Views: 12 Author: Site Editor Publish Time: 2021-09-28 Origin: Site

What is a EPS Foam CNC Machine?

CNC stands for Computer Numerical Controlled, which refers to how a pre-programmed computer software is used to control the tools and machines that cut the foam, rather than manual machinery. Different types of CNC machinery are suited to work different materials, but CNC routers are the most common and are the type used for cnc router foam cutting.

EPS Foam CNC Machine are specifically designed to smoothly and precisely cut 3D shapes out of foam materials, such as polyethylene and polyurethane. CNC foam cutting machines can be used to create packaging, decor elements, props, displays, insulation and much more.

EPS Foam CNC Machine Features:

1. The Z axis can be heighten to 1000mm, which widens the working region so as to fit the large three-dimensional curved surface processing.

2. Big steel square tube structure,by seamless welding and hardening treatment, guarantee it to be strong, reliable and durable, with large bearing capacity and long working life.

3. EPS foam cnc router equipped with self-lubricating blocks,with four-row ball bearing and widened rail,so it can get equal force in all directions, to guarantee mechanical precision and strength.

4. Many optional configuration and OEM service available.According to your requirement, different configurations of foam cnc router will be offered.

5.Imported high-precision ball screw and Taiwan Hiwin linear square rails, which move smoothly to ensure the machining precision.

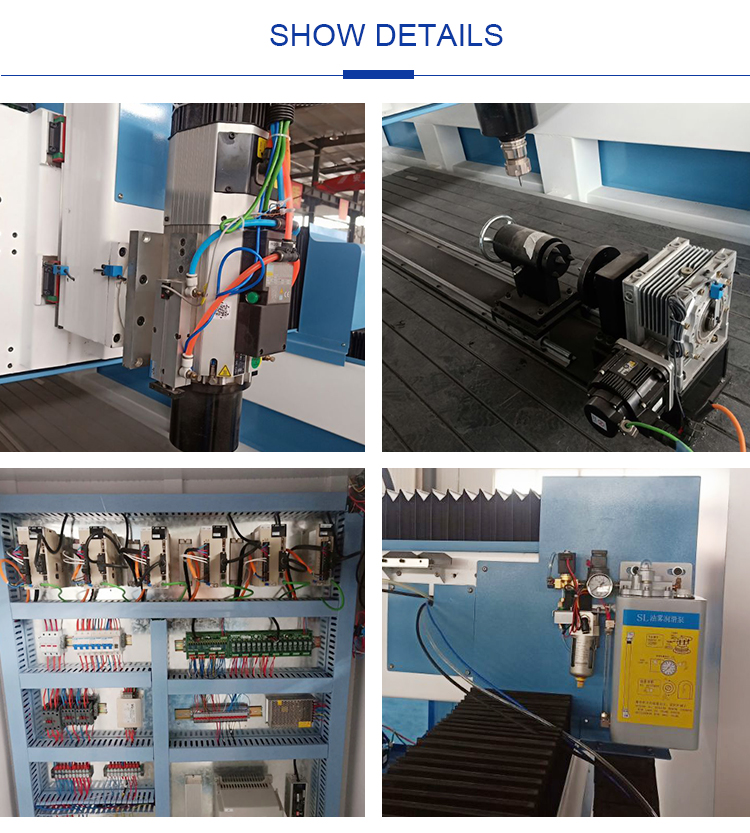

• Strict quality control is implemented from the beginning. All the precision parts used on the cnc router foam cutter are strictly tested by the three-coordinate detector, and only the qualified items will go to the production process. Please refer to the picture below.

• In the design stage, we use computer-aided design software to optimize the whole machine construction design. Every detail is taken care of by us.

EPS Foam CNC Machine Parameter Configuration

Description | Parameters |

Working area | 1500*3000*800mm |

Table size | 2200x3650mm |

Transmission | X/Y rack and pinion, Z ball screw |

Table structure | Aluminum profile |

Spindle power | HQD 9KW |

Spindle speed | 18000RPM/MIN |

Travelling speed | 45m/min |

Working speed | 30m/min |

Working Delicacy | 0.02mm |

Repositioning Accuracy | 0.03mm |

Driver motor | Servo motor |

Control system | DSP/Nc studio Control System/Syntec |

Command Code | G Code*u00*mmg*plt |

Voltage | 3 Phase/380V/50HZ |

Software | Artcam/Type3,other CAD/CAM |

Scope of Application

cnc router foam cutting Applicable Processing

The mold industry: casting, automotive, wind power, ships, boats, aerospace industry, rail transport

The instrument industry: three dimentional surface of large musical instruments, cutting and shaping

Applicable materials: polystyrene foam (EPS), and wood, timber and nonmetallic carbon hybrid materials.