Views: 6 Author: Site Editor Publish Time: 2022-06-10 Origin: Site

CNC Plasma Cutting Machine is a processing method that utilizes the heat of high temperature plasmas to melt (and evaporate) the metal part of the workpiece incision, and to remove the molten metal by the momentum of the high speed plasma. Cnc Plasma Cutting Machine Metal (plasma Cutting machine) is a machine that uses plasma cutting technology to process metal materials. Plasma cutting is a processing method that utilizes the heat of high temperature plasmas to melt (and evaporate) the metal part of the workpiece incision, and to remove the molten metal by the momentum of the high speed plasma.

1. Automatic and semi-automatic cutting double mode selection

2. Digital Precision control cutting length

3. Easy to operate. Plasma Cutting Machine

Plasma cutting machines are widely used in automobiles, locomotives, pressure vessels, chemical machinery, nuclear industry, general machinery, engineering machinery, steel structures, ships, and other industries. There are many influencing factors of plasma cutting, including cutting parameters, working gas type and purity, operator's technical ability, and understanding of the equipment. This article discusses several methods that can improve the surface quality and production efficiency of plasma cutting products from cutting program settings and discharging.

During the plasma cutting process, an electrical arc is created when compressed gas (oxygen, air, or inert) is blown through a nozzle at a high speed toward a workpiece. The electrical arc causes the gas to become ionized, turning it into a channel of plasma. The electricity from the torch then travels down the channel of plasma to the workpiece, creating a spark that melts and blows away the molten material simultaneously to produce a cut.

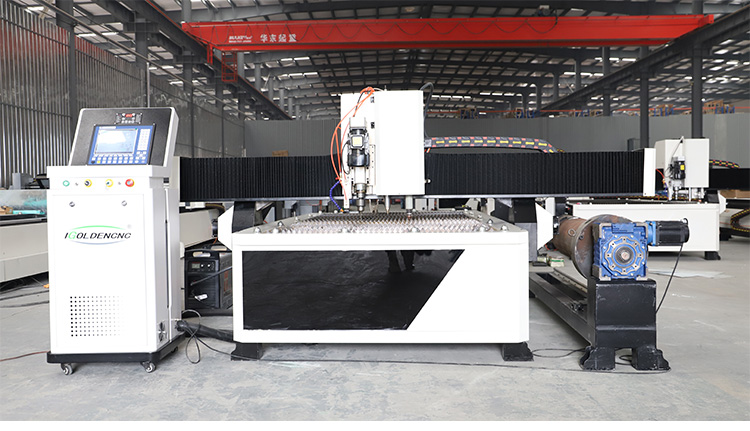

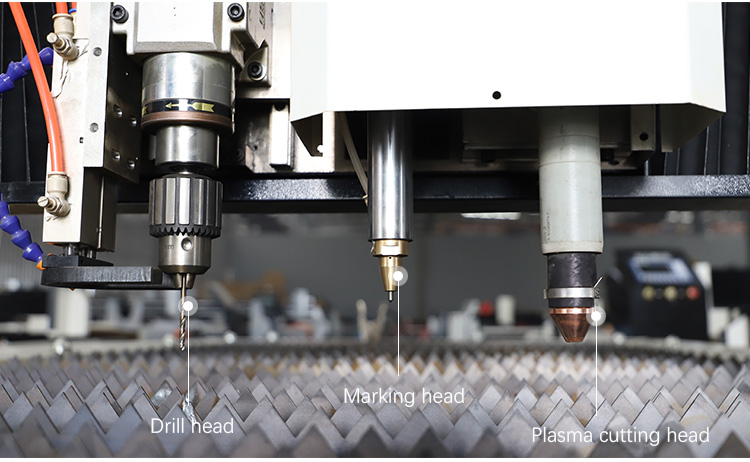

CNC plasma cutting equipment is generally summed up in three parts: Part machine, CNC and software components. The whole machine from the rail, rack, rack and pinion, speed reducer, servo motor, gas systems, cutting nozzle, dust and other cooling system components; Second, computers, power systems, servo motion control system as the core of a full set electrical systems hardware; computer software, compared with the third part, the following proposed classification profile.

2.1 Plasma arc cutting mode and power plasma arc cutting way to have the traditional high frequency high voltage mode and new non-high-frequency manner, many domestic companies are still using high-frequency high-handed way, foreign technology and other representatives of the US Treasure some domestic companies and new technology companies, the use of non-high-frequency arc technology. The type of power is usually enhanced magnetic flux leakage transformer power thyristor rectifier power supplies, power inverters and chopper power four. More generic Treasure MAX200 is a constant, providing continuously adjustable current 40-200A secondary conversion chopper power supply, these brands are currently more professional and sophisticated technology in the production and performance, there are more and more domestic products into the market competition. 3KV high-voltage high-frequency arc required to produce more high-voltage and high-frequency oscillation 150-200KHZ between the workpiece and the electrode, the breakdown of neutral gas medium to form an arc, the circuit is divided into short-circuiting and non-short-circuit type, this arc method It has a high success rate of arc, but electromagnetic interference caused by more serious, can not be used in CNC automatic cutting and electromagnetic interference demanding applications. Non-contact ignition frequency arc also known, requires direct contact with the electrode and nozzle gas pressure against the short circuit and ignite a small arc without high frequency oscillator inside the product, eliminating the high-frequency electromagnetic interference generated by high voltage discharge, reduced the harm to human body. This type of arcing electrode arc highly controlled manner to put forward higher requirements, the general set up a special arc voltage height control system.

2.2 servo control system

CNC cutting machine is a kind of numerical control technology and precision machinery closely integrated mechatronic products, technical performance has been far beyond the contour cutting, semi-automatic car like primary products, adapt cut any complex graphics. According to the size of the processing, mechanical structure may be in the form of gantry, cantilever, desktop portable CNC cutting machine, the choice of plasma or flame cutting head, as well as more specialized NC intersection Cutting, robot cutting machine, laser cutting machines. In medium-sized gantry, cantilever, for example, CNC plasma cutting machine is essentially a proprietary multi-axis cutting CNC servo system, computer control center, in the direction of two-axis cutting head above graphical motion control, in order to achieve cutting processing purposes.

2.3 arc voltage height control

Mentioned above, CNC plasma cutting of arc, arc voltage control demanding manufacturers use more specialized arc voltage height control to achieve this requirement. Plasma arc voltage height control principle is to use the basic plasma power constant current characteristic, plasma arc cutting by detecting the change in voltage to measure plasma cutting torch height change process to achieve a high degree of control over the cutting torch. Usually has several basic functions, the initial automatic positioning, power boost function perforated and broken arc torch collision, given the actual arc voltage display monitor, manual and automatic operation. Treasure products are high-performance self-supporting height control, should be mentioned, many of the domestic use of the product, performance has fully meet the engineering requirements, import substitution is very common use.

2.4 industrial computer programming and automatic nesting software

CNC plasma cutting system control center, is a set of industrial computer as the core, monitor, keyboard, integrated visual programming graphics cutting controller. In addition to the system it is usually equipped with Windows operating systems, CNC control system, but also need to install special automatic nesting software programming. A good horse with a good saddle, with corresponding with CAD / CAM programming software features drawing, editing and importing cutting pattern to be able to easily implement the entire system will be cut even more powerful, convenient, smart and reliably perform complex processing functions. Development Site software company authorized FastCAM automatic nesting software programming, the industry is currently very popular for a two-dimensional drawing cutting CNC programming software system, compared with the general traditional CAD software, not only can the usual CAD FastCAM graphing software to facilitate entry machine, cutting into the software, can also be used to clear the compression fitting and other optimization methods, to complete the cleaning DXT / DWG file extra points overlapping body compression curve fitting small entities, automatic recognition transition circle automatic common edge, by the side of the bridge, and so some of the details connected smart features that make it a higher intelligence and interactivity, and improve cutting quality assurance, which is one of the software's core technologies, especially FastCAM nesting optimization techniques, can effectively improve the utilization rate of steel nesting effectively save steel, improve processing efficiency.

The results experienced with a CNC plasma tool as compared to metal-against-metal cutting are undeniably far superior. The plasma cut will produce no chips and achieves a consistent edge, with limited error as long as the cut is properly programmed.

Industrial Applications

Plasma cutting with different working gases can cut various metals that are difficult to cut by oxygen cutting, especially for non-ferrous metals (stainless steel, aluminum, copper, titanium, nickel) the cutting effect is better.The main advantage is that when cutting metals of small thickness, plasma cutting speed is fast, especially in cutting ordinary carbon steel sheet, the speed can be 5-6 times faster than the oxygen cutting method.The cutting surface is smooth and clean, with little thermal deformation and less heat-affected zone.Plasma cutting machine is widely used in various industries such as automobile, locomotive, pressure vessel, chemical machinery, nuclear industry, general machinery, engineering machinery, steel structure, ships, etc.

Best Cnc Plasma Cutting Machine Supplier:

Our company adheres to the Market-Oriented business principles, and implements the business philosophy of "Quality First and Customer First". We have set up more than 20 sale and service departments around China which can offer our customers the services of design, fixing, training, maintenance and so on. Besides sale in China, our products exports around the world including the Middle East, Africa, Europe and the USA.