Views: 15 Author: Site Editor Publish Time: 2021-08-24 Origin: Site

If you are looking for the best Fiber Laser Cutting Machines in 2021 for metal sheet processing, igoldencnc H series would be an ideal solution. It is the best laser cutter out there that works fine with cutting stainless steel, carbon steel, galvanized sheet, copper, aluminum, gold, silver etc. Customized version and free sample available for this machine to meet any requirement from the customer end. H series covers both the beginner-friendly solution and comprehensive solution according to different applications. The power of the best laser cutting machine ranges from 1000w to 10000watt and qualified presale and after sale service team is available 24 hours/7 days. The best laser cutting machine application industry fields include rail locomotive, aerospace, automotive parts manufacturing, car body processing, bogie manufacturing, and precision medical beauty equipment processing, steel and wood furniture, machinery manufacturing, household appliances, kitchenware, fitness equipment manufacturing, Laser cutter plays an important role in wherever metal materials need to be cut.Price:60000-70000$

●High efficiency: high-speed digital motion control by Germany technology system, especially for high-speed, high-precision laser cutting.

●Integrated design: a 10% reduction of the volume of space, easier and cheaper for ocean and inland transportation.

●Stable running: adopting gantry structure with synchronous bilateral gear and rack drive, and high-strength aluminum beams enhance its stability.

●Low energy consumption: Photoelectric conversion rates as high as 25-30% which can save energy and power. Electric power consumption for this type fiber cutting machine is only about 20%-30% of the traditional Co2 laser cutting machine.

●High technology:full application of laser technology, mechanical technology, numerical control technology and other advanced technology.

Fiber Laser Cutting Machines Applicable Fields

Applicable for high-speed cutting on various metal plates or tubes such as S/S, carbon steel, galvanized sheet, electrolytic plate, aluminum plate, steel, brass, alloy plate, rare metals and other materials;

Widely used

Widely used in kitchen appliance, electric control box, high-resolute device, mechanical equipment, electrical equipment, lighting, posters, auto parts, display equipment, hardware and metal processing.

Top 5 Advantages of a High Power Laser Cutting Machine

When we were looking for ways to enhance our laser cutting capabilities we made a list of the advantages we could see from going to a fiber machine. It turned out to be a long list. To avoid boring you with detail, here, in reverse order, are the top 5 advantages we identified.

1. Better material utilization and tighter nesting, thanks to narrower kerf and less distortion due to workpiece expansion.

2. Cut thicker sheet and plate material. With this laser, we can cut mild steel up to 0.312” thick and stainless and aluminum up to 1” thick.

3. Faster piercing and cutting. Higher power and a smaller spot size mean a fiber laser “punches” through in less time. On a job where there are a lot of holes to cut that can lead to big time savings. Plus, faster melting allows higher traverse speeds. That’s even more time saved.

4. Cut reflective materials like aluminum and copper. Cutting these with a CO2 laser meant going very slowly because they reflected most of the laser energy. The shorter wavelength of fiber means we can cut these at a speed that’s high enough to be useful.

5. Better cut edge quality. This is primarily a result of higher power and air assist, but laser beam geometry and workpiece thermal conductivity contribute too. The thinner beam keeps the energy more tightly focused, and that means a sharper edge. In addition, by putting less heat into the metal there’s less distortion.

Parameter Configuration

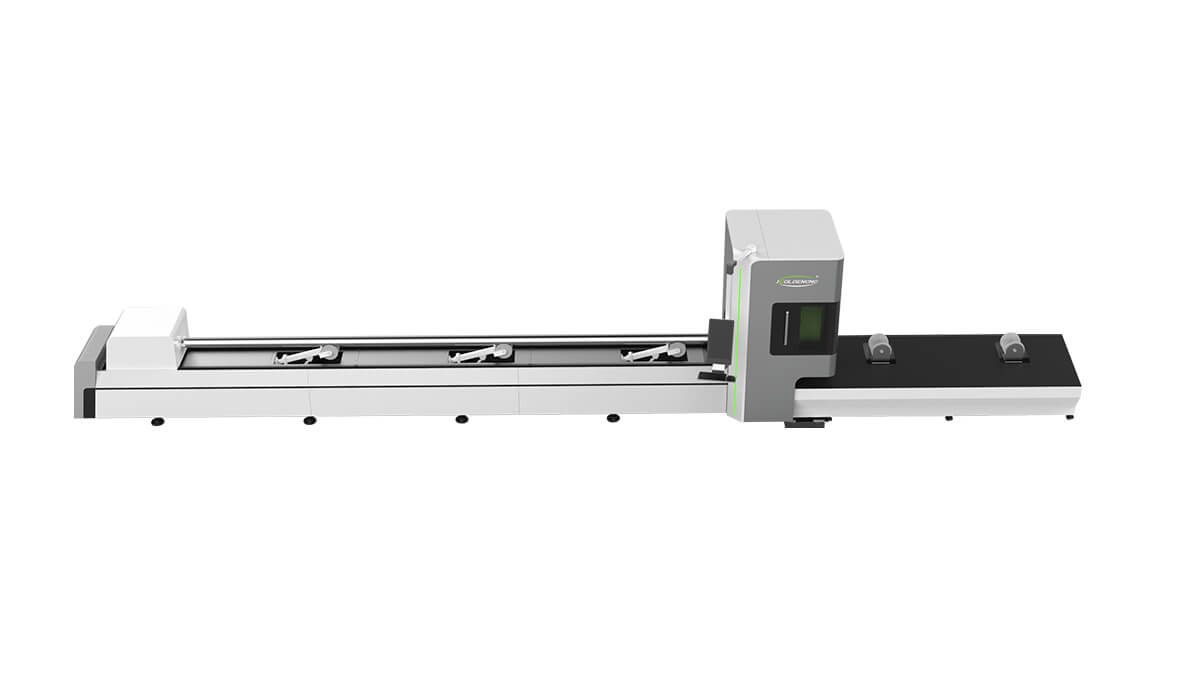

Model | IGR-T |

Chuck | ①240 front and rear dual pneumatic chucks; ②Range of clamping pipe diameter: 20mm-240mm; ③Transmission mode: gear transmission; ④Rated speed: about 80r/min; (For round pipes according to the outer diameter, for rectangular pipes according to the largest diagonal) |

Bed | Tube welded bed |

Motor | Yaskawa Servo Motor |

Reducer | SHIMPO Reducer |

Rail | TaiWan HIWIN |

Rack | T-WIN helical gear |

Y-axis travel | ≈7m, applicable tube length ≤6m |

X-axis travel | 240mm |

Z-axis travel | 220mm |

Support form | Pneumatic variable diameter wheel support |

Rated travel speed | Y-axis about 40m/min, XZ-axis about 30m/min |

Dimensions | 12.5m(L)×2.15m(W)×2.5m(H) |

System | Cypcut Laser cutting system |

Laser head | RayTools BM109 |

Laser | Raycus 1.5KW |

Operation console | Industrial computer + touch screen |

PRECISION CUTTING

LX3015 series coperate with raytools cutting head ,The error is less than 0.01mm,you can choose RAYTOOLS/ AU3TECH/WSX/PRECITEC as well ,we coperate with top brand to ensure quality.

2T STABLE MACHINE FRAME

Palte welded machine bed can support heavy material cutting and no deformation within 10 years ,and It doesn't shake when cutting, so as to reduce the error.the weight of machine bed 3000x1500 about 2T

BOCHU +CYPCUT CONTROL SYSTEM

Easy to learn and easy to operate ,this can accurately control the operation of the cutting head to maximize the utilization of materials and reduce tailing ,FSCUT 2000 and others optional ,plaese choose according to seller's advice