Views: 7 Author: Site Editor Publish Time: 2021-09-27 Origin: Site

CNC Acrylic Cutter For arge-character cutting, sign making, cutting PVC, crystal plate, acrylic, aluminium plate engraving and cutting, led / neon groove, hole-shaped literal cutting, plastic light box mold making;

Now, we’ll showcase all of the pros of working with a laser cutter for acrylic. Lasers cutters make cutting acrylic a breeze and streamline your processes. A laser cutter for acrylic makes it possible to quickly change designs, as well as produce the same design over and over with perfect results every time. Laser cutters are also easy to use, as they function as a printer. There is also less margin for error; a laser cutter is computer-based and works off of the X and Y-axis.

CNC laser cutter acrylic features:

* V industrial led design, more beautiful

* DSP control system, easy to use.

* Stepper driving, or servo driver optional

* TBI Square rail

* Vacuum adsorption table surface, can fix the materials easily

* 12mm industrial class thick steel weld body and frame

Step-by-Step Guide on CNC Acrylic Cutter

Now, when you’ve chosen the acrylic, bit, and design, begin with cutting acrylic.

Step 1:- First things first, you’ve to set the feed rate according to the bit size. The most recommended range is between 75-300 IPM. High feed rates work best with large-sized bits. Smaller bits need a lower feed rate.

Step 2:- In this step, you’ve to set the RPM. The recommended value is 18,000 RPM for optimizing the spindle’s ability to cut through the acrylics, without melting the acrylics.

Step 3:- In the third step, you’ve to set the cutting depth. Experts suggest that cutting depth must be 1/2 of the diameter of the bit. It prevents the bits from breaking.

Step 4:- In the fourth step, you’ve to begin cutting with a ramp. You can select the option within the software. Opting for ramping rather than plunging is to deter distortion

Step 5:- Now, you’ve to secure the acrylic material on the CNC router table.

Step 6:- Finally, run the CNC router for cutting acrylic in a design you want.

CNC Acrylic Cutter Parameters

| Model | iGR-FT 3015 | |

| Working area/ Tube length | 3000*1500mm/ 6000mm | |

| X axis stroke | 1500mm | |

| Y axis stroke | 3000mm | |

| Z axis stroke | 300mm | |

| Tube diameter | 20-220mm | |

| Accuracy | X, Y axis positioning accuracy | 0.05mm |

| X, Y axis repositioning accuracy | 0.03mm | |

| Speed | W axis rotate angle | n*360 |

| W axis max. ratate speed | 80rpm | |

| X, Y axis max. running speed | 150m/min | |

| U axis max. positioning speed | 800mm/s | |

| X, Y axis max. accelerated speed | 1.5G | |

| Power supply | Phase | 3 |

| Nominal voltage | 380V | |

| Frequency | 50/60Hz | |

| Protection grade | IP65 | |

| Machine body | Max. working loading | 1000kg |

| Body weight | 2600kg | |

| Size(L*W*H) | 8060*3000*1965mm | |

| Laser power | 500w/ 750w/ 1000w/ 1500w/ 2000w/ 3000w/ 4000w/ 5000w/ 6000w/ 8000w/ 10000w/ 12000w | |

| Worktable optional | 4000*1500mm/ 4000*2000mm/ 6000*2000mm/ 6000*2500mm | |

| Tube length optional | 3000mm/ 9000mm | |

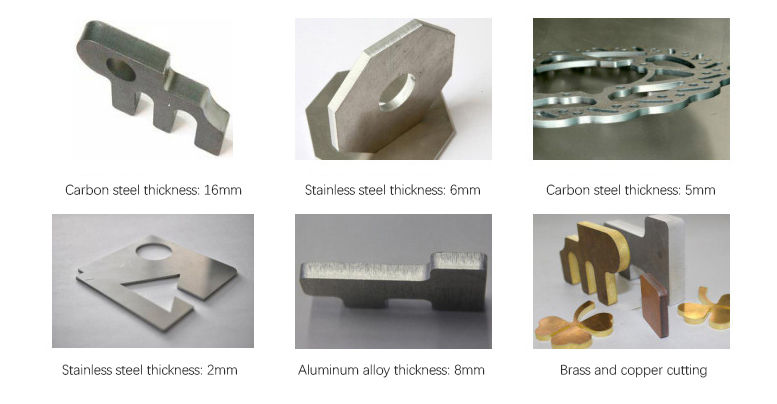

Application examples of CNC Acrylic Cutter

Applications

The laser beam is the universal "tool" for acrylic processing regardless of the shape and material thicknesses. The advantages of laser cutting are undisputed in the plastics and advertising technology sector.

Advertising technology

Digital printing

Shop and exhibition stand construction

Architectural model construction

Displays

POS materials

Letters

Outdoor and indoor signs

Acrylic trophies

Scope of Application