Views: 7 Author: Site Editor Publish Time: 2022-05-26 Origin: Site

As a brand-new automatic processing machine, the multifunctional automatic furniture woodworking cutting machine greatly improves the production efficiency and production quality in terms of carving accuracy and carving speed. However, as a new type of mechanical equipment, there are still very few operators who are really proficient in the automatic furniture woodworking cutting machine, and many people simply use the cabinet door carving machine. Therefore, many users tend to ignore the operation requirements of the furniture woodworking automatic cutting machine, such as the preparations before starting the cutting machine, the instructions for the use of the cutting machine, and the cleaning work after the furniture woodworking automatic cutting machine, etc. opened. Today, I will focus on the cutting machine and the preparations before starting.

1. The operator must be familiar with the performance, processing range and precision of the machine tool according to the manual of the automatic furniture woodworking cutting machine, and must master the function and operation method of the machine tool and its numerical control device or computer.

1. Check that each switch, knob and handle is in the correct position.

3. Start the control electrical part and preheat according to the regulations.

4. Start the automatic furniture woodworking cutting machine to make it run dry, check the sensitivity of each switch, button, knob, handle and whether the lubrication system is normal.

5. Familiar with the processing path and workpiece origin of the workpiece to be processed.

Only by being proficient in the performance of the Cutting Machine Woodworking Tools and familiar with the operation steps of the engraving machine, can the woodworking cutting machine be used better.

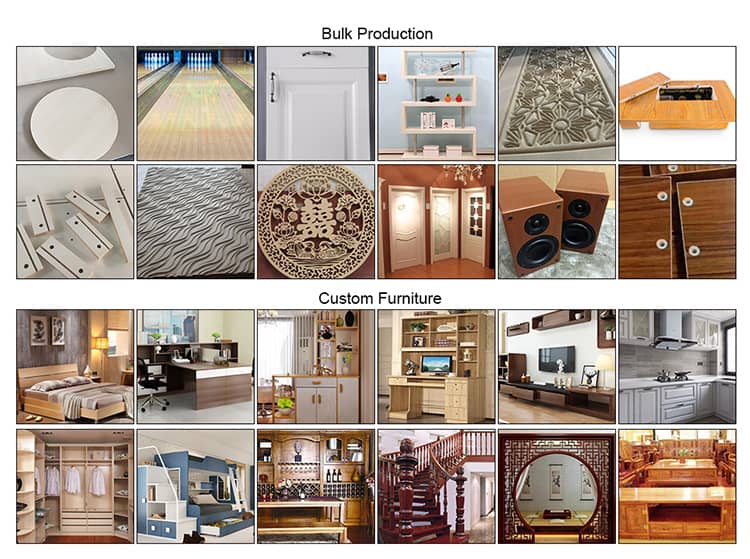

Fully automatic furniture woodworking cutting machine, equipped with 9.0kw air-cooled spindle, can choose two tool changing methods: straight row tool change and disc tool change. Usually used in conjunction with labelling machines and automatic loading and unloading platforms. Fast, high precision, efficient and stable. It is suitable for the processing of various cabinet doors and wooden doors. The material is cut, punched, slotted, and pushed into one; the utilization rate of the plate is as high as 98%, which saves the material cost; the heavy industry quality, stable operation for ten years; easy to operate, quickly remove obstacles, and conducive to learning.

(1) Optimize cutting, punching, grooving, perfect integration, uninterrupted process, maximize efficiency and output, strong compatibility, and can be seamlessly connected with a variety of ticket distribution software;

(2) Adopt 200×250 thick-walled square tube support structure, engineering aesthetic appearance design structure, tempering or vibration vector effect processing, imported pentahedron metal processing center for high-precision milling;

(3) The side-mounted design structure with three flange sliders on one side is adopted, and the operation is stable. The rack guide rail design structure is completely dustproof, and the guide rail adopts a segmented structure, so it is more convenient to replace the guide rail without professionals;

(4) Numerical control system, stable performance and simple operation. Ordinary people do not need professional knowledge, and can complete the operation through simple training;

(5) The double-layer hollow vacuum adsorption table can adsorb plates of different sizes, and the minimum cutting plate can reach 25mm;

(6) The four-direction six-action automatic plate positioning system is adopted, and the plate positioning is faster and more accurate. Cooperate with the automatic detection system of the plate feeding position to effectively prevent various unexpected situations that may occur during the plate feeding process;

(7) Matching with the central intelligent dust removal system can ensure that the particulate waste in each link and part is effectively cleaned and collected, and can effectively ensure the continuity of the cutting work;

(8) Equipped with a central automatic lubrication system and set up regular automatic oil injection to ensure the efficient operation of the machine;