Views: 21 Author: Site Editor Publish Time: 2021-11-19 Origin: Site

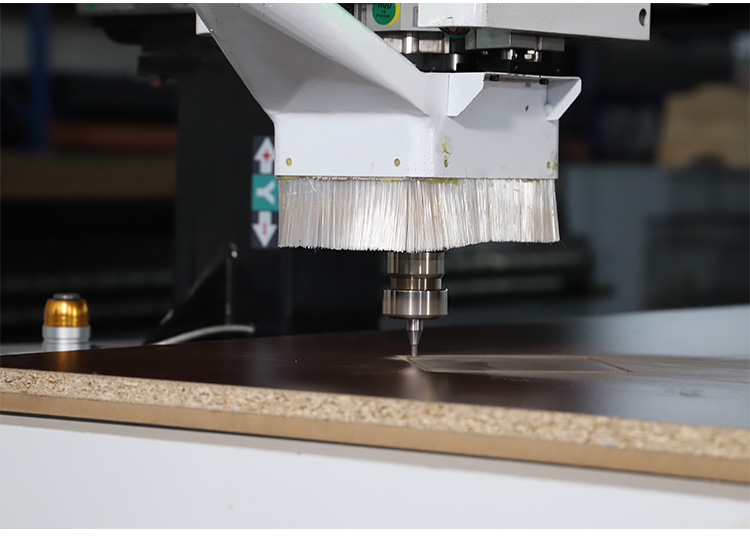

This automatic tool changer for cnc router is a multifunctional machine,this machine contains ATC Function.So it can be used in making cabinet furniture.The router atc also come standard with horizontal spindle and rotary spindle.The horizontal spindle can be used for drilling and milling the keyhole and hinge for door making. The rotary axis can be used for making furniture legs, such as chair legs, table legs, sofa legs, and many other three-dimensional products.

First, the manipulator tool change way

Generally equipped with manipulator tool changing mechanism of the knife library often use disk - type knife library. The so-called manipulator tool change means, is refers to in the knife change, by the manipulator to grasp the knife, knife selection and knife change. Responsible for transferring the cutter between the cutter store and the spindle of the CNC machining center, sending the replaced cutter back to the cutter store, and then pushing the cutter needed to be used to the spindle. The feature of this knife change is that the new knife to be used and the old knife to be used are grabbed at the same time. That is to say, the knife grasping and changing at the same time, so compared with other tool changing methods, it has a faster tool changing speed, the motion range of each mechanical element is smaller and so on. Is now more mainstream way of knife change.

Second, the direct way to change the knife

The so-called direct tool changing means that the tool changing process is completed by the tool library and the spindle box. This is the most direct tool changing way. The general configuration of the knife library is the hat type. According to whether there is any displacement in the tool changing process, the direct tool changing mode can be divided into two types: the shift mode of the tool changing and the fixed mode of the tool changing. In the shifting mode of the knife library, the knife library can be moved. Before changing the knife, the knife library enters the knife changing area, and exits the area after changing the knife. This tool changing mode has more movement, more exquisite layout and less flexibility and adaptability due to the knife store. In the fixing mode of the knife storehouse, the main tool selection is carried out by the movement of the headstock. The knife stock may be stationary or it may rotate only in position. The former can only be used for sequential knife selection, which is suitable for numerical control machining centers with fewer tools, while the latter can realize transposable knife selection. This way of knife selection reduces the movement of the knife library, greatly simplifies the design structure of the knife library, and the control of the knife changing process is simple and reliable. The direct tool changing mode is characterized by slow tool changing speed and high failure rate, and it is only used on early models.

Third, the tower head tool change way

The turret head is a tool change mode in which the desired cutter is moved to the appropriate position by the rotation of the brick tower. Generally, it is a sequential tool change, with advantages of compact structure and very short tool change time. Generally, it is more widely used in the processing of slender workpiece such as crankshaft and complex processing occasions that need to complete multiple procedures.

The automatic tool changing device of turret head is similar to that of direct tool changing, which can be divided into two ways: tool changing of turret tool holder and tool changing of brick tower spindle head. The tool changing mode of turret tool holder is realized automatically by rotating the turret head. The turret spindle also needs to be equipped with a turret for tool changing. However, the turret spindle is connected not with a knife rest, but with a number of sub-spindle heads distributed in the shape of octopus tentacles in different directions. Each spindle head is equipped with the cutting tools needed in each process in advance.

4 Axis CNC Router 2130 Details:

Rotary Spindle 4 Axis ATC CNC Machine Application

1. Advertisement: engraving and cutting of various labels and number plate, marble, etc for artistic effects on materials including marble, brass, steel, and other metallic material.

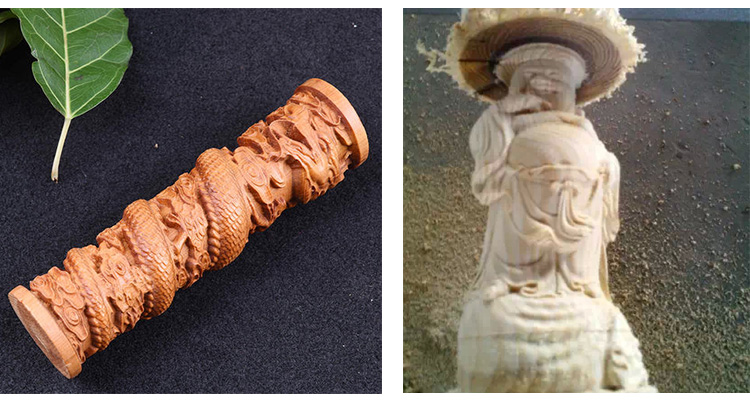

2. Crafts: engraving characters of any language and patterns on gifts and souvenirs, primitive processing and shaping of artistic crafts, and stiletto.

3. Moulding: engraving delicate letter and flower pattern, primitive and fine processing of the small mould.

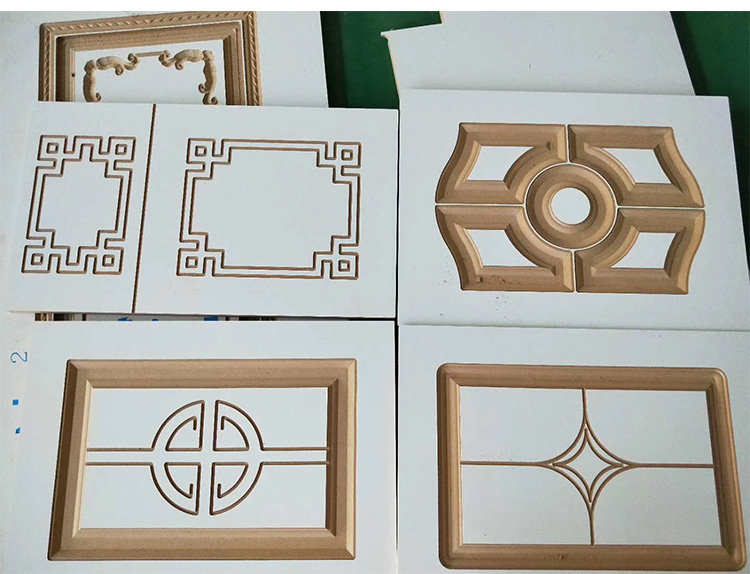

4. Architectural models: engraving fine window, fencing and wall patterns, etc.

5. Seal: engraving seals and medal on materials such as buffalo horn, wood etc.

1. Improve the utilization rate of the plate: Because the material is cut with a milling cutter, the direction can be adjusted arbitrarily, and the material can even be nested, and the utilization rate of the plate can reach more than 93%.

2. Professional software support: professional software support, NC file output, no error in cutting, zero error, no accidental error cost, no waste.

3. Special-shaped support: arc, chamfer, trapezoid, tie box can be formed at one time, eliminating the need for later engraving, high sheet utilization, and eliminating the need for later manual secondary processing.

automatic tool changer for cnc router application:

1. The process of automatic order removal, optimization, design, cutting, drilling, milling, troughing, automatic cutting and other processes of the cabinet are completed at one time. Four-process blanking machine, four-step blanking machine advantages, CNC blanking machine.

2. Wood door and furniture decoration industry: solid wood and composite door, cabinet door, large area plate plane carving, solid wood carving and milling, panel furniture carving, antique mahogany furniture carving, solid wood art mural carving and other industries.

3. Wooden handicraft processing: clock frames, craft photo frames, thin aluminum plate handicraft carving and carving, electrical countertops, sports equipment. Four-process blanking machine, four-step blanking machine advantages, CNC blanking machine.

4. Electronic product industry: engraving and milling of circuit boards, insulating materials, LED display screens, household appliances (color TVs, washing machines, refrigerators) shells or models.

5. Musical instrument production industry: Carving the three-dimensional curved surface and shape cutting of musical instruments, such as engraving and milling of large and violin panels and heads.