iGS-B(Pro)

iGOLDENCNC

iGOLDEN-iGCL-iGS-B

| Availability: | |

|---|---|

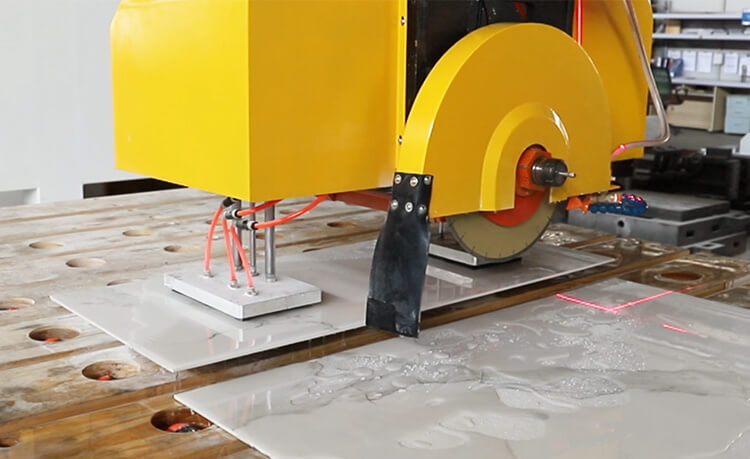

This is a 2023 newly designed 5 axis CNC bridge saw for stone cutting. It is added with a camera to automatically position plates. And the machine head can swing freely at 360°, which can cut and edge at any angle and shape for granite, marble, artificial stone, slate and other stone materials. So it is widely used in slate application industry, prefabricated building industry, home decoration industry, etc. Its maximum cutting length is 2800mm, maximum cutting widths is 1200mm, and maximum cutting thicknesses is 100mm. The worktable can tilt up to 80°and the spindle can rotate to 90° or 360°. It is the ideal machine for large and industrial stone professing factory.

Cutting, edging, chamfering, digging and other multi-functional intelligent operating system, simple and easy to learn; High quality motor, high precision, fast speed; Transverse, longitudinal, arc, circular, arbitrary Angle, shape cutting. The machine head can move and rotate freely. Besides cutting modeling, it can also open material for large plate, 45 degree chamfering, open basin hole, stove hole, and slash line cutting.

Suitable for quartzite, rock plate, artificial stone, granite, marble all kinds of large and small stone decoration engineering stone processing machinery. Save plate save time save worry save effort!It can implement different complex curved surface processing and combines the functions of cutting, drilling, milling, engraving into an oganic whole.

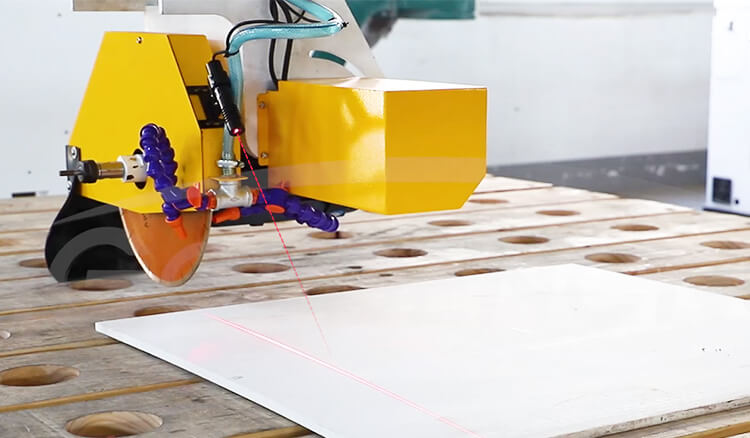

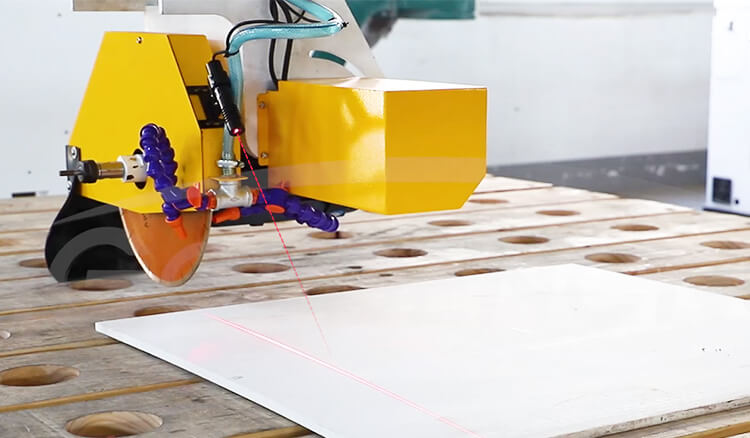

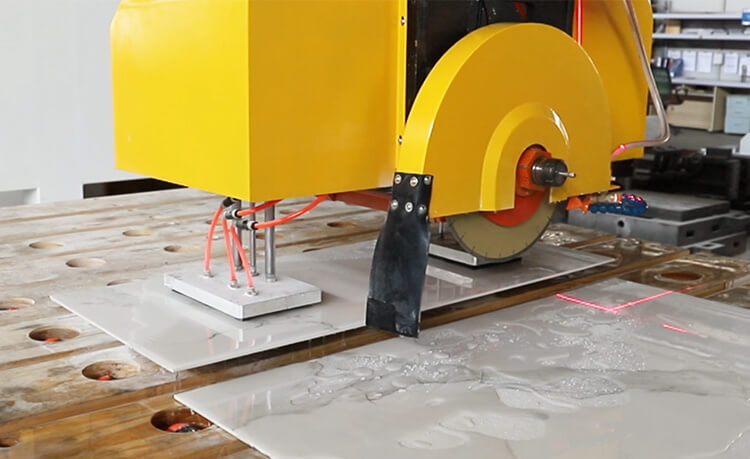

Infrared Localization,convenient to observe and adjust.

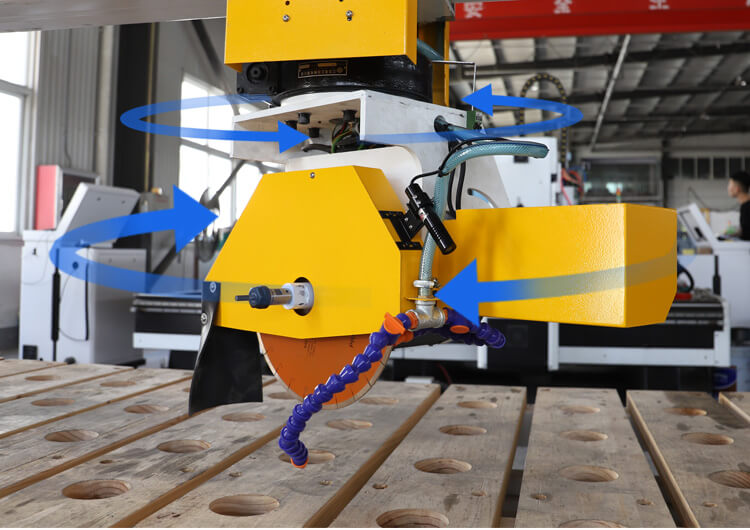

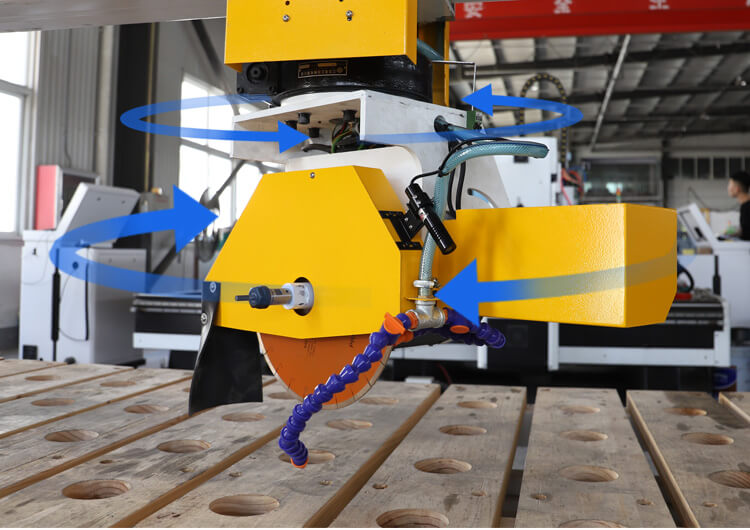

The machine head automatically flips ±360 degrees

The worktable can be turned left and right for easy loading and unloading

The machine head can move the plate, which is more convenient.

•Fully automatic touch screen Cutcam system

Striker plate Swage setting Camera function

(Option)3D Kitchen Bathroom Countertop Measuring Scanner with Laser Templator

Technical indicators | parameter |

Model | iGS-B-3320 |

Stroke of X axis | 3700mm |

Stroke of Y axis | 2000mm |

Z-axis stroke 1 | 255mm(Blade Diameter 400mm) |

Z-axis stroke 2 | 195mm(Length of milling cutter 40mm) |

A axis | 90° |

C axis | 360° |

Saw blade motor power | 7.5W / 15KW |

Blade Diameter | 400mm |

Input power | Single-phase AC 220V 50-60Hz 10A |

Dimensions | 5845mm(L)*3922mm(W)*3687(H)mm |

Total weight | 4300kg |

The high-efficiency stone bridge cutting machine designed by iGOLDENCNC adopts high-strength mechanical structure, which is very suitable for manufacturers who process special-shaped stone in batches. Imported linear guide rails are used to ensure accuracy and provide a set of competitive configurations.

Popular applications include:>Decoration industry: special-shaped lines and relief carvings of stone background walls;

>Stone countertops with digging basin holes and European borders: suitable for cabinet artificial stone, quartz stone, granite, marble countertops and sinks, kitchen countertops, bathroom countertops, special-shaped bar counters, stone coffee table countertops, basin hole cutting, back-arc water forming And polishing, etc.;

>45-degree side cutting, 90-degree right angle splicing and special-shaped processing;

>Drilling, grinding, trimming, carving, cutting, polishing and engraving of other special-shaped stones, ceramics, glass and ceramic stones.

It adopts 5 axis bridge cutting head, which is independently researched and developed and adopts the cast rotating bracket. This ensures good stability and flexibility during operation.

This bridge saw uses a high-precision RV reducer, ensuring better rotating precision of the cutting head.

It has built-in CAM software in the control system for the convenient of drawing designs and programming. Besides, it’s easy to learn the software to make designs.

The worktable can flip automatically up to 80 degrees, reducing human labor and facilitating the unloading process.

This bridge saw is ideal for cutting slabs of quartz, marble, granite and stone.

The bridge, slide rail and blade holder are made of strong cast iron, guaranteeing stability, durability, and low resonance.

This is a 2023 newly designed 5 axis CNC bridge saw for stone cutting. It is added with a camera to automatically position plates. And the machine head can swing freely at 360°, which can cut and edge at any angle and shape for granite, marble, artificial stone, slate and other stone materials. So it is widely used in slate application industry, prefabricated building industry, home decoration industry, etc. Its maximum cutting length is 2800mm, maximum cutting widths is 1200mm, and maximum cutting thicknesses is 100mm. The worktable can tilt up to 80°and the spindle can rotate to 90° or 360°. It is the ideal machine for large and industrial stone professing factory.

Cutting, edging, chamfering, digging and other multi-functional intelligent operating system, simple and easy to learn; High quality motor, high precision, fast speed; Transverse, longitudinal, arc, circular, arbitrary Angle, shape cutting. The machine head can move and rotate freely. Besides cutting modeling, it can also open material for large plate, 45 degree chamfering, open basin hole, stove hole, and slash line cutting.

Suitable for quartzite, rock plate, artificial stone, granite, marble all kinds of large and small stone decoration engineering stone processing machinery. Save plate save time save worry save effort!It can implement different complex curved surface processing and combines the functions of cutting, drilling, milling, engraving into an oganic whole.

Infrared Localization,convenient to observe and adjust.

The machine head automatically flips ±360 degrees

The worktable can be turned left and right for easy loading and unloading

The machine head can move the plate, which is more convenient.

•Fully automatic touch screen Cutcam system

Striker plate Swage setting Camera function

(Option)3D Kitchen Bathroom Countertop Measuring Scanner with Laser Templator

Technical indicators | parameter |

Model | iGS-B-3320 |

Stroke of X axis | 3700mm |

Stroke of Y axis | 2000mm |

Z-axis stroke 1 | 255mm(Blade Diameter 400mm) |

Z-axis stroke 2 | 195mm(Length of milling cutter 40mm) |

A axis | 90° |

C axis | 360° |

Saw blade motor power | 7.5W / 15KW |

Blade Diameter | 400mm |

Input power | Single-phase AC 220V 50-60Hz 10A |

Dimensions | 5845mm(L)*3922mm(W)*3687(H)mm |

Total weight | 4300kg |

The high-efficiency stone bridge cutting machine designed by iGOLDENCNC adopts high-strength mechanical structure, which is very suitable for manufacturers who process special-shaped stone in batches. Imported linear guide rails are used to ensure accuracy and provide a set of competitive configurations.

Popular applications include:>Decoration industry: special-shaped lines and relief carvings of stone background walls;

>Stone countertops with digging basin holes and European borders: suitable for cabinet artificial stone, quartz stone, granite, marble countertops and sinks, kitchen countertops, bathroom countertops, special-shaped bar counters, stone coffee table countertops, basin hole cutting, back-arc water forming And polishing, etc.;

>45-degree side cutting, 90-degree right angle splicing and special-shaped processing;

>Drilling, grinding, trimming, carving, cutting, polishing and engraving of other special-shaped stones, ceramics, glass and ceramic stones.

It adopts 5 axis bridge cutting head, which is independently researched and developed and adopts the cast rotating bracket. This ensures good stability and flexibility during operation.

This bridge saw uses a high-precision RV reducer, ensuring better rotating precision of the cutting head.

It has built-in CAM software in the control system for the convenient of drawing designs and programming. Besides, it’s easy to learn the software to make designs.

The worktable can flip automatically up to 80 degrees, reducing human labor and facilitating the unloading process.

This bridge saw is ideal for cutting slabs of quartz, marble, granite and stone.

The bridge, slide rail and blade holder are made of strong cast iron, guaranteeing stability, durability, and low resonance.