Views: 10 Author: Site Editor Publish Time: 2021-12-24 Origin: Site

The pipe laser cutting machine is the most widely used processing machine in the laser processing industry. The whole machine is stable and reliable, with good dynamic performance and strong load capacity. It is a high-tech product integrating laser cutting, precision machinery, and CNC technology. The pipe laser cutting, as the name implies, this type of machine can be used for both sheet cutting and pipe cutting. It realizes a dual-purpose machine, greatly improves work efficiency, reduces the cost of purchasing equipment, and saves money between the two machines. The trouble of switching back and forth between work is both convenient and efficient.

1. The pipe laser cutting machine has high precision

Traditional pipes are cut manually, so each cut part is different, while laser processing uses the same fixture system, and the processing design link is directly completed by the programming software, and the processing can be completed in one process with high precision. In modern manufacturing, the accuracy of laser cnc laser pipe cutting machine has become one of the most important criteria for measuring laser cutting, and laser cutting is currently a more accurate cutting processing mode.

2. The pipe laser cutting machine is fast

The laser can cut several meters of pipe in one minute, and the efficiency is hundreds of times that of the traditional manual cutting method. This means that the laser pipe cutting machine has an efficiency that is difficult to compare with the traditional processing method.

3. The flexibility of laser pipe cutting machine

The laser of the pipe cutting laser can flexibly process various shapes, and designers can carry out complex designs, which is unimaginable under traditional processing methods.

4. Batch processing of pipe laser cutting machine

The standard pipe length is 6 meters. The traditional processing method needs to be applied to a rather bulky fixture device. The laser processing of the laser pipe cutting machine can easily complete the clamping and positioning of several meters long pipes, and the feasibility of batch processing is also higher.

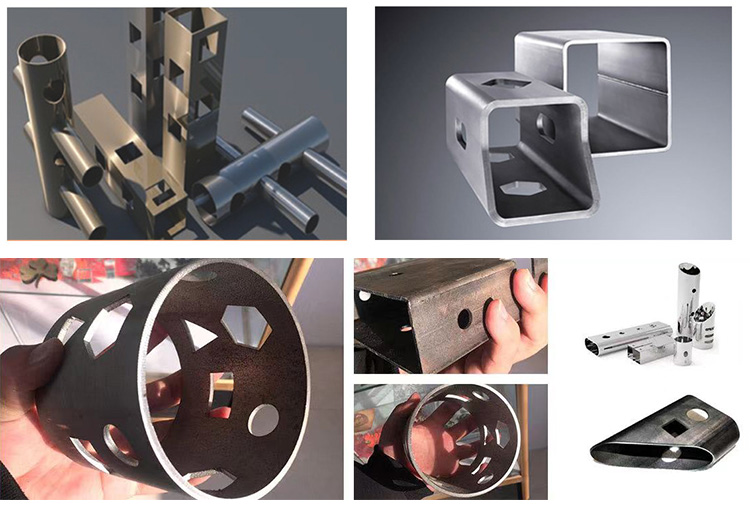

In the actual processing process, many users, in addition to the standard round tube cutting, there are also many special-shaped tube cutting. There are also many users who are always worried about whether the laser pipe cutting machine can cut the special-shaped tube. This is completely unnecessary worry, because at the beginning of the design of the pipe cutting machine, metal pipes of different sizes and specifications have been considered. It uses an electric clamping chuck, which can automatically clamp square tubes, round pipes and special-shaped pipes of different specifications and types. The scope of cutting is more extensive.

When to Use pipe laser cutting machine

Knowing when to use laser tube cutting is important. If pieces of tube need to be welded at a later stage in manufacturing, a laser tube cutter offers the best solution.

Laser tube cutting is precise, so it works well when precise and clean welding of pieces is needed.

For tubes that need to be bent before welding, laser tube cutting offers the cuts you need. The cuts allow tubes to be manually bent. It reduces the number of parts needed as well as the amount of welding you'll have to do.

Which fabrication work makes laser cutting meeting its boundaries?

While pipe laser cutting machinemay provide a fast, versatile and accurate way to cut pipe, flat plate and sheet, there are limitations:

Laser cutting is typically used for thinner materials, although some machine configurations can cut pipes up to 32 mm thickness.

Laser cutting is typically used for cutting without bevels. Consequently, many laser cutting machines either do not have bevel cutting capabilities or the capability is not a primary focus.

Laser cutting machines are extremely expensive, making the investment high enough so that running only one production shift is not nearly enough for fabricators to realize a speedy return on their investment (ROI).

Laser cutting machines are becoming more and more common and there are more and more job shops with laser cutting machines in any given manufacturing area. Consequently, the market is becoming more competitive, resulting in lower outsourcing costs, which in-turn makes the return on any purchase investment that much more difficult to pay back.

Laser cutting machine costs are relatively high because of the following:

High costs to purchase the laser cutting machine.

Higher energy consumption.

Higher operating costs.

While productivity on thinner materials may be extremely high, laser cutting becomes less effective as the material thickness increases.

Laser cutting machinery typically requires personnel with a higher level of technical and professional capability to perform maintenance work that is typically more complex.

Parameter Configuration

Model | IGR-T |

Chuck | ①240 front and rear dual pneumatic chucks; ②Range of clamping pipe diameter: 20mm-240mm; ③Transmission mode: gear transmission; ④Rated speed: about 80r/min; (For round pipes according to the outer diameter, for rectangular pipes according to the largest diagonal) |

Bed | Tube welded bed |

Motor | Yaskawa Servo Motor |

Reducer | SHIMPO Reducer |

Rail | TaiWan HIWIN |

Rack | T-WIN helical gear |

Y-axis travel | ≈7m, applicable tube length ≤6m |

X-axis travel | 240mm |

Z-axis travel | 220mm |

Support form | Pneumatic variable diameter wheel support |

Rated travel speed | Y-axis about 40m/min, XZ-axis about 30m/min |

Dimensions | 12.5m(L)×2.15m(W)×2.5m(H) |

System | Cypcut Laser cutting system |

Laser head | RayTools BM109 |

Laser | Raycus 1.5KW |

Operation console | Industrial computer + touch screen |

Scope of Application