Views: 4 Author: Site Editor Publish Time: 2022-06-28 Origin: Site

What is Plasma cutting machines?

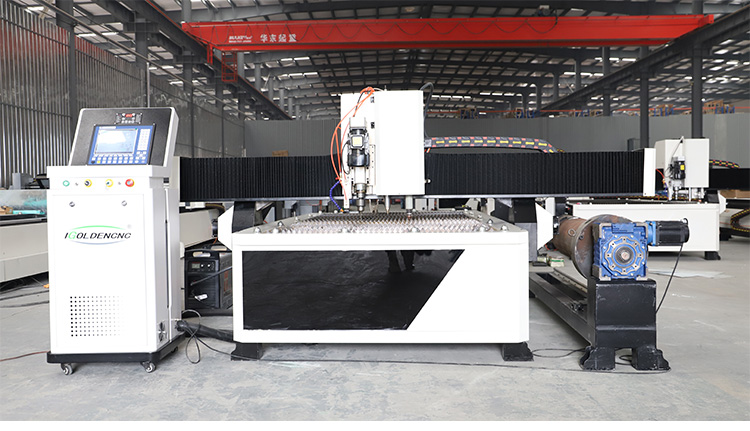

CNC plasma metal cutting machine is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma.

.

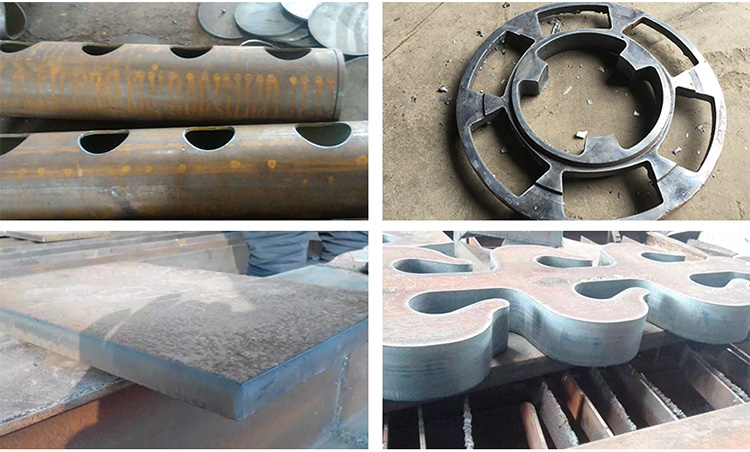

plasma table cutter applications are also more extensive, such as the application of sapphire, glass, ceramic precision cutting; FPC, PCB board precision cutting and drilling, all kinds of metal and non-metallic thin plate precision cutting and so on.Plasma Cutting Machine

Very high cut quality and straight cutting edges (various plasma cutting quality levels)

High cutting speed (eventually higher than laser)

Cutting gases can be adapted to the materials to-be-cut: oxygen for mild steel; nitrogen, hydrogen or argon in case of CrNi

Medium heat diffusion into the to-be-cut material (lower than in case of oxy-fuel)

Reduced hardness increase on cutting edges

Cut objects with metallurgically optimal surfaces (oxidized or nitrogenized)

How to Use Plasma Cutting Machine Effectively?

So far, the previous section covered the working of plasma cutters. Now, let’s focus on how to make the best use of the tool.

CNC plasma machine uses a plasma cutter to cut thin to thick metals along a multi-axis grid. The CNC method provides an advantage over handheld plasma cutting tools due to the cut being programmed and controlled by a computer instead of human motion. CNC plasma is where high speed and precision meet low cost – among a vast array of additional benefits.

Plasma cutting is a high-tech cutting method that uses an ionised, focused jet of gas to slice through thin sheet metal. An internal, high-voltage electrode in the cutter rapidly heats a compound gas mixture to over 20,000 centigrade when switched on. Shielding gas is used as a propellant and barrier to focus and move the induced plasma from the ionisation chamber. The ionised, superheated, concentrated beam of plasma then melts and blasts any metal it touches. A clean, sealed cut is made each time.

Field Uses: There are a variety of plasma cutters available in a wide range from inexpensive to high-end branded models. Most of them are performance-driven, and can exactly match your need. For field use, you will need a machine with approximately fifteen to twenty leads. So, you can fulfil your needs and still able to save on air and electricity.

Shop Uses: You can easily find plasma cutters in shops. They can be used with computer numerical control (CNC) machines, and you’ll be amazed by the results. You can transform a raw sheet of steel into some incredibly designed workpieces. With plasma cutters, you can produce accurate cuts repeatedly; manually, it can be mundane and prone to errors.

Other Uses: Other usages of this tool vary based on different projects. This may include art installations, apartment renovations, and beyond. Additionally, plasma cutter also makes your repair task easy by cutting a small piece of metal without taking you to the shop.

To get the expected quality and precise cut, it is important to choose the right plasma cutting machine from an industry-leading supplier like IGOLDENCNC. Browse the high quality Plasma Cutting Machine PL320, Cut up to 5/16″ Mild Steel. The company is a leading provider of sheet metal fabrication tools and equipment.