Views: 16 Author: Site Editor Publish Time: 2021-09-14 Origin: Site

With the increasing technological innovation, more and more industries are demanding CNC Plasma Cutter as a great addition to their business. This computer-controlled device can create intricate as well as complex patterns on the surface of the material. The ability to cut and carve so precisely, cnc plasma cutter with servo motor create a prototype of the objects.

CNC Plasma Cutter is used to cut a variety of materials very efficiently but it does not come without any hazards. It is extremely important to keep one’s head out while operating this CNC plasma cutting machine.

1、Wear Plasma Helmet or Mask

2、Protect Yourself and Others

3、Welding Gloves to Protect Your Hands

4、Cover Your Legs While Operating the Machine

5、Laced and Tied Boots To Protect Your Feet from Both Sparks and Dropping Pieces of Metal

6、Fire Extinguisher

7、Proper Ventilation

Features of CNC Plasma Cutter:

(1)Max cutting speed can reach to 10m per minute while precision keep withnin 0.3mm.

(2)Less and tidy incision ,no cutting slag or need of after treatment.

(3)High configuration for numerical control system ,stable performance.Automatic arc striking can reach to 99% success rate.

(4)Adopting swift clamp to avoid workpiece moving and greatly reduce the cost.

Advantage of cnc plasma cutter machine:

1. Plasma power

Hypertherm 200A power

Famous brand all of the world, low price, Cutting thickness 0.3-52mm

2. Controller system

Beijing Start control system,

configured 7-inch high-resolution true color LCD display. can be dynamically cut graphics running track.

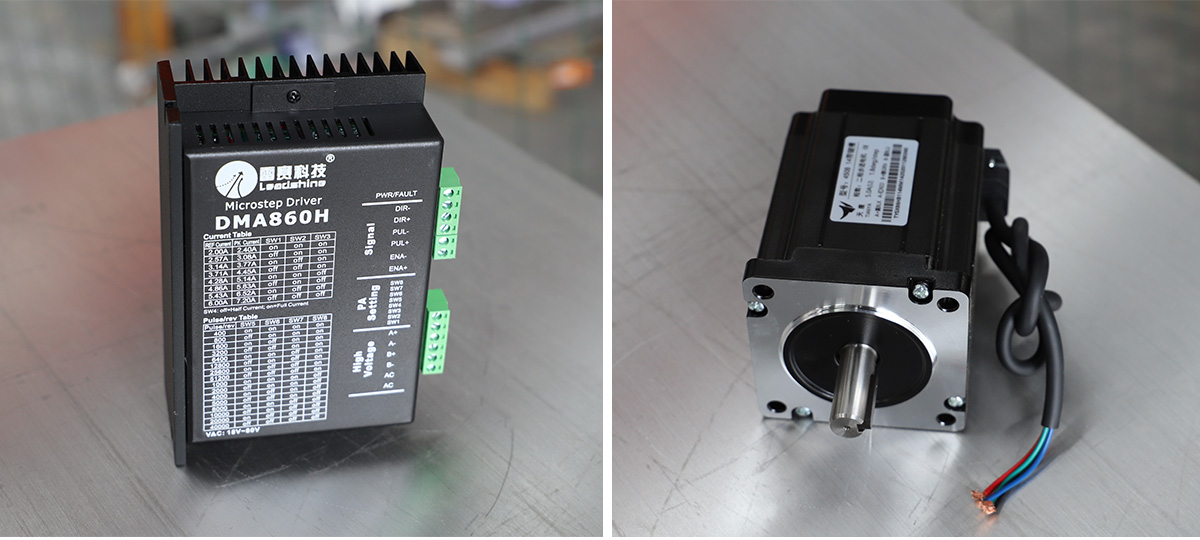

3. Motor

450B stepper motors

With high quality & stronger power, ensure machine work very well.

4. Driver

Leadshine 860H Drivers

It can run with smaller noise, lower heating, smoother movement and have better performances at higher speed.Save human strength and save time.

5. Automatic Arc Pressure adjustable

Beijing Start

Adjust the torch height during cutting. Perforated height self-positioning

6. software Fast Cam

nesting software for machine. Using it, and finally export G code, then can be recognized by machine

Sawtooth worktable

Loading roller

High-end drive system

Scrap push-pull box for easy cleaning

Parameter Configuration

| Description | Parameters |

|---|---|

| Working area | 1300x2500mm |

| Machine Body | Thickened Square Tube Welding Body |

| Worktable | Sawtooth |

| Reducer | Japan SHIMPO |

| Control System | STARFIRE with THC |

| Plasma Power | HUAYUAN |

| Lubrication | Automatic |

| Transmission | X,Y-helical rack pinion, Z ball screw |

| Drive system | Japan servo motor and drivers |

| Power | 63A/ 100A/120A/160A/200A |

| Cutting Torch Path | ≤200mm |

| Positioning Accuracy | 0.2mm |

| X, Y Axis Resolution | 0.1mm |

| Working Voltage | 380V/50Hz |

The machine plasma torch (cutting torch) has cutting and hole-cutting functions, fast cutting speed, strong cutting ability, high surface quality, smooth cut surface, good durability of consumable parts, reducing production costs and improving production efficiency. Suitable for cutting all kinds of metal materials such as low carbon steel, alloy steel, non-ferrous metals.

Famous brand motor and driver, excellent performance, stable and reliable quality. Using Japanese new design, new technology and high-quality materials, it has greater torque, lower heat generation, low vibration, smooth operation, and good anti-interference ability.