Views: 19 Author: Site Editor Publish Time: 2021-12-14 Origin: Site

Reasons for common mechanical failures of 1325 atc cnc router : Among the common failures of cnc wood router, mechanical failures often have obvious characteristics.

1. The wood machine tool spindle orientation position is not accurate, but the machine tool does not give an alarm. Possible reason: Due to the current machine tools, the spindle orientation generally adopts the encoder orientation method, and the spindle and the spindle motor adopt a 1:1 connection, and the motor's built-in encoder is directly used for orientation. Therefore, this situation must be a problem with the mechanical connection part!

2. The positioning accuracy varies from time to time, and the machine tool does not alarm: possible cause: the mechanical transmission chain is not well connected. Such as loose couplings.

3. The load of the wood machine tool is too heavy: current alarms often occur, and the motor generates abnormal heat. Possible cause: poor mechanical assembly, resulting in heavy mechanical load. For newly designed machine tools, this phenomenon may also occur if the servo motor is selected too small. In addition, this alarm will occur if the servo parameter setting is wrong.

4. For wood machine tool auxiliary actions, such as tool change action, the output signal to control the action has been available, but the tool change action has not been completed. Possible causes: mechanical jam, pipeline blockage, etc.

Note: When the machine tool fails, the machine and electricity are often intertwined. Because the mechanical part has relevant training, it will not be described here

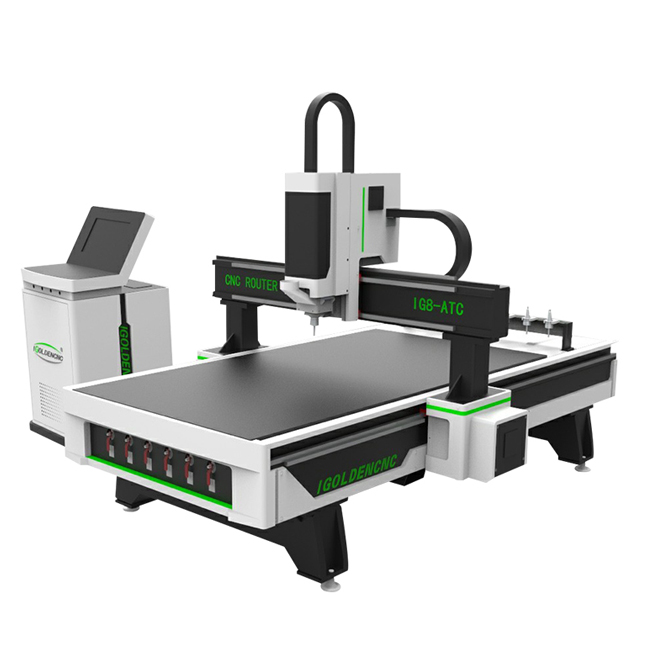

1. Heavy-duty welded frame and gantry ensures ATC CNC Wood Router suitable for a long time and efficient woodworking;

2. Multi-head or spindle machines can change 2 or 3 or 4 tools when process different kinds of raw materials, but automatic wood carving machine can change more than 8 types of tools automatically according to the different knife functions in the engraving process;

3. If you want to do 3D objects or molds or more complex steps, the spindle is required to swing 180 degrees. Please refer to a 4 Axis CNC router;

4. Please notice that all the specifications can be made and designed to follow your own situation;

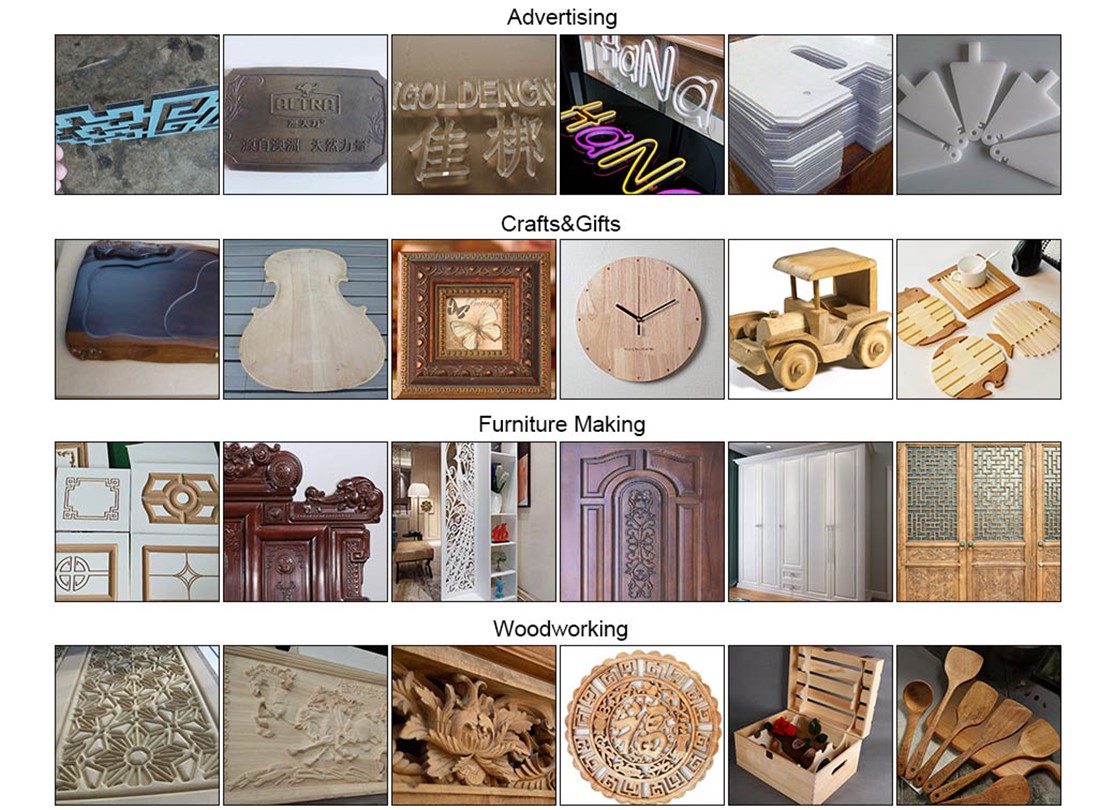

1325 atc cnc router application:

* Furniture: wooden doors, cabinets, plate, office and wood furniture, tables, chair, doors and windows.

* The wood products: voice box, game cabinets, computer tables, sewing machines table, instruments.

* Plate processing: insulation part, plastic chemical components, PCB, inner body of car, bowling tracks, stairs, anti-Bate board, epoxy resin, ABS, PP, PE, PEHD and other carbon mixed compounds.

* Decorate industry: Acrylic, PVC,MDF, artificial stone, organic glass, plastic and soft metals such as copper, aluminum plate engraving and milling process.

With Japan Yaskarwa servo motor 850w and driver and Delta 11kw inverter with HQD or HSD9.0kw auto tool changer ATC 0-24000rpm/min air cooling spindle 1325 1530 2030 auto tool changer cnc router machine for woodworking.