Views: 15 Author: Site Editor Publish Time: 2022-04-15 Origin: Site

Versatility of mobile plasma cutter

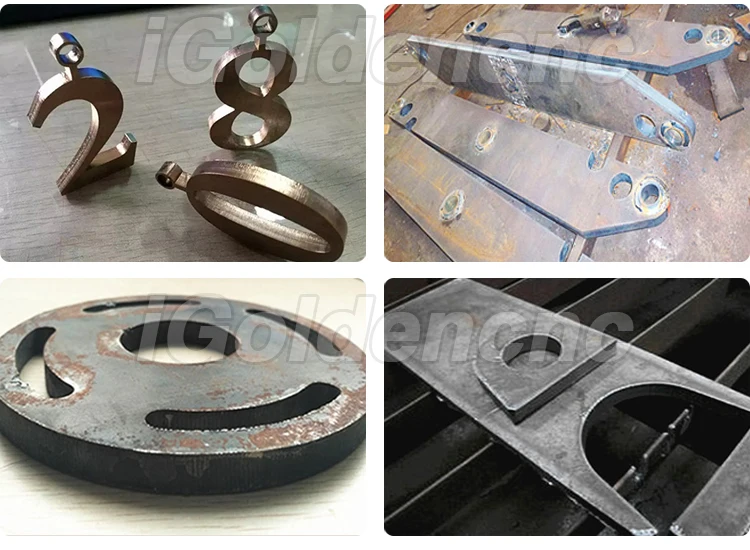

The versatility of portable plasma cutting machine is undeniable. The CNC plasma machine’s versatility is one of its key advantages, as it is an effective way to cut both thin and thick materials in less time compared to handheld machines. This type of plasma cutter is commonly used to cut a wide range of metals, including:

machine low cost

Steel and stainless steel

Aluminium, copper and brass

Apart from the materials it is one of the most commonly used machine to cut,

mobile plasma cutter is also used a in a vast array of settings, and industries to improve production speeds and reduce costs at the same time.

Automatic torch height controller:

Capacitive automatic torch height controller helps maintain constant distance between torch and

work piece during the entire cut motion. This helps counter the waviness and undulations present in

the work piece.

Oxyfuel Machine is upgradable in future to work with a Plasma power source for plasma cutting.

The plasma cutting process, as used in the cutting of electrically conductive metals, utilizes electrically conductive gas to transfer energy from an electrical power source through a plasma cutting torch to the material being cut.

Carbon Steel Plasma Source Cutter advantages:

1. The portable cutting machine is small and light, and it can be cut directly on the steel plate or used for fixed cutting table. Does not occupy a fixed space.

2. The machine is cheap and economical. It is an upgraded product of manual cutting machine and semi-automatic cutting machine. Can realize automatic batch cutting.

3. Install the plasma automatic height controller. During the machine cutting process, the cutting torch can automatically rise and fall according to the unevenness of the steel plate to prevent the cutting torch from crashing, extend the life of the cutting torch, and save costs.

4. The control system has a graphic display function, which can observe the cutting process in real time. And supports 9 languages, it is easier to use your own native language to operate. With power-off memory function, you can continue cutting after the power-on, saving time for cutting from the beginning. There are 48 kinds of graphics, regular graphics can be directly used, change the size, set the quantity, save the computer drawing time and improve efficiency.

5. Using well-known brand stepper motor driver, stable operation and low noise.

6. Equipped with fully automatic nesting software, which saves time for typesetting and improves the utilization rate of steel plates.

7. Optional: remote control, the control distance is 30 meters, the operation is more convenient.

8. Optional: Plasma anti-collision holder, when the torch hits the steel plate, it will automatically stop to prevent the torch from crashing and save costs.

9. Optional: flame automatic igniter, to avoid burning hands when using a lighter to ignite, and to ensure safety.

10. It can be equipped with various power plasma power sources, such as 100A, 130A, 200A, etc, to achieve plasma cutting. The plasma cutting speed is 3-5 times that of flame cutting, which improves production efficiency.

Portable Plasma Cutting Machine Application: