Views: 13 Author: Site Editor Publish Time: 2021-09-24 Origin: Site

CNC Plasma Cutter are widely used to cut thin metal sheets, square and round metal pipes, including iron, cold rolled steel, hot rolled steel, stainless steel, galvanized steel, carbon steel, copper, brass, alloys, bronze, aluminum, titanium. Plasma cutting machines are widely used in machine tool manufacturing, petrochemical equipment, light industry machinery, pressure vessels, shipbuilding, mining machinery, electricity, bridge construction, aerospace, steel structure and other industries, suitable for amateurs, family workshops, family business, Small workshops, small workshops and other industries, business, school education, industrial manufacturing.CN¥34,254.32-CN¥35,580.18

1,High strength machine tool annealed by exclusive high temperature numerical control electric furnace to ensure a long-term stability and accuracy.

2,Lateral sliding door is design to supply a better human-computer interaction and save the room.

3,Imported original fiber laser generator which generates high-quality laser beam and shows stable performance without reflection lens,optical path adjustment,and machine maintenance.

4,The fiber laser generator provides high-efficiency of electro-optical conversion(Could reach 30%),which reduces a lot of power consumption and production costs.

5,Imported servo motor and gearing system to guarantee precise cutting.

6,Dedicated software enables graphic or test to instantly designed or processed.

7,Automatic interchange table for shortening the time of loading and unloading the material.

8,Smooth and fine edge or surface and small distortion.

9,Very low power consumption (Only 1/3 to 1/5 of the YAG with the same power) and high cutting speed (Treble the YAG with the same power) .

10,No gas is needed. Auxiliary gas could be blow for cutting the metal plates.

11,High cutting speed and low operation costs. Fast return on investment

Maintenance of CNC Plasma Cutter machine

1. Assemble the cutting torch correctly

Install the cutting torch correctly and carefully to ensure that all parts work well together and that gas and cooling gas flow. Installation Place all parts on clean flannelette to avoid dirt sticking to the parts. Add appropriate lubricating oil on the O-ring, and make the O-ring brighter. Do not add more.

2. The consumable parts should be replaced in time before they are completely damaged

Do not replace the consumable after it is completely damaged, because the severely worn electrode, nozzle and vortex ring will produce uncontrollable plasma arc, which can easily cause serious damage to the cutting torch. So when the first time found cutting quality decline, you should check the consumption in time.

3. Clean connecting thread of cutting torch

During replacement of consumable parts or daily maintenance inspection, ensure that the internal and external threads of the cutting torch are clean. If necessary, clean or repair the connection threads.

4. Clean the contact area between electrode and nozzle

In many cutting torches, the contact surface of the nozzle and electrode is a charged contact surface. If there is dirt on these contact surfaces, the cutting torch will not work properly and should be cleaned with hydrogen peroxide cleaning agent.

5. Check gas and cooling gas daily

Check the flow and pressure of gas and cooling air every day. If the flow is found to be insufficient or leaking, the machine should be shut down immediately to troubleshoot.

Advantages of CNC Plasma Cutter:

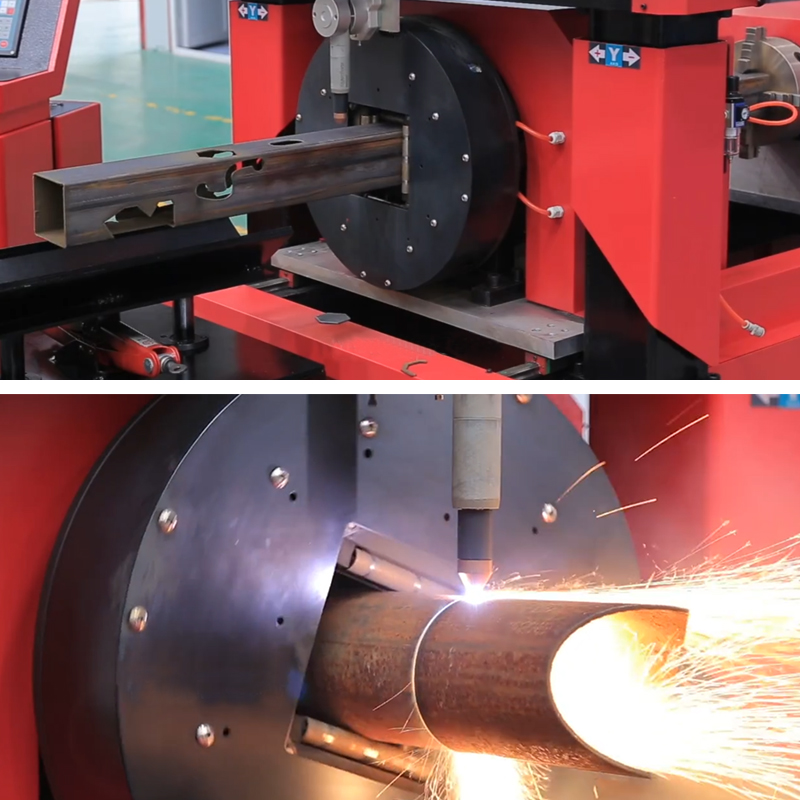

The new flat tube integrated plasma cutting machine, this machine has a reasonable technical concept

Customers can improve their performance while saving costs and meeting the processing needs of metal processing companies and other equipment companies

Cutting metal plates and tubes can be used on one machine to better reduce customer procurement costs

Application of plasma pipe bevel cutting machine

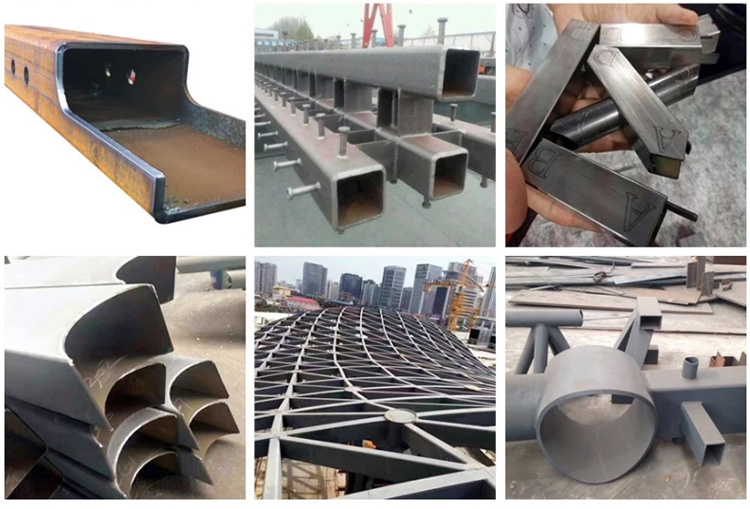

plasma pipe bevel cutting machine is specially designed for cutting beams, including H beam, I shaped beam, angle steel, channel steel and square pipe etc. It can cut stainless steel, carbon steel, aluminum, and other non ferrous metals.

It's widely used in steel structure construction, shipbuilding, bridge fabrication, rail way, marine engineering, web structure, building walls, towers and mechanical engineering industries, etc.

CNC Plasma Cutter Application