Views: 13 Author: Site Editor Publish Time: 2022-06-29 Origin: Site

At present, people's aesthetics are constantly changing, and they are more and more advocating nature, focusing on beauty, and paying more attention to health, pollution-free and pollution-free. Natural stone is used for architectural decoration and craftsmanship with its brilliant color, stable physical and chemical properties and good processing performance. products have been widely used. Among them, carved products such as reliefs, depictions, photo frames, hollow panes, and fireplace facings for interior decoration are developing rapidly, and are developing in the direction of artistic, high-grade, and large-scale applications. In the next step, with the development of science and technology With the continuous development and the continuous progress of human understanding, it is an inevitable trend of social development that medium and high-end CNC machinery replaces manual work. It can be seen that the development potential of Granite Carving Machine is huge.

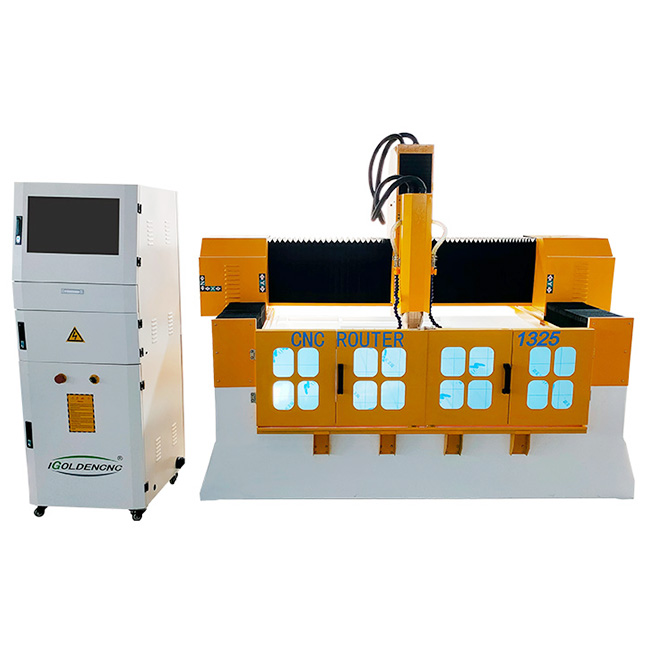

Stone engraving machine is a kind of professional CNC mechanical equipment that requires very high professional knowledge. It consists of engraving machine body, circuit system, system control card, control software, programming and design software. The mechanical bed part is the most valuable part of the stone engraving machine. It is the basis for the normal use of the machine and the accuracy of engraving. For the whole machine, this standard foundation is like a human skeleton and a car's chassis. With the development of the industry, simple engraving machines can no longer meet the needs of the society, the changes in processing technology and the rapid development of numerical control technology, more new types of cnc granite engraving machine, multi-head automatic tool changing engraving machines and other mid-to-high-end engraving machines came into being.

After purchasing a cnc stone engraving machine, many manufacturers often neglect the maintenance of the equipment. While considering the benefits of the equipment for the company, it is also necessary to consider that the stone machine also needs normal rest and maintenance. A few things to note:

1. The continuous running time is less than 10 hours a day to ensure the cleaning of the cooling water and the normal operation of the water pump. The water-cooled spindle motor must not be short of water, and the cooling water should be replaced regularly to prevent the water temperature from being too high.

2. The machine should be cleaned in time after use. The stone engraving machine will generate a lot of dust during use, and too much dust will have a great impact on the life of the stone engraving machine. Therefore, be sure to clean the dust on the platform and transmission system after each use, and regularly clean the dust on the platform and transmission system.

After purchasing a stone engraving machine, many manufacturers often neglect the maintenance of the equipment. While considering the benefits of the equipment for the company, it is also necessary to consider that the stone machine also needs normal rest and maintenance.

1. The continuous running time is less than 10 hours a day to ensure the cleaning of the cooling water and the normal operation of the water pump. The water-cooled spindle motor must not be short of water, and the cooling water should be replaced regularly to prevent the water temperature from being too high.

2. The machine should be cleaned in time after use. The stone engraving machine will generate a lot of dust during use, and too much dust will have a great impact on the life of the stone engraving machine. Therefore, after each use, be sure to clean the dust on the platform and transmission system, and regularly lubricate the transmission system (X.Y.Z three-axis).

3. If the machine is not used for a long time, it should be refueled regularly (weekly) to ensure the flexibility of the transmission system.

4. Regularly (according to the usage) clean the dust in the electric box, check whether the terminal screws are loose, and ensure the safe and reliable use of the circuit.

5. When the Granite Carving Machine is in use, be sure to cut off the power supply, and leave it after the display has no display and the main circuit power indicator is off, which can prolong the service life of the stone engraving machine electrical appliances.

The above are some points shared based on the design and use experience of the stone engraving machine, hoping to help new and old customers.

Lubricate the transmission system (X.Y.Z three axes).

3. If the machine is not used for a long time, it should be refueled regularly (weekly) to ensure the flexibility of the transmission system.

4. Regularly (according to the usage) clean the dust in the electric box, check whether the terminal screws are loose, and ensure the safe and reliable use of the circuit

5. When the stone engraving machine is in use, be sure to cut off the power supply, and leave it after the display has no display and the main circuit power indicator is off, which can prolong the service life of the stone engraving machine electrical appliances.