Views: 11 Author: Site Editor Publish Time: 2021-09-30 Origin: Site

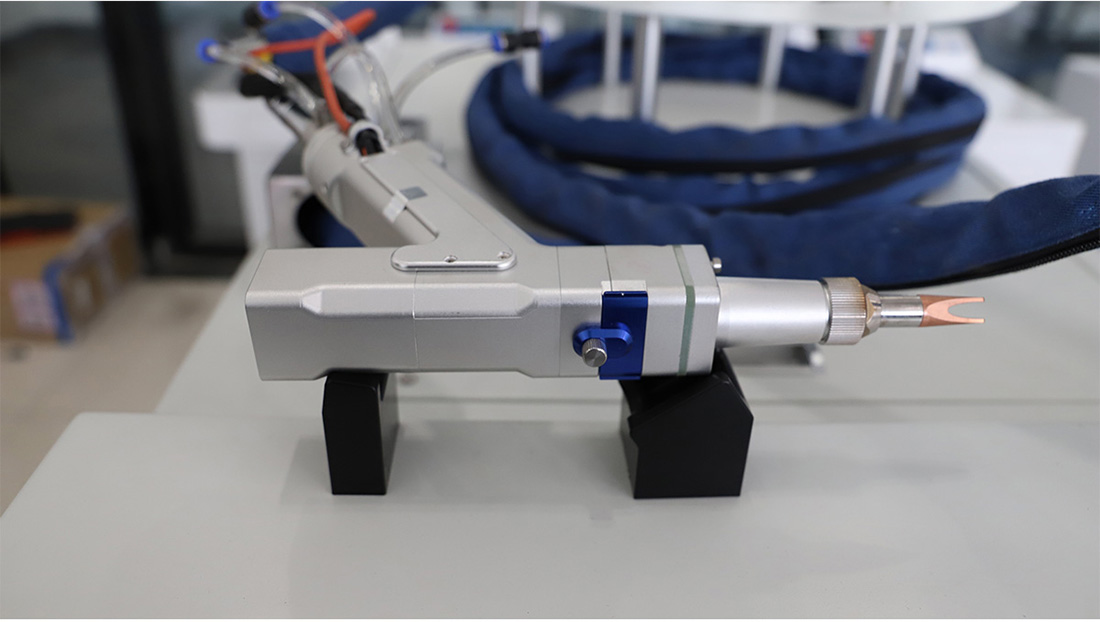

IGOLDENCNC Handheld Laser Welding Machine, also called Handheld Fiber Laser Welder, Portable Fiber Laser Welding Machine, Manual Fiber Laser Welding Machine, is a new type high-power, high-end continuous welding tool that couples a high-energy laser beam into an optical fiber, collimates it into parallel light through a collimating lens after long-distance transmission, and then focuses on the workpiece for welding.

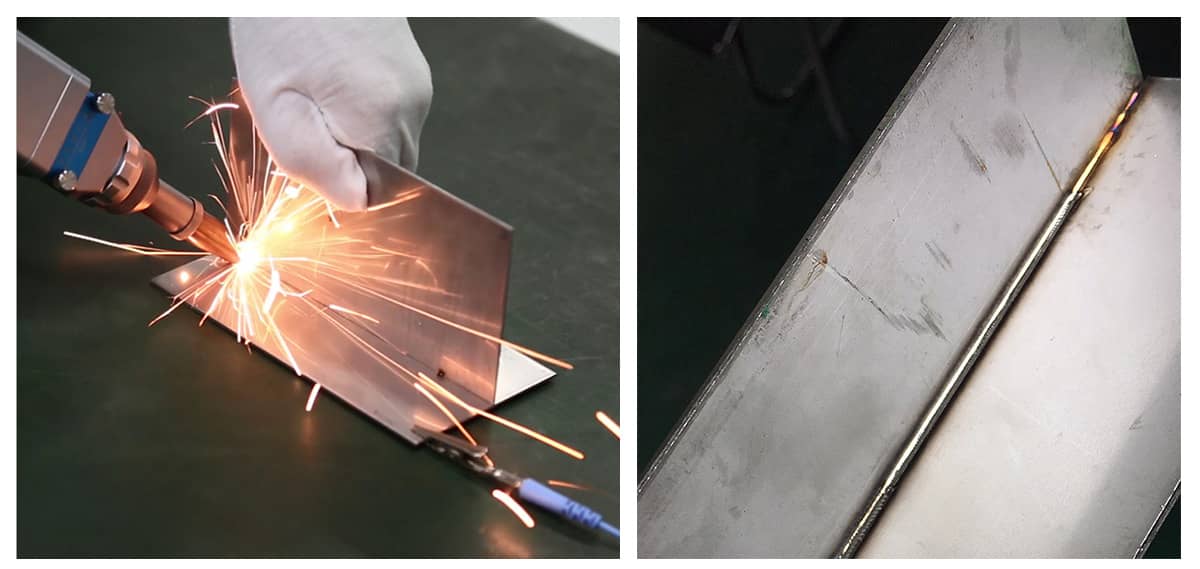

The handheld laser welding machines for metals, equipped either with an independently developed wobble welding head or a common welding head, greatly improving the joint strength and quality of welding and obtaining better weld formability. All products realize spot welding, straight seam welding, overlap welding, circumferential welding and welding of any track. And you can also add welding wire. Compared with traditional argon arc welding, the efficiency is increased by more than 50%.

Replacing the old thermal welding systems with a hand-held type weld gun, not only facilitates the welding of molds, advertising characters, kitchen utensils, doors and windows, etc., but also makes laser welding possible in outdoor operations, the welding ability expands from small light workpieces to large bulky objects that are difficult to move, such as stainless steel silos, stainless steel spiral air ducts, chimney pipes, auto steel pig feeders, almost no size limitations, which indicates that the traditional welding of electric welding, argon arc welding, etc. will definitively be replaced by fiber laser welding.

Laser Welding Machine has the advantages of simple operation, beautiful weld seam, fast welding speed, and no consumables. It can be used for welding various metals sheets and tubes: such as stainless steel plates, iron plates, galvanized plates and CS plates, aluminum plates, brass plates, other metal sheets and tubes.

Laser Welding Machine Configuration

1) High Efficiency

The welding speed of laser welding machine is twice of traditional welding method.

2) High Quality

The weld seam is smooth. There is no need to polish the weld seam, saving time and manpower.

3) Low Cost

80% to 90% power savings, processing costs are reduced by 30%.

4) Flexible Operation

Can operate it without experience.

Typical fields of application are:

Mould and tool construction / repair

Thin sheet / precious steel production

Repair in machine construction – turbine blades, machine components, housings

Medical technology – medical part welding and production

Sensor production (micro-welding, sheath tube cutting and scribing)

Precision Engineering

Dental Laboratories

Jewellery Repair and Production

Strong arguments

Bullet

Significant cost savings

in the entire sheet metal processing process due to less rework and the use of lower sheet thicknesses.

Bullet

More business

especially when the best optics and highest quality are required, you have all the trumps in your hand with our hand-held laser technology.

Bullet

Better employee satisfaction

because simple welding work such as tacking parts can be handed over to unskilled workers at short notice, without any lead time.