Views: 49 Author: Site Editor Publish Time: 2022-05-09 Origin: Site

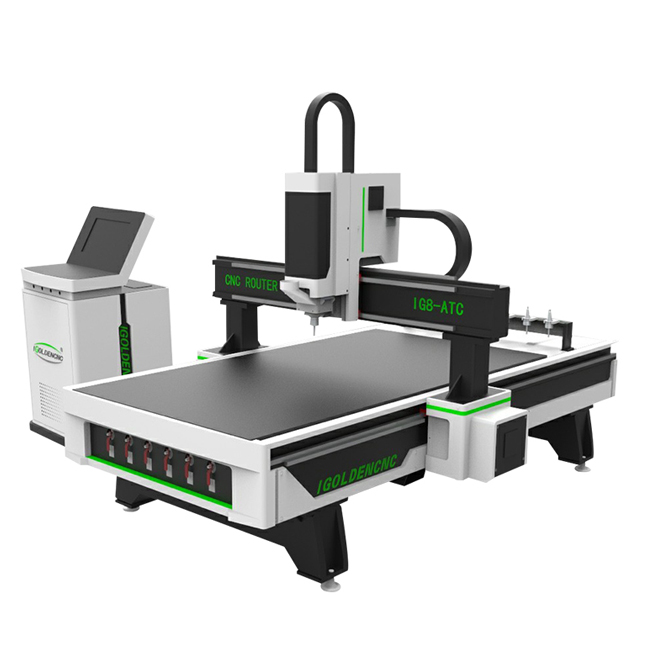

Automatic tool changer cnc is a relatively common equipment on the market, and the price of this equipment is not exactly the same. Many companies may find it inexplicable when choosing, so they don’t know how to choose the right one for them. IGOLDENCNC is your best choice.

ATC wood CNC router machine is a type of heavy-duty and multi-purpose CNC woodworking machine with automatic tool changer for carving, milling, drilling, grooving, and cutting from igoldencnc. It has the industrial features of high precision, high speed, constant torque, low runout, strong stability and long life. cnc router tool changer is CNC wood router related to the hand-held router by computer-controlled. And it is always be used for engraving various materials, such as wood, Acrylic, PVC board, MDF, marble, rubber board, plastics, glass, and foams, crystal, etc.

In this post, we will take a look at how to calibrate the tool magazine for the second situation. This tutorial applies to automatic tool changer cnc with the WEIHONG system NC60A.

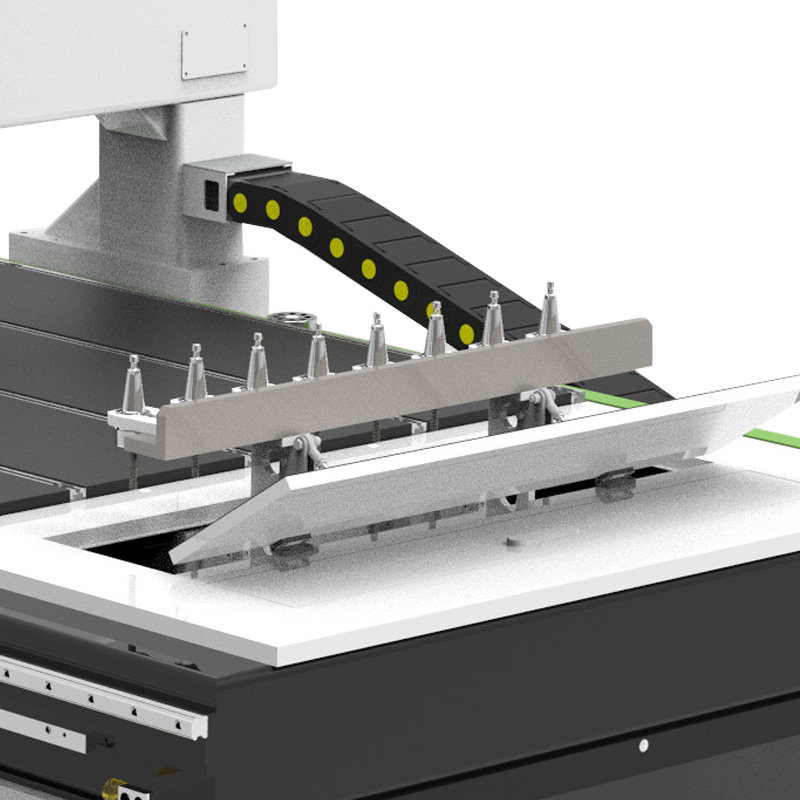

Tool Number Introduction

Before we dive into the specifics, let us first understand the tool number corresponding to each tool finger. When we face the tool magazine, the tool numbers are T1, T2, T3, T4, T5, and T6 from left to right.

Tool Bank Calibration Method

Manually run the automatic tool changer cnc router with the handwheel (MPG), place the T1 tool in its corresponding tool finger, and then write down the actual mechanical coordinates of XYZ in the WEIHONG system. For example, they are 313.500mm, 3746.890mm, and -274.000mm. Next, we save the three coordinate values for the T1 tool in the WEIHONG system. Analogically, we can calibrate T2~T6 tools.

Save the Actual Mechanical Coordinates in the WEIHONG Program

Let's take a closer look at the process step by step.

In the WEIHONG program of your ATC Router, click the icon with the three horizontal lines in the upper right corner of the screen, and a popup window will come out.

Move the cursor to the option-Technician Interface, and click it.

The password dialog box pops up. The password is ncstudio; input it and click confirm.

Click the icon-System on the top.

Move the cursor to the option-GlobalParameters and click it.

In the popup, we click the icon on the lower left and select Manufact.

Click Overview, and click Tool.

Scroll down the menu until you see Tool Machine Coordinate.

Double-click the corresponding row to modify the coordinate value, enter the actual values, and click OK to save. Complete!