| Availability: | |

|---|---|

CNC Plasma Cutting Machine Video:

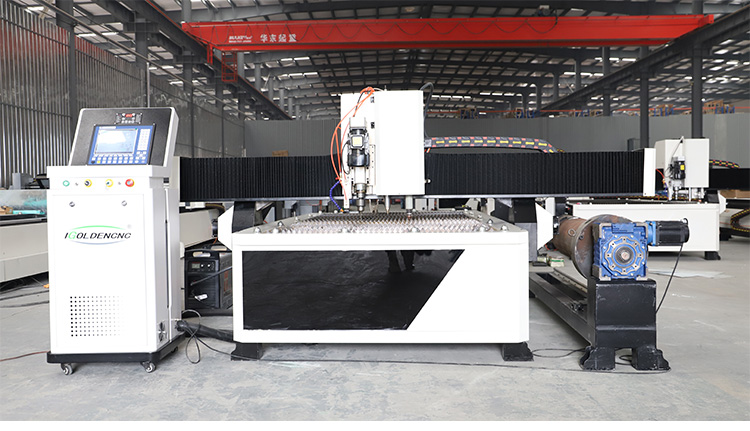

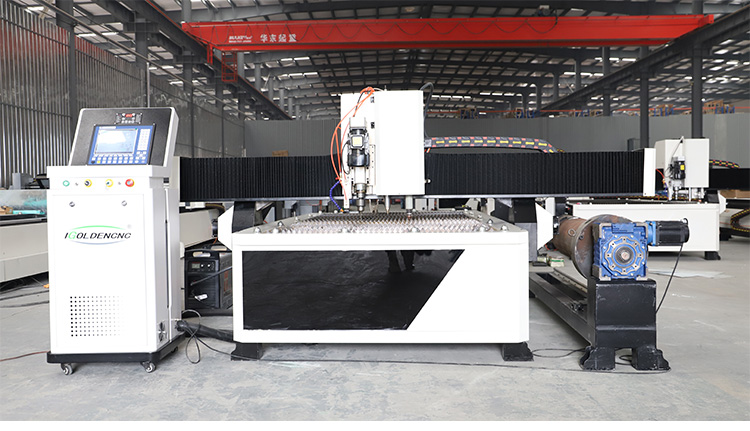

CNC Plasma Sheet Metal Cutting Machine Description:

A CNC plasma sheet metal cutting machine uses a plasma cutter to cut thin to thick metals along a multi-axis grid. The CNC method provides an advantage over handheld plasma cutting tools due to the cut being programmed and controlled by a computer instead of human motion.

.

.

Automatic Plasma Cutting Machine Parameters:

| Working area | 1300x2500mm (1500*3000/2000*3000/2000*6000mm) |

| Torch height controller | With |

| Working table | Saw tooth table |

| Plasma power supply | Hypertherm 125A (Hypertherm 65/85/200A) |

| Cooling system | Air cooling |

| Control system | F2300A control system |

| Flies transfer | USB interface |

| Transmission | X,Y-helical rack pinion, Z ball screw |

| Guide rail | Hiwin guide rail |

| Drive system | Japan servo motor and drivers |

| Arc | Untouched Arc Striking |

| Traveling speed | 0-40000mm/min |

| Working speed | According to the cutting thickness |

| Working voltage | Single phase 220V and 3 phase 380V/50HZ |

| Software | Fastcam |

| Rotary axis | With |

| Drilling head | With |

| Marking head | With |

Plasma Sheet Cutting Machine Details:

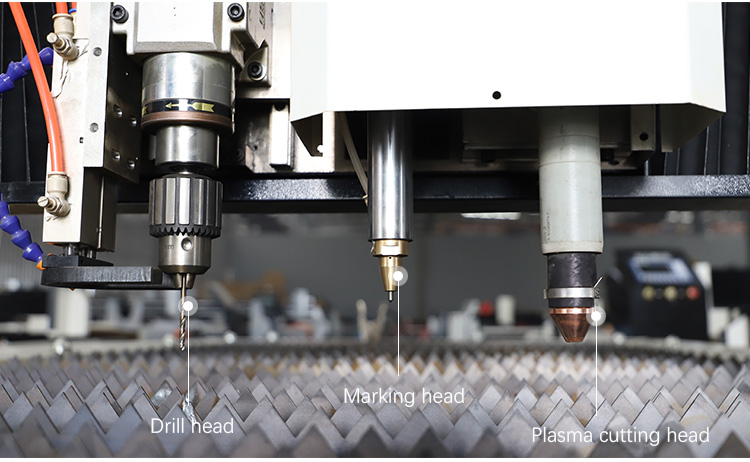

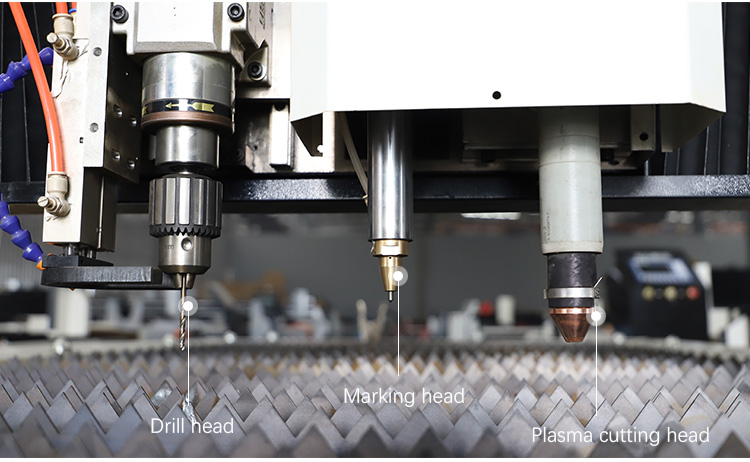

Multifunctional plasma cutting machine,with drill head and marking head, For multiple purposes

Rotary axis cutting

Saw tooth working table

F2300A control system

Hypertherm 125A (Optional:Hypertherm 65/85/200A)

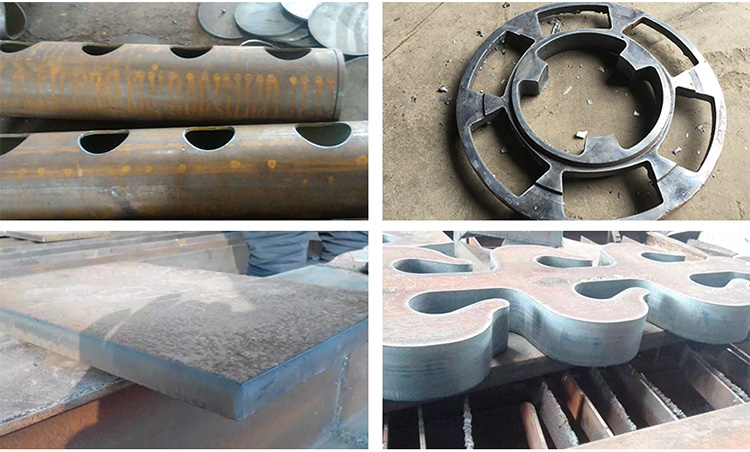

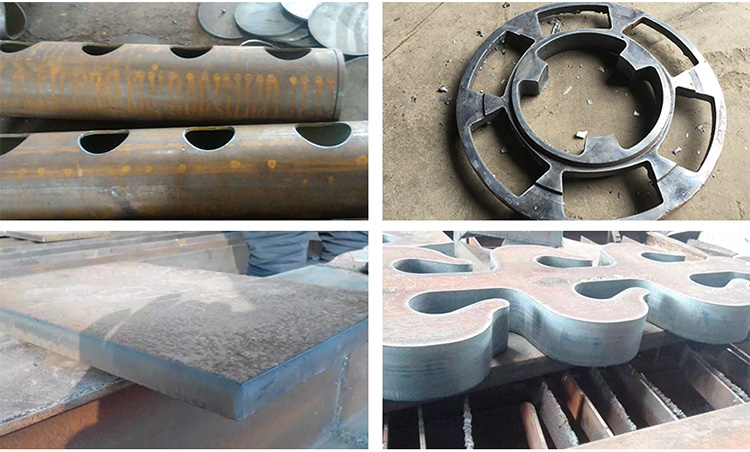

Metal Plasma Cutting Machine Processing Samples:

CNC plasma machine uses a plasma cutter to cut thin to thick metals along a multi-axis grid. The CNC method provides an advantage over handheld plasma cutting tools due to the cut being programmed and controlled by a computer instead of human motion. CNC plasma is where high speed and precision meet low cost – among a vast array of additional benefits.

Plasma cutting is a high-tech cutting method that uses an ionised, focused jet of gas to slice through thin sheet metal. An internal, high-voltage electrode in the cutter rapidly heats a compound gas mixture to over 20,000 centigrade when switched on. Shielding gas is used as a propellant and barrier to focus and move the induced plasma from the ionisation chamber. The ionised, superheated, concentrated beam of plasma then melts and blasts any metal it touches. A clean, sealed cut is made each time.

1. VERSATILITY

One of the biggest benefits of CNC plasma cutting is that it is an extremely effective option for cutting both thin and thick metals, such as steel, stainless steel, brass, copper, and aluminum. CNC plasma cutting machines can also be used to help improve production speeds and reduce costs for a variety of different industries.

2. FAST CUTS

Since CNC plasma cutters are specifically designed to complete large-scale projects in a fraction of the time it would take to complete using a hand tool, CNC plasma cutting can help reduce the overall time spent on a project, while also producing cleaner cuts. CNC plasma cutting machines can be programmed to cut a wide range of diverse shapes, making it a much more efficient means of completing cuts on short notice.

3. PRECISION

CNC plasma cutters are operated using a computer program that is incredibly precise. Once a cut has been programmed into the machine, the plasma torch will follow the exact path created by the computer, providing a reliable and consistent cut every single time.

4. EASE OF USE

While most metal cutters require a lot of training and experience to use extremely well, CNC plasma cutters are easier to use and do not require as much training to handle properly. This means that CNC plasma cutting machines can help minimize the overhead costs and downtime associated with training new employees.

5. INCREASED SAFETY

Since CNC plasma cutters are computer operated, they are much safer to use than other metal cutters. All cuts programmed into a CNC plasma cutting machine are set up and complete electronically, eliminating the need for handling the torch or metal during the cutting process. CNC plasma cutters also do not use or store any explosive gases.

Scope of Application

CNC Plasma Cutting Machine Video:

CNC Plasma Sheet Metal Cutting Machine Description:

A CNC plasma sheet metal cutting machine uses a plasma cutter to cut thin to thick metals along a multi-axis grid. The CNC method provides an advantage over handheld plasma cutting tools due to the cut being programmed and controlled by a computer instead of human motion.

.

.

Automatic Plasma Cutting Machine Parameters:

| Working area | 1300x2500mm (1500*3000/2000*3000/2000*6000mm) |

| Torch height controller | With |

| Working table | Saw tooth table |

| Plasma power supply | Hypertherm 125A (Hypertherm 65/85/200A) |

| Cooling system | Air cooling |

| Control system | F2300A control system |

| Flies transfer | USB interface |

| Transmission | X,Y-helical rack pinion, Z ball screw |

| Guide rail | Hiwin guide rail |

| Drive system | Japan servo motor and drivers |

| Arc | Untouched Arc Striking |

| Traveling speed | 0-40000mm/min |

| Working speed | According to the cutting thickness |

| Working voltage | Single phase 220V and 3 phase 380V/50HZ |

| Software | Fastcam |

| Rotary axis | With |

| Drilling head | With |

| Marking head | With |

Plasma Sheet Cutting Machine Details:

Multifunctional plasma cutting machine,with drill head and marking head, For multiple purposes

Rotary axis cutting

Saw tooth working table

F2300A control system

Hypertherm 125A (Optional:Hypertherm 65/85/200A)

Metal Plasma Cutting Machine Processing Samples:

CNC plasma machine uses a plasma cutter to cut thin to thick metals along a multi-axis grid. The CNC method provides an advantage over handheld plasma cutting tools due to the cut being programmed and controlled by a computer instead of human motion. CNC plasma is where high speed and precision meet low cost – among a vast array of additional benefits.

Plasma cutting is a high-tech cutting method that uses an ionised, focused jet of gas to slice through thin sheet metal. An internal, high-voltage electrode in the cutter rapidly heats a compound gas mixture to over 20,000 centigrade when switched on. Shielding gas is used as a propellant and barrier to focus and move the induced plasma from the ionisation chamber. The ionised, superheated, concentrated beam of plasma then melts and blasts any metal it touches. A clean, sealed cut is made each time.

1. VERSATILITY

One of the biggest benefits of CNC plasma cutting is that it is an extremely effective option for cutting both thin and thick metals, such as steel, stainless steel, brass, copper, and aluminum. CNC plasma cutting machines can also be used to help improve production speeds and reduce costs for a variety of different industries.

2. FAST CUTS

Since CNC plasma cutters are specifically designed to complete large-scale projects in a fraction of the time it would take to complete using a hand tool, CNC plasma cutting can help reduce the overall time spent on a project, while also producing cleaner cuts. CNC plasma cutting machines can be programmed to cut a wide range of diverse shapes, making it a much more efficient means of completing cuts on short notice.

3. PRECISION

CNC plasma cutters are operated using a computer program that is incredibly precise. Once a cut has been programmed into the machine, the plasma torch will follow the exact path created by the computer, providing a reliable and consistent cut every single time.

4. EASE OF USE

While most metal cutters require a lot of training and experience to use extremely well, CNC plasma cutters are easier to use and do not require as much training to handle properly. This means that CNC plasma cutting machines can help minimize the overhead costs and downtime associated with training new employees.

5. INCREASED SAFETY

Since CNC plasma cutters are computer operated, they are much safer to use than other metal cutters. All cuts programmed into a CNC plasma cutting machine are set up and complete electronically, eliminating the need for handling the torch or metal during the cutting process. CNC plasma cutters also do not use or store any explosive gases.

Scope of Application

content is empty!