Views: 8 Author: Site Editor Publish Time: 2022-02-11 Origin: Site

What is a stone engraving CNC?

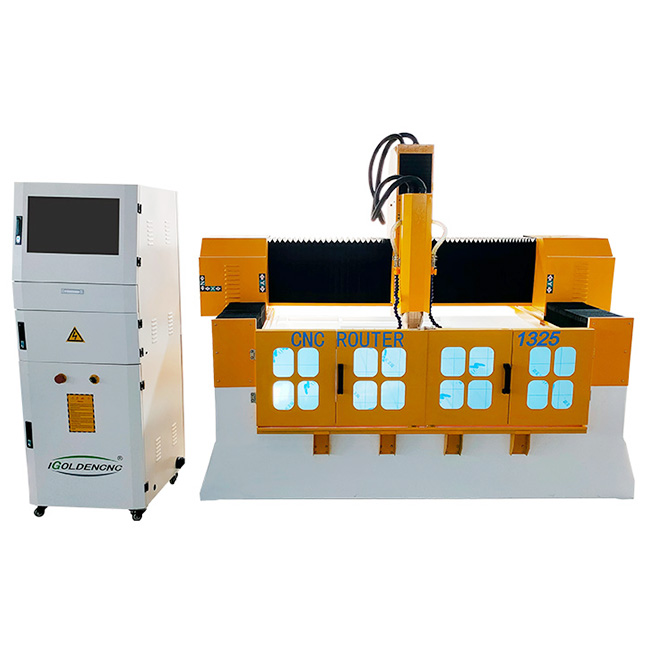

The stone engraving CNC is a machine tool computer-controlled and it is specially designed for all kinds of stone processing, such as marble, granite, sandstone, jade, quartz, etc. The stone CNC machine can do various processes such as carving, cutting, engraving, milling, punching, trimming, polishing, and so on. So the CNC stone router is also called: CNC stone machine, stone CNC router, CNC stone carving machine, CNC stone engraving machine, CNC stone cutting machine, tombstone engraving machine, headstone engraving machine, etc. As a stone CNC cutting machine. The stone CNC machine can meet the requirements of personalized home decoration and tooling art design. It can be used as advanced engraving processing equipment for decoration companies, handicraft industry, stone industry, the funeral industry, inscription industry, and ceramic companies. Recently, stone engraving machines have become more and more popular and welcome.

The brand of the engraving machine is different. At present, there are many manufacturers and brands of such equipment on the market, and the price will be affected by the brand.

The power of the engraving machine. Because the hardness of the wood material is relatively large, in general, woodworking engraving machines need to be equipped with a spindle motor with a higher power. The higher the power, the higher the price will be.

The beam of the engraving machine, some of the engraving machines on the market are made of steel, and some are made of aluminum, and the price difference is also very large.

In terms of transmission mode, the engraving machine is divided into a screw machine and a rack machine. The price of the rack machine is much more expensive than the screw machine. The screw machine is generally used in the advertising industry. Those who do mahogany furniture are also recommended to choose this Various model, and the rack machine, the transmission speed is relatively fast, generally used for cutting, wood door processing, etc. It is not that the rack machine is not suitable for the advertising industry, but the rack machine is used in the advertising industry, the cost performance is not great A bit overkill. The three axes of the screw machine are screw drives, the XY axis of the rack machine is rack drive, and the rack machine is dual drive.

The bed of the engraving machine is mainly divided into three types: channel steel, square tube, and cast iron. Those who are familiar with this equipment generally know that the bed of cast iron is good. If the square tube is thickened, the cost is more than that of cast iron. High and better stability than cast iron, requires specific analysis.

If it is also a rack machine, the price difference is also very large, which must be compared to each part of the engraving machine. For example, the main shaft is generally divided into water-cooled and air-cooled, and the price is different according to the brand.

Features of Stone engraving CNC :

One machine with multiple functions: one CNC Stone Quartz Router machine can replace many cutting and polishing machines and we can finish all quartz processing in only one machine. In this case, we can save time and improve production.

Very Easy to operate the machine: It takes only one or two days for machine operator to understand and operate this CNC Quartz Stone Router Machine. Any operator who can understand stone drawing can run this CNC machine easily. Image we are using different machines to process quartz counter top in different steps, we need to hire many workers for running each machines. Now with CNC Stone Counter top router machine, we need only one person to done all these work.

Good for environmental protection and health. CNC Stone Counter top router machine adopts water dedusting and water cooling system to avoid generating a lot of dust and refusing pneumoconiosis.

High automation and low cost. CNC Stone Counter top router machine can processing some counter top products with big size such as 3 meters and even bigger size. This is impossible to finish with manual stone polishing machine. We just need to enter some parameters on the computer screen such as cutting size, grinding angle etc, then machine will finish all jobs. Because we can do all work on one machine, it save both time and cost.

High precision and high quality. This cnc machining machine belongs to 5 axis CNC Stone cutting machine, it High precision, stable quality, high productivity, improvement of working conditions and conducive to modernization of production management.

Application

1.Stoneworks: 3D/2D stone carving, Embossment, Line engraving Cutting,

Edge inversing, Drilling on Natural stones, Granites, Artifical stones, Tombstones,

Milestones, Ceramic, etc.Stone cnc 1325

2.Die industry: copper sculpture,aluminum engrave,metal molds,plastic sheeting,PVC ,etc

3. Heavy Cut Machine for Pyramid Type Stone

4. It is widely used in the gemstones production. Stone cnc 1325