Views: 12 Author: Site Editor Publish Time: 2021-09-18 Origin: Site

Stone CNC Machine is a high precision equipment for lettering words or make drawings on marble granite and other stone materials. Just like a engine on the car, Spindle is the most important part for stone engraving machine. A good quality stone engraving machine requires a high efficiency, stable and reliable spindle.

Nowadays, stone materials play a more and more important role on our life, the stone engraving business is increasing day by day. So we can see Stone engraving machine will getting more and more automation in the coming future. We have a advanced 3d statue engraving machine, it’s more suitable for carving a 3d stone materials. We using high quality spare parts on this engraving machine, we use good quality parts like bearings, motors, pump, press parts, and other electric parts on the machine. Stone engraving machine is widely used in stone lettering, house decoration, tombstone industry etc. The table size of Stone CNC Machine is normally fixed with 3200*2000mm while the table size of stone engraving can be customized. The table size could be 1300*1800mm or 1800*2500mm, 3000*2000mm or other size.

1. The machine head can swing 360 degrees freely, and the plate can be cut at any angle and shape

2. It can be used for cutting large plate, 45 degree chamfering, countertop sink hole,oblique line cutting and simple carving.

3. The platform is turned over at 85 degrees to facilitate loading and unloading.

4. The operation is simple and the control system can input data.

5. Equipped with milling tool, it can polish cutting surface. And do 3D profiling. (Optional)

6. Equipped with simulation software for processing scheme checking.

1. The three-axis of stone engraving machine adopts high-precision square guide rail to effectively ensure the accuracy and stability of mechanical operation.

2. The thick wall square steel of the bed adopts seamless welding to eliminate the residual stress. The bearing force can reach more than three tons, which is firm and durable without deformation.

3. The stone engraving machine adopts dust-proof structure, which effectively protects the guide rail and lead screw from dust or moisture, and improves the service life of the machine tool.

4. High power 5.5kw water-cooled main shaft, with imported bearing configuration, low noise and high power of main shaft.

5. The system adopts Weihong control system, stable operation and convenient operation.

6. The table top is equipped with thickened stainless steel sink, two-way cooling tool, improving the service life of the tool.

Stone CNC Machine echnical Data

| Workpiece Size | mm | 350*1000*6 |

| Z Axis Working Height | mm | 600 |

| Positioning Accuracy | mm | 0.05 |

| Re-positioning Accuracy | mm | 0.02 |

| Body Structure | Welding Body | |

| X, Y, Z Axis Structure | Linear Guide Rail, Ball Screw | |

| Max. Running Speed | mm/min | 30000 |

| Max. Working Speed | mm/min | 15000 |

| Spindle | kw | 5.5kw Water-cooling Spindle*6(6-12 Spindle Optioned) |

| Spindle RPM | rpm/min | 24000 |

| Working Voltage | V/Hz | AC 380V±10%/50-60Hz |

| Machine Weight | kg | 6300kg |

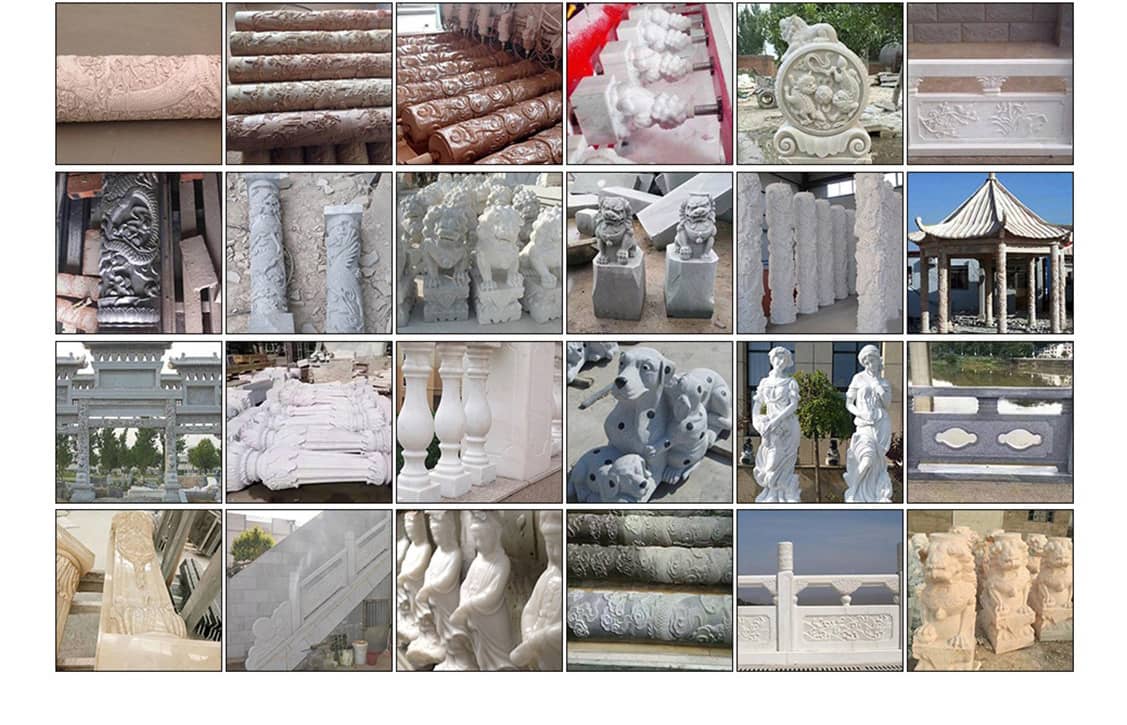

Stone CNC Machine Application:

It can process many materials, like Artificial stone, Marble, Granite, Ceramic Tile, milestone,Terrazzo,Limestone,Sandstone, Travertine,

Quartzite, Slate, grindstone, Jade, Wood, Plastics, etc.

We are a company integrating manufacturing and sales of CNC routers, laser engraving machines, laser cutting machines, plasma cutting machines, cutting plotters, etc. The main configuration all adopt top parts imported from Italy, Japan, Germany, etc.We adopt international advanced producing technologies to improve our products. Our products are widely used in advertising, woodworking, artworks, model, electric, CAD/CAM industry models, clothing, package printing, marking, laser sealing and so on.

Our company adheres to the Market-Oriented business principles, and implements the business philosophy of "Quality First and Customer First". We have set up more than 20 sale and service departments around China which can offer our customers the services of design, fixing, training, maintenance and so on. Besides sale in China, our products exports around the world including the Middle East, Africa, Europe and the USA.