Views: 13 Author: igoldenCNC Publish Time: 2021-10-18 Origin: igoldencnc

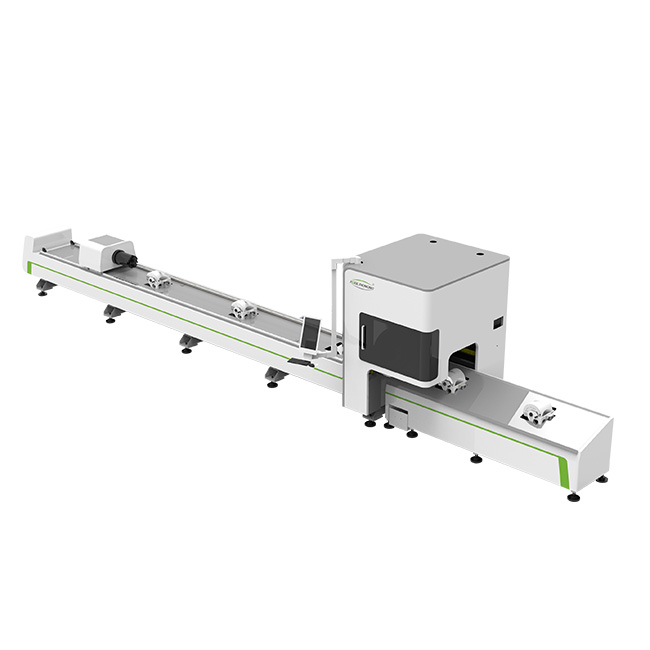

Tube cutting machine is a machine tool used for cutting various types of tubes, pipes, and profiles made of metal, plastic, or other materials. These machines are commonly used in industries such as automotive, construction, and manufacturing for cutting tubes and pipes to precise lengths and angles.

Tube cutting machines typically employ various cutting methods, such as sawing, milling, or laser cutting, depending on the type of material and the required precision. Some machines also have the ability to perform additional operations, such as drilling, notching, and marking.

Tube cutting machines are an essential tool for many industries that require precise and reliable cutting of tubes and pipes. They offer high accuracy, speed, and efficiency, making them a valuable asset in many manufacturing processes.

The tube cutting machines offers users a high degree of flexibility by combining a variety of laser processes into one machine. Angle cutting, slotting, marking, notching, and hole marking are all combined in this machine, making it an ideal solution for a wide range of applications.CN¥54,383.00-CN¥57,582.00/

1. Automatic cutting and blanking; the Tube cutting machines adopts a dual-drive pneumatic chuck rotation structure (active shaft and driven shaft), the active shaft starts the chuck to clamp the tube and fix it, and then the tube is carried out by the three-dimensional movement of the machine For cutting processing, the driven shaft starts the chuck to move along the workpiece axis with the worktable, and the automatic cutting and blanking function of the metal pipe can be seen.

2. Numerical control cutting technology; the cutting control software that comes with the Tube cutting machines provides advanced cutting technology and rich cutting experience so that cutting operators can achieve high-quality and high-efficiency CNC cutting through the skilled use of the control system.

Tube cutting machines sequence

1. Turn off the exhaust fan or dust collector.

2. Turn off the high voltage of the fiber laser, return to the origin of the machine tool, then turn off the control system as required, press the power off button after completion, turn off the power of the control system, and turn off the main power switch of the machine tool.

3. Turn off the chiller.

4. Turn off the refrigeration dryer and control valves for each gas path.

5. Turn off the air compressor.

6. Turn off the power switch of the fiber laser or leave it on to keep the fiber laser in a charged state, and you can quickly turn it on the next day.

7. Turn off the regulator.

8. Turn off the power switch of each branch and turn off the main power switch of the fiber laser cutting machine.

Scope of Application