Views: 81 Author: igoldenCNC Publish Time: 2026-01-07 Origin: igoldenCNC

In the world of industrial manufacturing, the need for strong, precise, and durable joints has never been more important. Whether it's for automotive production, electronics, or heavy machinery, welding is a fundamental process that ensures the structural integrity and longevity of a product. Among the many welding methods available today, laser welding machine has emerged as a revolutionary technology offering high precision, minimal distortion, and seamless, strong joints.

Laser welding machines are increasingly being adopted across industries due to their advanced capabilities, speed, and efficiency. In this blog, we will explore what a laser welding machine is, its advantages, applications, and why it is becoming a go-to solution for creating seamless and durable joints in various industries.

Laser welding machine is a high-tech welding tool that uses a focused laser beam to melt and join materials, typically metals, together. The laser energy provides a concentrated heat source that can be precisely controlled, allowing for a more accurate and clean weld than traditional welding methods like arc or MIG welding.

Laser welding works by directing a laser beam, often created by a solid-state laser (like a diode or fiber laser), onto the area where the two pieces of metal are to be joined. The intense heat generated by the laser beam melts the metal, and when it cools, it forms a strong, durable bond. Because of the concentrated nature of the laser, the heat-affected zone (HAZ) is much smaller compared to other welding methods, which reduces the risk of distortion and thermal damage.

Laser welding can be performed in two main ways:

Conduction Welding: In this technique, the laser beam is absorbed by the surface of the workpieces. The heat melts the material to create a small molten pool that solidifies into a joint.

Keyhole Welding: This method allows the laser beam to penetrate deeper into the material, creating a keyhole effect. This process provides deeper penetration, making it suitable for welding thicker materials.

Laser welding is favored for applications where high precision and minimal distortion are critical.

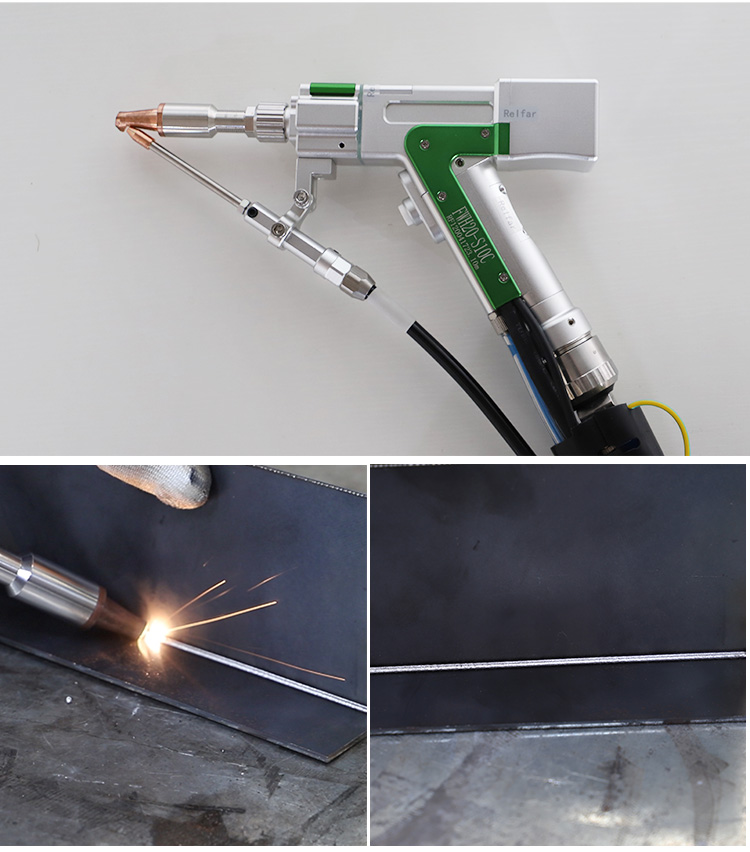

The 1000W/1500W 5-in-1 handheld metal laser welding machine represents a convergence of advanced technologies, combining the power and precision of laser welding with versatility and portability.

The portable 5-in-1 handheld metal laser welding machine is a laser machine launched by IGOLDENCNC. The product is a lightweight, portable, easy to operate, economical and intelligent innovative product. It integrates five different functions and can efficiently process five kinds of workpieces: welding/cleaning/cutting/welding seam cleaning/energy storage welding, which can meet different customer needs.

To provide a more efficient and flexible solution for the market, the system comes with a process parameter library for common materials and thicknesses.

| 5-in-1 Handheld Metal Laser Welding Machine | |

| Item | Dual axis |

| Fiber Interface | QBH |

| Wavelength range | 1070±20nm |

| Power | 1000w 1500w2000w 3000w |

| Collimating focal length | 50mm |

| Focus length | 150mm |

| Focus adjustment range | -10mm~+10mm |

| Spot adjustment range | 0~5mm |

| Swing type | —、○、8、∞、◎、△ |

| Auxiliary pressure | ≤1Mpa |

| Laser head weight | 0.8Kg |

Laser welding is renowned for its precision. The small and focused laser beam allows for extremely fine and accurate welds, which is ideal for applications that require tight tolerances. The machine can create welds as narrow as 0.2mm, offering better control and minimizing the risk of errors. This makes it perfect for high-end products where the slightest imperfection can compromise performance, such as electronics and medical devices.

One of the standout benefits of laser welding is its ability to minimize the heat-affected zone (HAZ). The smaller HAZ means that the surrounding material is subjected to less thermal stress, reducing the likelihood of material warping, distortion, or degradation of properties. This feature is particularly valuable when working with delicate materials or thin sheets that might be damaged by excessive heat.

Laser welding machines are faster than many traditional welding methods. The high-intensity laser beam can melt the material almost instantaneously, enabling faster production times. This speed makes laser welding particularly advantageous in high-volume manufacturing environments, such as the automotive or electronics industries, where throughput and efficiency are paramount.

Laser welding produces clean, high-quality welds that require minimal post-weld cleaning or finishing. Because the heat is applied so precisely, the weld area is often smoother, and there is little to no spatter or debris to clean up afterward. This is especially advantageous in industries where cleanliness and appearance are critical, such as the food processing or medical device sectors.

Laser welding machines are capable of welding a wide variety of materials, including metals, plastics, and alloys. They can be used to join materials with differing thicknesses and types, making them extremely versatile. Whether you need to weld stainless steel, aluminum, titanium, or even gold, laser welding provides the flexibility to work with a range of materials.

Laser welding is especially useful in situations where traditional welding methods cannot reach. The precision of the laser allows it to be directed to hard-to-reach locations, such as deep grooves, corners, or spots with limited accessibility. This capability makes laser welding ideal for intricate parts, small assemblies, or products that require complex welding operations.

Laser welding machines have found applications across a wide variety of industries, offering specific advantages in each. Here are some of the key areas where laser welding is used:

Automotive Industry

In the automotive industry, laser welding plays a crucial role in the production of high-performance vehicles. It is used to weld various components, including body panels, chassis parts, exhaust systems, and fuel tanks. The precision of laser welding ensures that the joints are strong, durable, and lightweight, which is essential for automotive performance and safety.

Electronics Manufacturing

Laser welding is extensively used in the electronics industry, where high precision is required for soldering components like microchips, circuit boards, and connectors. It helps in the precise joining of thin, delicate wires and fragile electronic components without causing damage to surrounding parts. Laser welding also helps in hermetic sealing of devices like sensors, ensuring reliability and longevity.

Medical Device Manufacturing

The medical device industry requires precise, strong joints to ensure the functionality and safety of devices like surgical instruments, implants, and diagnostic equipment. Laser welding is ideal for these applications, offering clean, precise welds with minimal thermal distortion, which is crucial for maintaining the integrity of medical-grade materials.

Aerospace

The aerospace industry relies on laser welding to create lightweight, durable joints in components subjected to high-stress conditions. From the body panels of aircraft to engine components and structural parts, laser welding ensures that joints can withstand the demanding environments they face, including extreme temperatures and pressure changes.

Jewelry Industry

Laser welding has become a standard technique in the jewelry industry, especially for repairing and resizing precious items like rings, bracelets, and watches. The fine control offered by the laser enables jewelers to weld even the tiniest parts without damaging the surrounding material, allowing for delicate, high-quality repairs.

Energy Sector

In energy production, particularly in the oil and gas industry, laser welding is used for joining parts of pipelines, pressure vessels, and turbine blades. The high precision and durability of laser-welded joints help ensure that these critical components perform reliably in challenging conditions.

Laser welding machines operate by generating a high-powered laser beam that is focused onto the surface of the material being welded. Here’s a simplified breakdown of the process:

Laser Generation

The laser is typically generated using a diode, fiber, or YAG (Yttrium Aluminum Garnet) laser, depending on the machine's specifications and the material being welded.

Beam Focusing

The laser beam is then focused through optics to achieve the desired focal length. This allows the operator to control the size and intensity of the beam, ensuring optimal energy concentration on the workpiece.

Melting and Fusion

The focused laser energy heats up the material at the point of contact, causing it to melt. The molten material from both parts fuses together to form a joint. In the case of keyhole welding, the laser can penetrate deeper into the material for thicker joints.

Cooling and Solidification

As the laser moves along the joint, the material begins to cool and solidify, creating a strong, durable bond. In some cases, additional cooling methods such as gas shielding or forced air can be used to control the cooling rate and prevent defects like cracking or warping.

When selecting a laser welding machine, several factors should be considered to ensure that it meets your specific needs:

Material Compatibility

Ensure that the laser welding machine is capable of welding the materials you intend to use. Some machines are better suited for specific metals or alloys, so understanding your material requirements is essential.

Laser Power

The laser power, measured in watts, determines the penetration depth and speed of the welding process. For thicker materials, higher-powered lasers may be necessary.

Welding Speed and Efficiency

Consider the speed of the welding process, especially if you are involved in high-volume production. Faster welding speeds can help reduce manufacturing costs and increase throughput.

Precision Requirements

If your work involves high-precision joints, choose a machine with excellent beam focus and control mechanisms to ensure that the laser delivers accurate results.

Size and Automation

Depending on your production scale, you may need a machine that offers automated features such as automatic beam alignment, position sensors, or robotic arms to handle larger workpieces.

Laser welding machines represent a leap forward in welding technology, offering high precision, minimal distortion, and fast, durable joints. Whether you’re working in the automotive, electronics, aerospace, or medical device sectors, these machines provide a versatile, reliable solution for creating high-quality welds. With the ability to weld a wide range of materials, laser welding machines are a game-changer in many industries, helping manufacturers meet high standards for strength, accuracy, and efficiency.

As industries continue to demand more precision and faster production times, laser welding technology will only become more indispensable. Investing in a laser welding machine today can help you stay ahead of the competition, improve product quality, and enhance manufacturing capabilities for years to come.