iGS-B

iGOLDEN

iGOLDEN-iGS-B

| Availability: | |

|---|---|

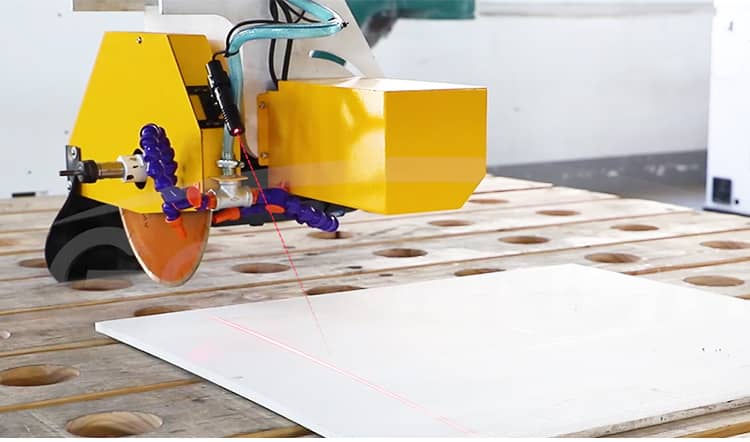

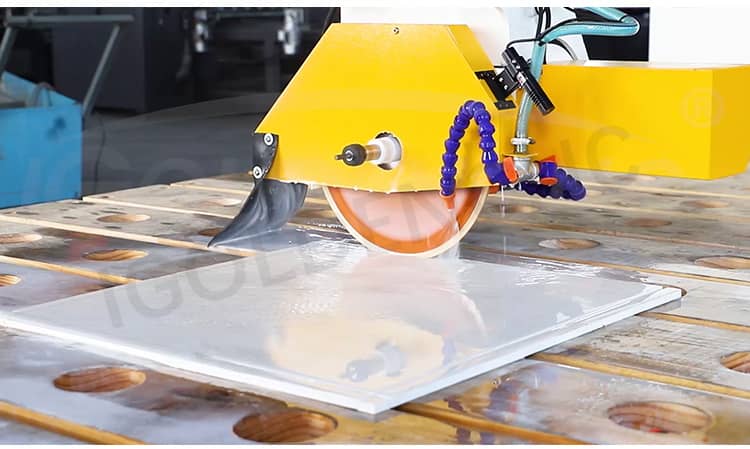

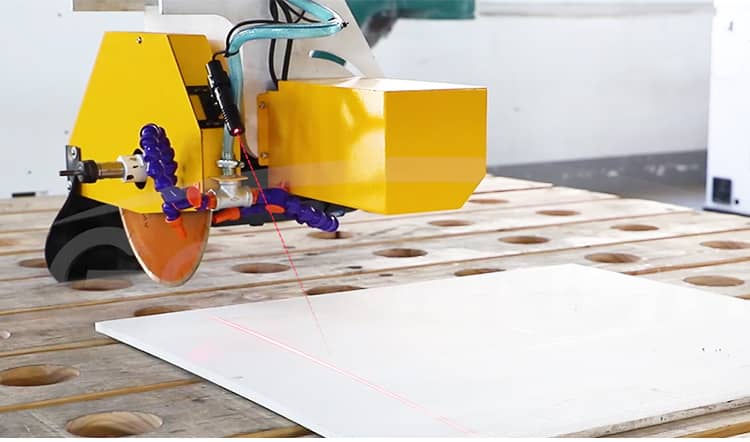

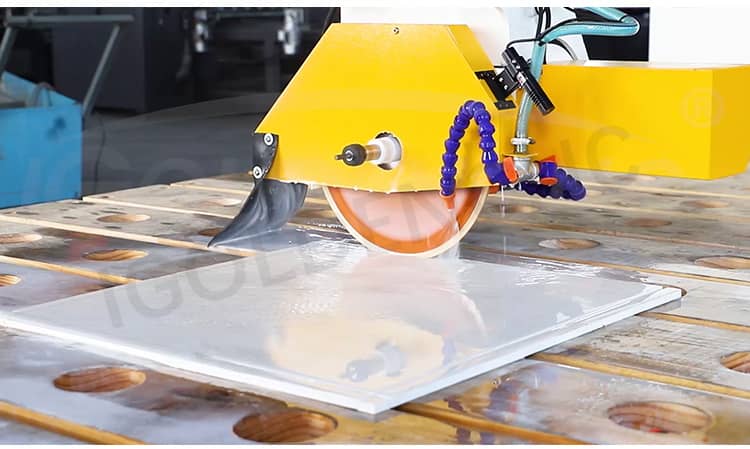

The Intelligent 4+1 bridge cutter is a fully functional processing equipment with a 360 degree rotation of the head. Saw blade with spindle can be cut, chamfering, digging and other multi-functional integration, intelligent operating system, simple and easy to learn; High quality motor, high precision, fast speed; Transverse, longitudinal, arc, circular, arbitrary Angle, shape cutting. The machine head can move and rotate freely. In addition to cutting modeling, it can also be used for large plate opening, 45 degree chamfering, opening basin hole, stove hole, oblique line cutting.

Suitable for quartzite, rock plate, artificial stone, granite, marble all kinds of large and small stone decoration engineering stone processing machinery. Save plate save time save worry save effort!

(Option)3D Kitchen Bathroom Countertop Measuring Scanner with Laser Templator

Looking to buy an affordable automatic bridge saw for cutting quartz, granite, marble, rock slab, ceramic tile to make custom kitchen countertops and personalized bathroom vanity tops?

A 4+1 Axis Bridge Cutting Machine is a type of advanced cutting machine used in industries such as stone processing, marble cutting, and granite fabrication. It is designed to cut and shape large blocks or slabs of stone or other hard materials with precision and efficiency.

Bridge Cutting Saw Parameter

Bridge Cutting Saw ParameterTechnical indicators | parameter |

Model | iGS-B |

Lathe bed | Heavy duty welded bed |

Gantry | Steel structure |

Table | Flip table |

Guide rail | HIWIN30 |

Rack | YYC 2M |

Motor power | 11KW / 15KW |

Saw blade diameter | 350mm/400mm/450mm |

Control system | Chengdu |

Voltage | 3 . 380V/220V 50-60Hz 10A |

Dimensions | 5651*4084*2673mm |

Function | Square, round, horse belly edge cutting, Taiwan basin cutting, laser positioning, knife, 45° oblique cutting, automatic copy feeding |

Opention | Dust-free measurement software |

Using automatic touch human-machine interface, intuitive operation, simple and convenient;

Main core control component USES the first-line brand, stable performance and long life;

Can spin 0 ° to 360 ° and 90 ° inclined processing, used in any direction and any Angle of the cutting;

Implementation heterosexual complex surface machining, cutting, milling, drilling and multi-function in one;

Increase other optional features, such as photo function layout, automatic measuring plate thickness, automatic pressure material, etc.

The high-efficiency stone bridge cutting machine designed by iGOLDENCNC adopts high-strength mechanical structure, which is very suitable for manufacturers who process special-shaped stone in batches. Imported linear guide rails are used to ensure accuracy and provide a set of competitive configurations. Popular applications include:

>Decoration industry: special-shaped lines and relief carvings of stone background walls;

>Stone countertops with digging basin holes and European borders: suitable for cabinet artificial stone, quartz stone, granite, marble countertops and sinks, kitchen countertops, bathroom countertops, special-shaped bar counters, stone coffee table countertops, basin hole cutting, back-arc water forming And polishing, etc.;

>45-degree side cutting, 90-degree right angle splicing and special-shaped processing;

>Drilling, grinding, trimming, carving, cutting, polishing and engraving of other special-shaped stones, ceramics, glass and ceramic stones.

The Intelligent 4+1 bridge cutter is a fully functional processing equipment with a 360 degree rotation of the head. Saw blade with spindle can be cut, chamfering, digging and other multi-functional integration, intelligent operating system, simple and easy to learn; High quality motor, high precision, fast speed; Transverse, longitudinal, arc, circular, arbitrary Angle, shape cutting. The machine head can move and rotate freely. In addition to cutting modeling, it can also be used for large plate opening, 45 degree chamfering, opening basin hole, stove hole, oblique line cutting.

Suitable for quartzite, rock plate, artificial stone, granite, marble all kinds of large and small stone decoration engineering stone processing machinery. Save plate save time save worry save effort!

(Option)3D Kitchen Bathroom Countertop Measuring Scanner with Laser Templator

Looking to buy an affordable automatic bridge saw for cutting quartz, granite, marble, rock slab, ceramic tile to make custom kitchen countertops and personalized bathroom vanity tops?

A 4+1 Axis Bridge Cutting Machine is a type of advanced cutting machine used in industries such as stone processing, marble cutting, and granite fabrication. It is designed to cut and shape large blocks or slabs of stone or other hard materials with precision and efficiency.

Bridge Cutting Saw Parameter

Bridge Cutting Saw ParameterTechnical indicators | parameter |

Model | iGS-B |

Lathe bed | Heavy duty welded bed |

Gantry | Steel structure |

Table | Flip table |

Guide rail | HIWIN30 |

Rack | YYC 2M |

Motor power | 11KW / 15KW |

Saw blade diameter | 350mm/400mm/450mm |

Control system | Chengdu |

Voltage | 3 . 380V/220V 50-60Hz 10A |

Dimensions | 5651*4084*2673mm |

Function | Square, round, horse belly edge cutting, Taiwan basin cutting, laser positioning, knife, 45° oblique cutting, automatic copy feeding |

Opention | Dust-free measurement software |

Using automatic touch human-machine interface, intuitive operation, simple and convenient;

Main core control component USES the first-line brand, stable performance and long life;

Can spin 0 ° to 360 ° and 90 ° inclined processing, used in any direction and any Angle of the cutting;

Implementation heterosexual complex surface machining, cutting, milling, drilling and multi-function in one;

Increase other optional features, such as photo function layout, automatic measuring plate thickness, automatic pressure material, etc.

The high-efficiency stone bridge cutting machine designed by iGOLDENCNC adopts high-strength mechanical structure, which is very suitable for manufacturers who process special-shaped stone in batches. Imported linear guide rails are used to ensure accuracy and provide a set of competitive configurations. Popular applications include:

>Decoration industry: special-shaped lines and relief carvings of stone background walls;

>Stone countertops with digging basin holes and European borders: suitable for cabinet artificial stone, quartz stone, granite, marble countertops and sinks, kitchen countertops, bathroom countertops, special-shaped bar counters, stone coffee table countertops, basin hole cutting, back-arc water forming And polishing, etc.;

>45-degree side cutting, 90-degree right angle splicing and special-shaped processing;

>Drilling, grinding, trimming, carving, cutting, polishing and engraving of other special-shaped stones, ceramics, glass and ceramic stones.