Views: 22 Author: Site Editor Publish Time: 2021-11-23 Origin: Site

What is a laser pipe cutting machine?

Tubes and profiles are used everywhere – from mechanical engineering and system construction all the way to the furniture industry. Lasers have opened up new design possibilities, so more and more designers are taking advantage of the benefits of laser-cut tubes and profiles thereby considerably increasing demand. Discover all-round solutions for the world of laser pipe cutting machine and find out more about the igoldencnc Laser Tube machines.

Capacity up to O.D. 102 mm

700W Laser Source ( Standard ), 1000W and 2000W Laser Source ( Optional )

Max. Lengths of working piece is 1.5m,2m, 4.5m or 6m ( longer lengths by request )

Max. Wall thickness up to 6.0mm ( Mild Steel with 1000W Laser Source )

Automatic Bundle Loading System with Material Alignment

Multi-Axis CNC Controls with Touch Screen Interface

SOCO CAD-CAM system for Tubes and Profiles with built-in Nesting

SOCO i2 ( Intelligent interface) 3D operation software

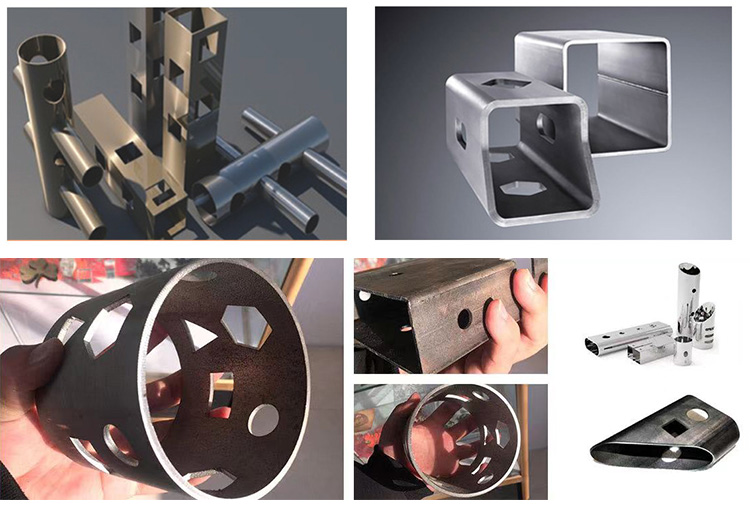

Cutting for round, square, rectangle and various profile shapes

Enclosed Workstation for maximum safety

Automatic Distance Control

Laser Resonator Cooling and Fume extraction systems

Scanning & Measuring of material before cutting

Compensation after measuring of material

Working principle of laser pipe cutting machine

The machine runs on laser light produced by fiber lasers. The laser is generated through an optical path that focuses the fiber laser beam on the substance used with a very high power density. Then, the laser beam is irradiated on the metal surface so that the metal reaches its melting point or boiling point. During this period, the high-pressure gas is connected to the fiber laser beam and blows away the molten or vaporized material.

Highlights Of Fiber Cutting Machine

1、Bevel Cutting

The maximum angle of the swing angle axis is ±160°; the maximum operating speed is 170m/min. The bevel cutting option enables high-quality bevel cuts of up to 45°.

Make it easier to cut irregular tubes, profiles and enable cutting workpieces to be seamlessly spliced.

2、Rapid Cutting

The pipe does not need to be moved when cutting the contour with a small figure, only the cutting head swings for rapid cutting.

This is a significant productivity advantage, especially in thinner materials.

Ordinary Tube Cutting VS Fiber Laser Bevel Cutting

In tube processing, many pipe fittings need to be welded after cutting, but it is difficult to weld on the vertical cut surface, and another groove is needed to ensure the welding is firm.

3、Ordinary Tube Cutting VS Fiber Laser Bevel Cutting

In tube processing, many pipe fittings need to be welded after cutting, but it is difficult to weld on the vertical cut surface, and another groove is needed to ensure the welding is firm.

Golden Laser bevel cutting technology can cut angles of different degrees on the edge of the pipe. Easy to splice, saving processes and significantly saving time and labor costs.

4、Golden Laser offers a full-automatic loading system to sort out a whole bundle of tubes and measure tube length automatically. Due to the intelligent unloading system, finished products and wastes will be separated from each other. Moreover, offcuts and wastes are collected together.

Save labor costs and improve efficiency.

5、Floating Support System

When cutting, the floating support device will automatically adapt to changes in pipe rotation without interrupting the production cycle.

More stable and high efficiency.

6、Pneumatic Chuck

High-speed pneumatic chuck, the maximum rotation speed is 120r/min. Thanks to the self-adaptive adjustment of the clamping force, the operation is more intelligent and simplified.

Time-saving and increasing productivity.

7、Welded Machine Bed

The maximum thickness of the welded plate of the machine bed is 25 mm, and the maximum weight is 7 tons, which is stable and not easily deformed.

Longer serviceable life, more stable, anti-shocking, and accurate.

8、Optional Automatic Slag Removal: Keep the inner wall is clean and smooth.

Improve the quality of the finished products.

Scope of Application

The advantages over traditional processing techniques are the following:

It has high cutting accuracy and the contour accuracy can reach ± 0.05mm.

The kerf is flat. with no burr. fine slit and less material lossIt is non-contact processing and laser cutting of the heat-affected zone is very small, with almost no deformation.

It has high cutting efficiency, which can achieve mass productionIt has good flexibility,

it can change or replace the product at any time with the use of the professional CNC system and suite of material programming software.