Views: 15 Author: Site Editor Publish Time: 2021-10-19 Origin: Site

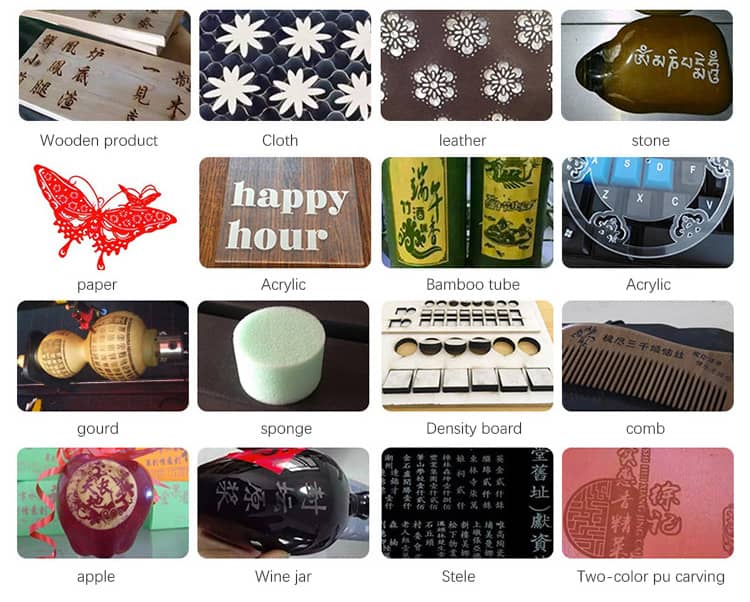

The CO2 laser cutting machine is one of the earliest gas lasers. Developed by Kumar Patel in 1964, it is still one of the most useful lasers today. With its high power and levels of control, CO2 laser cutting machine can be used for applications requiring precision, mass production, and most importantly, personalization. 40w Co2 Laser Engraving Cutting Machine are highly precise and can be used to create designs, decorations, and the like on just about any material you can think of, including wood, plastic, metal, and paper to name a few.CN¥14,987.36-CN¥15,625.12

Factors Affecting Laser Engraving

With the rapid development of optoelectronic technology, laser engraving technology has been applied more and more widely, and the requirement of engraving precision is higher and higher.

The four most fundamental factors that affect laser engraving are: engraving speed, laser power, engraving precision and material.

Engraving speed

Engraving speed refers to the speed at which the laser head moves, usually represented by an IPS. In the 1% to 100% range, the adjustment of laser engraving machine is 1%.

Speed is also used to control the depth of the engraving. For a given laser intensity, the slower the speed the laser engraving machine is, the greater the engraving or engraving depth is. You can adjust the speed by using the laser engraving machine panel or the printing driver of the computer.

Laser Power

Engraving intensity refers to the intensity of the laser engraving that is fired at the surface of the material. For a given sculpting speed, the greater the strength, the greater the depth of the engraving or engraving. You can use the engraving machine panel to adjust the intensity as well.

Engraving precision

40w Co2 Laser Engraving Cutting Machine is divided into lattice engraving and vector engraving according to engraving precision.

Lattice engraving

The laser head swings from side to side, engraving a line composed of a series of points at a time. Then the laser head moves up and down simultaneously to carve a number of lines, and finally forms the whole image or text. Scan graphics, text and vectorized text can be used lattice engraving.

Vector engraving

Unlike lattice engraving, vector engraving is carried out on the outer contour line of the image and text. We usually use this pattern to cut through wood, acrylic, paper and other materials.

To achieve a certain engraving effect on a specific material, it is required to absorb a certain amount of laser energy, which should be regarded as the laser energy absorbed by the material = laser power/engraving speed. Simply speaking, it is to increase the laser energy absorbed by the material, it is necessary to increase the laser power or reduce the engraving speed, and the final method depends on the material and the final engraving effect. Generally speaking, users will avoid reducing the speed and thus the production efficiency. Actually, it is not only the engraving speed but also the engraving precision that influences the engraving efficiency.

1) Red dot positioning Synchronize with the laser, which make the operation more convenient.

2) Ensure the accuracy higher than similar models on the market.

3) Knives and cellular dual cutting platform can meet the cut requirement of a variety of products.

4) DSP control system and Ruida board can ensure the engraving cutting task completed quickly at one time.

5) Make the processing of various thickness material more convenient.

6) Wide range of applications: Advertising industry, Office industry, Packing industry, Gift industry, Decoration industry, Printing Industry.

The 40w Co2 Laser Engraving Cutting Machine produced by igoldencnc can ensure the safety of material processing. The laser head will not directly contact the material, so it will not cause cutting accidents due to sharp tools like traditional cutting equipment. And it reduces the possibility of material deformation, resulting in a perfect cutting edge. The CO2 laser machine can effectively cut single or multilayer fabric materials.

Manual cutting with traditional tools is tedious and time-consuming. Imagine if you are in the production workshop of a textile manufacturing company, the cutting speed of workers will be much lower than that of a CO2 laser. With a laser cutting and engraving machine, the work will be completed faster and the workpiece quality will be higher. Choosing laser cutting technology will not only increase the output of the workshop, but also reduce labor costs, which will be more conducive to the development of the enterprise.

The laser cutting and engraving machine does not require any additional tools to create patterns on delicate fabrics and textiles. The machine's control system will automatically start the engraving and cutting of patterns according to your design. The whole process is fast and accurate.

Laser cutting technology minimizes errors and defects in the processing of fabrics and leather. As long as your programming is correct, the CO2 laser cutting machine will guarantee the same cut every time. The fabric processed by laser machine has no discoloration, deformation or uneven edges in any form.

The CO2 laser cutting machine produced by igoldencnc has an automatic roller table and feeding device. It adopts crawler working table and negative pressure absorb conveyor, make sure the smooth of materials when cutting. Working with auto feeding system, can meet the requirements for continuous and automatic batch cutting.、