the best performance.

Product Details:

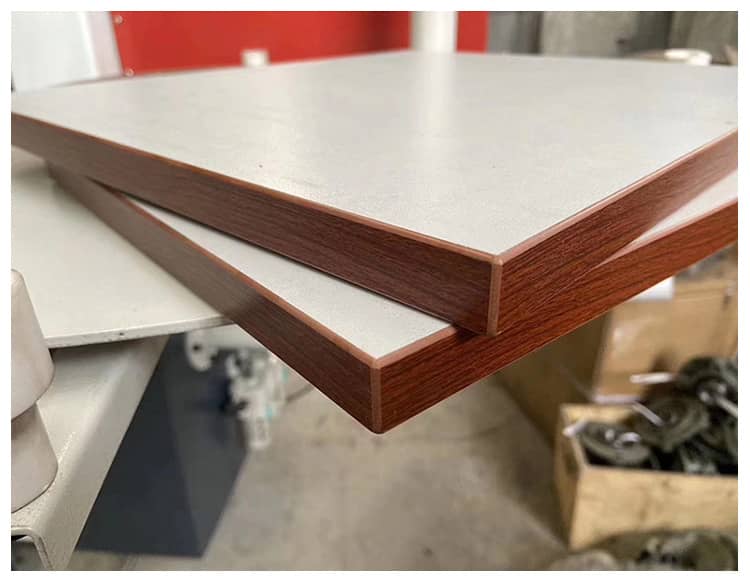

Wood Edge Banding Machines Application:

This machine is suitable for linear edge banding and edge banding materials of solid wood board, fiberboard, particle board and other plate workpieces.

Available solid wood strips, pvc, melamine, veneer strips, etc.

What Is An Edge Banding Machine?

The edge banding machine is a kind of woodworking machinery and an important processing flow of furniture production line. It is used to repair excess edge banding material above and below the edge band of the plate.This machine is suitable for linear edge banding and edge banding materials of solid wood board, fiberboard, particle board and other plate workpieces.

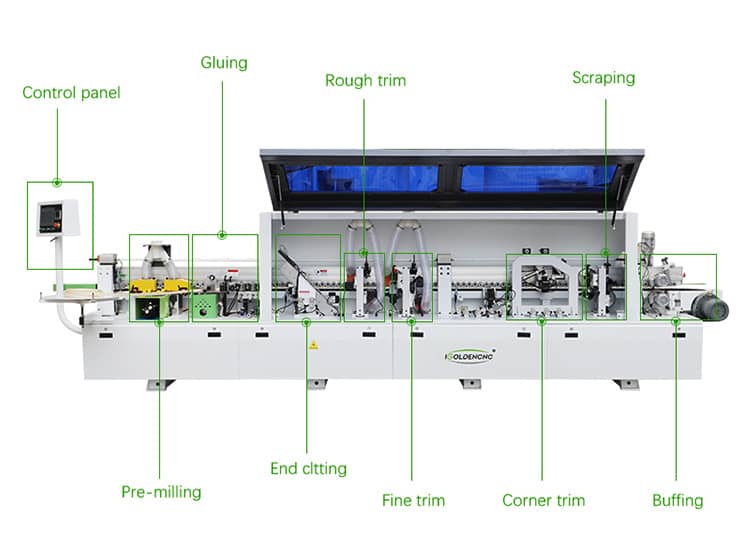

Edge Banding Machines Wood Features:

Pre-milling: Double milling cutters are used to modify the ripple marks, burrs or non-vertical phenomenon caused by the panel saw processing to achieve better edge sealing effect and to make the edge band and the board more tightly fit, better integrity and aesthetics.

Adhesive edge banding: Adopting a special structure, evenly apply adhesive on both sides of the edge banding plate and edge banding material to ensure a stronger adhesion.

Head-to-head: through precise linear guide rail movement, adopts automatic tracking of the mold and high-frequency high-speed motor fast cutting structure to ensure the cut surface is smooth and smooth.

Finishing: Both the profile automatic tracking and high-frequency high-speed motor structure are used to ensure the smoothness of the upper and lower parts of the trimmed board. It is used to repair excess edge banding material above and below the edge band of the plate. The finishing knife is an R-shaped knife. It is mainly used for PVC and acrylic edge banding for panel furniture. Edge banding with thickness of 0.8 mm or more is preferred.

Scraping: Used to eliminate the ripple marks caused by the non-linear motion of the trimming process, so that the upper and lower parts of the board are smoother and cleaner.

Polishing: Clean the processed sheet with a cotton polishing wheel, and make the edge sealing end surface smoother by polishing.

Slotting: It is used for direct slotting of wardrobe side panels, bottom plates, etc., reducing the process of panel sawing, and it is more convenient and fast. It can also be used for slotting of aluminum edging of door panels.

Parameter Of Woodworking Edge Bander Machines for sale:

| Function | Pre-milling、Gluing、 End cltting、Rough trim、 Fine trim、Corner trim、 Scraping、Buffing |

| Sheet thickness | 10-60mm |

| Edge material width | 15-55mm |

| Conveyor belt power | 2.2kw |

| Feeding speed | 15~22m/min |

| Total power | 16.6kw |

| Voltage | 380v |

| Dimensions | 6200*900*1600 mm |

| Package dimensions | 5900*800*1600mm |

| Weight | 1800kg |

| Control System | Delta PLC |

Wood Edge Banding Machines Details:

TAIDA PLC control system

The independent LCD screen has a touch screen speed control function, and you can see the operation process of the machine more clearly, real-time monitoring, real-time adjustment, and more precise.

Pre-milling

When the edge-sealing surface of the plate is not flat, it can be milled first and then glued and pressed.

Gluing

Non-sticky pot, uniform sol, cylinder control pressure roller, better tape effect.

End cltting

Through the structure of automatic profiling and high-frequency high-speed motor, the redundant edge bands before and after are cut off to ensure a smooth and smooth section.

Rough trim:The rough trimming knife is a flat knife, which is used to trim the excess edge banding material on the upper and lower parts of the processed sheet edge band, so that the upper and lower parts of the trimmed sheet are smooth and smooth.

Fine trim:The finishing knife is an oblique repair, used to repair the excess edge banding material after rough repair on the upper and lower parts of the processed sheet edge band, and at the same time, make the natural transition between the sheet material and the edge band in an arc shape.

Corner trim

The contour is trimmed, and the chamfering effect is repaired, and the edge banding effect is more round and smooth.

Scraping: It is used to eliminate the ripple marks (cut marks left by the trimming knife and the finishing fillet) caused by the non-linear motion cutting process of the trimming.

Buffing: Use a cotton polishing wheel to clean the polished plate to remove excess glue and make it smoother.

Pneumatic knife adjustment

Horizontal slotting device

Vertical slotting device

Can be customized according to customer needs, please consult customer service for details.

Few Tips About Using Woodworking Machinery Edge Banding Machines:

To make the door panels, especially the acrylic door panels, the most basic functions of an edgebanding machine is rough repair, tracking pre-milling, also front and rear cleaning must be added, so that the products have high-quality surface details, to make more high-level products.

Regarding the cleaning before and after, it is actually the glue removal device, the plate which has not been treated with the glue remover, and the plate which has been treated with the glue remover. The results are really different; especially the acrylic door panel and the cabinet edge seal. So don't remove these steps if you have sufficient funds.

The most useless functions of an automatic edge banding machine are: flat scraping and pneumatic adjusting knife. Some people want to have an edgebanding machine without the need of manual adjustment of cutting tools, only by pneumatic tuning knife or automatic knife adjustment, this kind of machine doesn’t exist, you still have to adjust those cutting tools manually for the best performance.

Product Details:

Wood Edge Banding Machines Application:

This machine is suitable for linear edge banding and edge banding materials of solid wood board, fiberboard, particle board and other plate workpieces.

Available solid wood strips, pvc, melamine, veneer strips, etc.

content is empty!