| Availability: | |

|---|---|

CNC Wood Cutting CNC Woodworking Machine Description:

MDF Plywood Wood Cutting Machine is good at heavy-duty and complex 3d wood Cutting & Carving of wood panel, MDF, Polywood, etc. All the working areas and specifications can be customized according to your requests. Double platform MDF and plywood board cutting CNC Router machine is a multi-function automatic CNC nesting machine, which integrates cutting, chamfering, relief, ollowing, punching, slotting and other processes, while eeting the processing requirements of cabinet doors and cabinets.

CNC Wood Cutting CNC Woodworking Machine Features :

1. The lathe bed adopts strong welded steel tube to avoid distortion.

2. Y axis adopts double motors to keep stable moving.

3. Z axis adopts ball screw transmission to ensure high precision machining.

4. High accuracy rack rail travel method with high speed.

5. HIWIN square guide rail with high accuracy and heavy burthen.

6. Advanced international technology vacuum with double cavity.

7. Humanization design of lathe bed vacuum and easy working.

8. Intelligent protecting working fable.

9. The rotary device can do 3D woodworking on cylinders.

CNC Board Cutting Machine Parameter

| Model | iGC-4AP-1325 |

| Machine stroke | 1300*2500*200mm*2 stations |

| File format | G code |

| Workbench structure | Class A hard special vacuum adsorption table |

| Working voltage | 380V/50HZ |

| Bed | Heavy-duty stable bed, CNC gantry milling |

| Spindle | HQD 6KW air-cooled tool change spindles*2, 4.5KW tool change spindle*2 |

| Drive system | Server motor drive |

| Control system | LNC system + wireless handwheel |

| Rack | High precision helical rack |

| Guide rail | HIWIN square rail |

| Lead screw | TBI lead screw |

| Inverter | Fuling |

| Cabinet | Independent large computer cabinet |

| Dust collection system | Floating dust collection + central dust collection structure |

| Lubrication system | Electric motor oil pump microcomputer centralized lubrication control, regular and quantitative lubrication |

Advantage Of Cnc Mdf Cutting Machine:

Flawless Cutting Accuracy

With its computerized control, a CNC machine can produce multiple identical pieces. It can also produce one-off pieces that conform precisely to programming coordinates. This accuracy saves companies money by reducing waste pieces.

Excels at Intricate Design

CNC machines can execute intricate designs that manual machines can’t. CNC millers and routers routinely perform intricate millwork and cutouts for furniture. In years past, this work was by hand and reserved for premium products. Today, computer controlled machines make it widely available.

Fast Training Process

Due to the physical nature of the operator’s job, a manual woodworking machine can take years to master. Conversely, computer controlled machinery can be mastered in as little as weeks. A CNC machine operator controls its computer, oversees the production process, and performs light servicing – tasks that can be learned through training as easily as through experience.

Excellent Resale Value

As long as it is well maintained, industrial grade CNC machinery retains its value well. With woodworkers constantly on the lookout for quality used machinery, you shouldn’t have difficulty liquidating a machine when you need to upgrade to a new one.

Wood Board Cutting Machine Detail

| Seamless connection of four processes, multiple processes without manual tool changes |

| HQD air-cooled tool change spindles, 6KW*2+4.5KW *2; Cooperating with the cutting machine, it can only be driven to realize 0 second tool change and higher efficiency production |

| Double-station table, you can unload and cut at the same time, improve work efficiency |

| Feeding roller to increase the feeding speed |

| Class A hard double-layer vacuum adsorption table |

| High precision rack + HINWIN guide rail |

| Independent large computer cabinet LNC system + wireless handwheel |

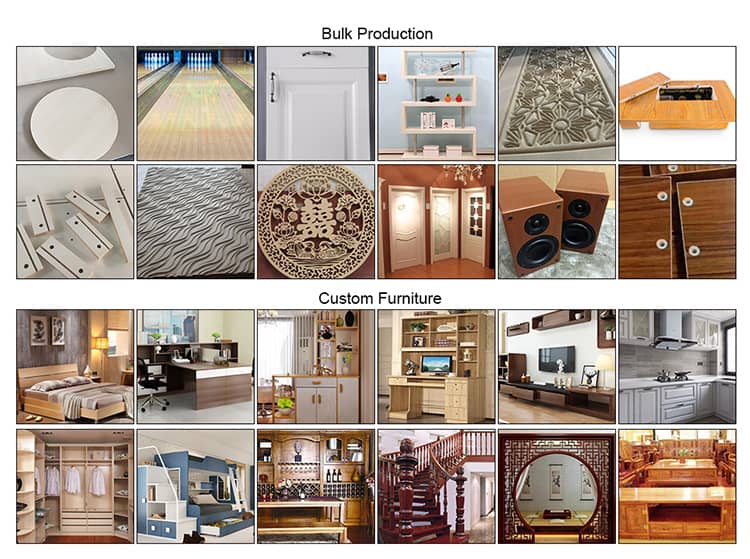

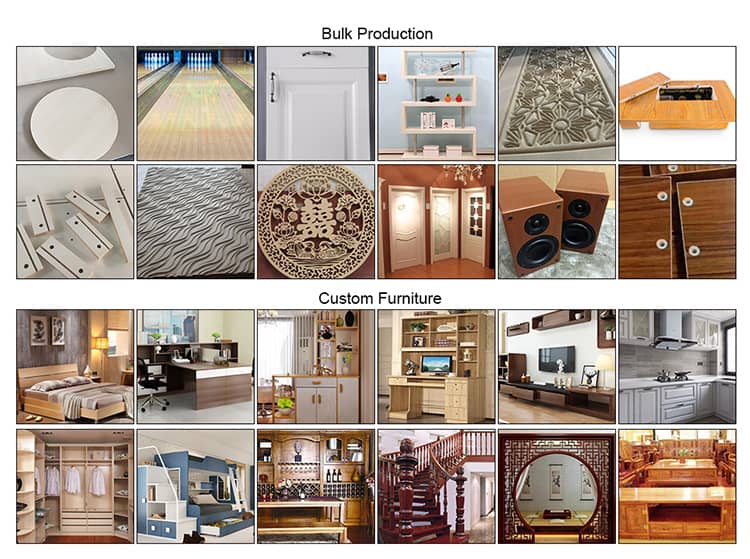

CNC Wood Cutter Machine Sample

The most advanced, multi-function ATC Nesting CNC machine with drilling bank, perfect for professional scaled furniture manufacturers, designed by iGOLDENCNC for changing tools automatically while working, combined with a competitive set of configurations.

Hot applications include:

>Furniture industry: panel furniture, cabinets, sliding doors, soft bags, office furniture, wooden doors, whole house customization, etc.

>Wooden products: speakers, game cabinets, computer tables, sewing machine tables, musical instruments;

>Sheet metal processing: insulation parts, plasticized workpieces; pcb; inner body of motor vehicles, bowling track; carbonized mixtures such as anti-fold special board, epoxy resin, abs, pp, pe;

>Decoration industry: engraving and cutting of acrylic, PVC, MDF, plexiglass, plastic, and copper and aluminum soft metal plates.

CNC Wood Cutting CNC Woodworking Machine Description:

MDF Plywood Wood Cutting Machine is good at heavy-duty and complex 3d wood Cutting & Carving of wood panel, MDF, Polywood, etc. All the working areas and specifications can be customized according to your requests. Double platform MDF and plywood board cutting CNC Router machine is a multi-function automatic CNC nesting machine, which integrates cutting, chamfering, relief, ollowing, punching, slotting and other processes, while eeting the processing requirements of cabinet doors and cabinets.

CNC Wood Cutting CNC Woodworking Machine Features :

1. The lathe bed adopts strong welded steel tube to avoid distortion.

2. Y axis adopts double motors to keep stable moving.

3. Z axis adopts ball screw transmission to ensure high precision machining.

4. High accuracy rack rail travel method with high speed.

5. HIWIN square guide rail with high accuracy and heavy burthen.

6. Advanced international technology vacuum with double cavity.

7. Humanization design of lathe bed vacuum and easy working.

8. Intelligent protecting working fable.

9. The rotary device can do 3D woodworking on cylinders.

CNC Board Cutting Machine Parameter

| Model | iGC-4AP-1325 |

| Machine stroke | 1300*2500*200mm*2 stations |

| File format | G code |

| Workbench structure | Class A hard special vacuum adsorption table |

| Working voltage | 380V/50HZ |

| Bed | Heavy-duty stable bed, CNC gantry milling |

| Spindle | HQD 6KW air-cooled tool change spindles*2, 4.5KW tool change spindle*2 |

| Drive system | Server motor drive |

| Control system | LNC system + wireless handwheel |

| Rack | High precision helical rack |

| Guide rail | HIWIN square rail |

| Lead screw | TBI lead screw |

| Inverter | Fuling |

| Cabinet | Independent large computer cabinet |

| Dust collection system | Floating dust collection + central dust collection structure |

| Lubrication system | Electric motor oil pump microcomputer centralized lubrication control, regular and quantitative lubrication |

Advantage Of Cnc Mdf Cutting Machine:

Flawless Cutting Accuracy

With its computerized control, a CNC machine can produce multiple identical pieces. It can also produce one-off pieces that conform precisely to programming coordinates. This accuracy saves companies money by reducing waste pieces.

Excels at Intricate Design

CNC machines can execute intricate designs that manual machines can’t. CNC millers and routers routinely perform intricate millwork and cutouts for furniture. In years past, this work was by hand and reserved for premium products. Today, computer controlled machines make it widely available.

Fast Training Process

Due to the physical nature of the operator’s job, a manual woodworking machine can take years to master. Conversely, computer controlled machinery can be mastered in as little as weeks. A CNC machine operator controls its computer, oversees the production process, and performs light servicing – tasks that can be learned through training as easily as through experience.

Excellent Resale Value

As long as it is well maintained, industrial grade CNC machinery retains its value well. With woodworkers constantly on the lookout for quality used machinery, you shouldn’t have difficulty liquidating a machine when you need to upgrade to a new one.

Wood Board Cutting Machine Detail

| Seamless connection of four processes, multiple processes without manual tool changes |

| HQD air-cooled tool change spindles, 6KW*2+4.5KW *2; Cooperating with the cutting machine, it can only be driven to realize 0 second tool change and higher efficiency production |

| Double-station table, you can unload and cut at the same time, improve work efficiency |

| Feeding roller to increase the feeding speed |

| Class A hard double-layer vacuum adsorption table |

| High precision rack + HINWIN guide rail |

| Independent large computer cabinet LNC system + wireless handwheel |

CNC Wood Cutter Machine Sample

The most advanced, multi-function ATC Nesting CNC machine with drilling bank, perfect for professional scaled furniture manufacturers, designed by iGOLDENCNC for changing tools automatically while working, combined with a competitive set of configurations.

Hot applications include:

>Furniture industry: panel furniture, cabinets, sliding doors, soft bags, office furniture, wooden doors, whole house customization, etc.

>Wooden products: speakers, game cabinets, computer tables, sewing machine tables, musical instruments;

>Sheet metal processing: insulation parts, plasticized workpieces; pcb; inner body of motor vehicles, bowling track; carbonized mixtures such as anti-fold special board, epoxy resin, abs, pp, pe;

>Decoration industry: engraving and cutting of acrylic, PVC, MDF, plexiglass, plastic, and copper and aluminum soft metal plates.

content is empty!