Views: 14 Author: Site Editor Publish Time: 2021-09-29 Origin: Site

Since the advent of metal fiber laser cutting machine, the market demand of optical fiber cutting machine has been in a state of short supply in sheet metal processing industry.

With the increasing requirements of the fiber laser cutting machine market, from 3000W to 8000w, the fiber laser cutting machine used to look like a CNC machine tool, and now the output power surrounding 8000w has exceeded the original imagination!

Fiber Cutting Machine with flexible processing range, powerful cutting penetration and high processing efficiency has become a representative of the field of sheet metal cutting. In the future, more and more enterprises will enter the wave of 10000 watt laser cutting machine. The market of 10000 watt laser cutting machine will break out. Speculation or actual market demand?

1.Principles evaluating the fiber cutting machine quality

1. The cutting surface is smooth, no stripe, no burr, no brittle fracture.

When the fiber cutting machine cutting the thick plate at high speed, the molten metal will not appear at the bottom of the laser beam.

But it may spray after the laser beam.

In order to solve this problem, we only need to cut down the speed at the end of cutting process, thus greatly eliminating the appearance of texture.

2. The size of the cutting gap.

Cutting width has an important effect, when the thickness of the board increases, the width of the cut will increase.

Therefore, in order to ensure the same high accuracy.

No matter how wide the cutting width is, we should keep the work piece constant in the laser cutting machine area.

3. The perpendicularity of the cutting seam is good and the heat affected zone is small.

In general, the perpendicularity of the section under 5MM is not the most important factor for the cutting of the metal laser cutting machine.

But for the high-power laser cutting, the perpendicularity of the cutting edge will become very heavy when the thickness of the material is more than 10mm.

4. No material is burned, no melting layer is formed and no large slag is formed.

The slag of the optical fiber cutting machine is mainly reflecting in the deposition and cross section burr.

And the formation of the burr is one of the important factors that affect the quality of the fiber cutting.

Because we need additional work to eliminate burrs.

The severity and number of burrs can directly determine the cutting quality.

In addition to the above four principles, the state and final forming of molten layer in laser cutting process directly affect the quality evaluation indexes mentioned above.

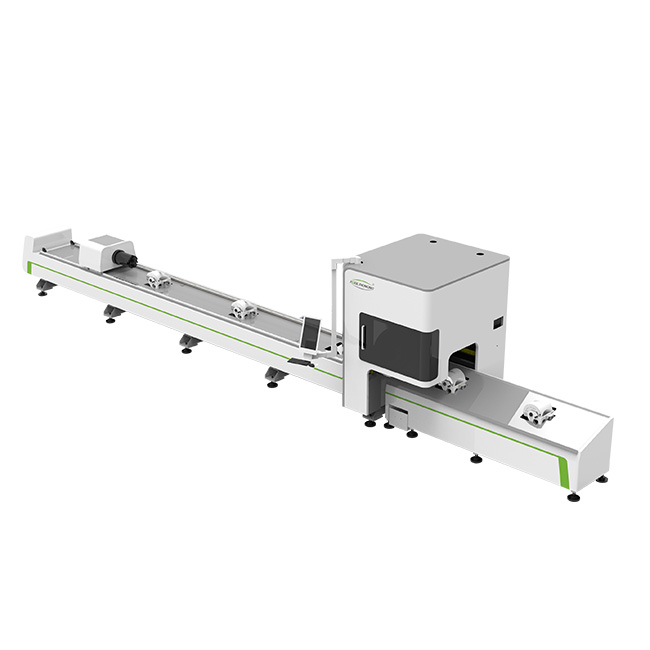

Fiber laser cutter's configuration

1.Swiss brand Raytools laser cutting head ,Germany brand Precitec laser cutting head as optional

2.Japan Yaskawa servo motor and drivers

3.Germany Atlanta Gear and Rack

4.French Motoreducer ,Germany Neugart Reducer as optional

5.IPG Laser source or Raycus laser source

6.LF3015GCR equipped with exchange table and control cabinet

7.Taiwan Hiwin linear guide rail and cypcut operating system

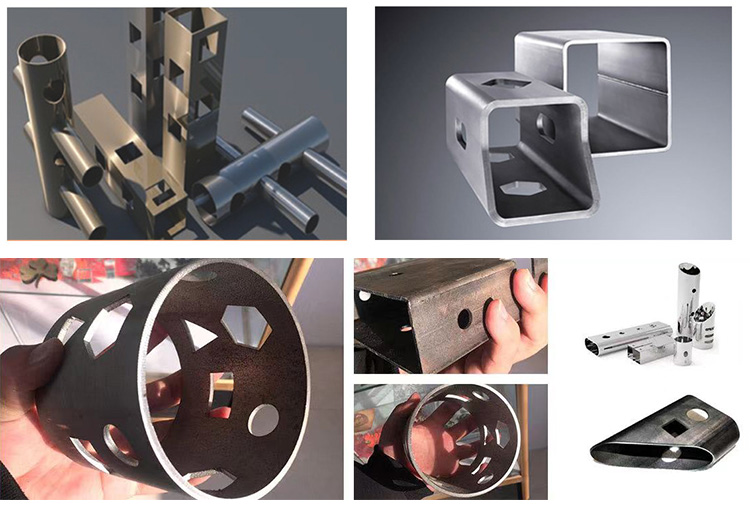

Scope of Application