Views: 11 Author: Site Editor Publish Time: 2022-07-19 Origin: Site

CNC plasma cutting machine is the oldest form of cutting. Its history can be traced back to the 1950s and is an alternative to flame cutting. Plasma cutting is performed by jetting superheated ionized gas (ie plasma) from a nozzle toward the workpiece at a high speed. Then an arc is formed in the gas. The arc ionizes part of the gas, thereby forming a conductive channel for the plasma in the process.

When the electricity from the torch travels down the plasma, it generates enough heat to melt through the workpiece. The plasma and compressed gas blow away the hot molten metal, causing the workpiece to separate.

plasma cnc cutting machine adopts light-weight structural design, the structure has good rigidity, light weight and small motion inertia. plasma cutting machines are widely used in automobiles, locomotives, pressure vessels, chemical machinery, nuclear industry, general machinery, engineering machinery, steel structures and other industries!

Performance Characteristics

u Cutting speed is up to 18 meters per minute with an accuracy of ±0.3mm.

u The structure of the boring machine adopts a combination of rivet welding and assembly to prevent deformation of the body itself.

u The cutting port is small, tidy, and has no slag phenomenon, avoiding secondary dressing processing.

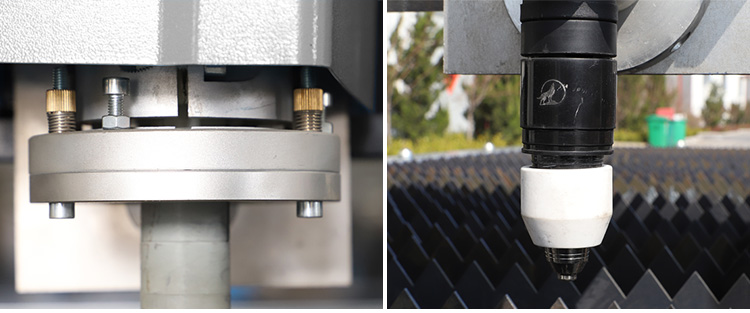

u The CNC system has high configuration, automatic arc ignition and stable performance. The success rate of arc ignition is more than 99%.

u Plasma power supply and cutting gun are equipped with domestic famous brands and manufacturers of many foreign patented technologies.

u It can be combined with other advertising equipment (blister machine, metal slotting machine, metal folding machine) to form metal craft font production and processing line.

u precision.Supports standard G code path files generated by software such as ARTCUT, CAXA, ARTCAM, TYPE3, etc., and supports DXF format files generated by other software. The control system uses U disk exchange processing

Sample & Application

Application Materials: Stainless steel, mild steel, brass, copper, aluminum alloy, sheet metal, spring steel, gold, silver, etc.

Application Industry: Sheet metal, kitchenware, components, decorations industry.

Increased Productivity

CNC plasma cutting systems come with automatic torch height control and sophisticated CAD and CAM cutting software which also enhances productivity so that you can make more cuts in a day, with less waste. Our systems are capable of achieving pristine cuts with less heat damage so that each piece you cut is exactly the dimensions and requirements that you need. This ensures happy customers on your end, which often turn into repeat customers. Because you will be producing more cuts that are high in quality and retaining happy repeat customers, investing in a cnc plasma cutting machine is a smart choice that will more than pay for itself in a short matter of time.