iGP-4A

iGOLDENCNC

iGOLDENCNC iGP-4A

| Availability: | |

|---|---|

The cnc plasma cutter table is one of the most fine-tuned, broadly used, efficient and versatile tools for cutting even heavyweight and thick materials quite quickly. When it comes to cutting materials for various types of manufacturing and construction applications

Nothing gets the job done quite like a CNC plasma cutting table. Plasma cutting machines are computer automated, which allows for an incredibly high level accuracy for a precise cut every single time. They are successfully used in the metal cutting processes in the manufacturing, agricultural, engineering and construction industries.

1, the maximum cutting speed can reach 18m/min, precision control within ±0.3mm.

2. The machine structure adopts rivet welding combination to avoid machine deformation.

3, cutting less and neat, no cutting slag, no post-treatment.

4, suitable for low carbon steel plate, aluminum plate, galvanized plate, titanium plate, etc.

5, support ARTCUT, CAXA, ARTCAM, Type3 software generated g-code files or other software generated DXF format files. The control system adopts U disk exchange processing.

6, high configuration CNC system, stable performance. The success rate of automatic arc initiation can reach 99%.

7. Laser module positioning. High positioning accuracy, humanized design.

8. Plasma power supply and cutting torch adopt Chinese famous brand products and obtain national patent

9、Overall stepper motor with high precision rack and pinion, to ensure the cnc plasma Machine has small noise,smooth, precise coordinates of the mobile performance.

It is a type of automatic cutting machine with custom welding table top, which can be well adapted to cut metal projects with different sizes. The CNC controller will make it with a high degree of manufacturing flexibility, high accuracy, stable quality, high productivity, easy to improve working conditions, and are conducive to modernization of production management. Such a tool is a combination of a cutter and controller, which can give play to the greater advantages of gas cutting.

In order to realize automatic machining, it must be capable of continuous feeding and automatic feeding, and the torch must be able to move separately or in combination in the horizontal and vertical directions to form the required curve. The various functional parts of the machine must be able to closely cooperate and coordinate to achieve precise continuous cutting. At the same time, various technical parameters can be flexibly adjusted and optimized to meet the cutting requirements of different metals.

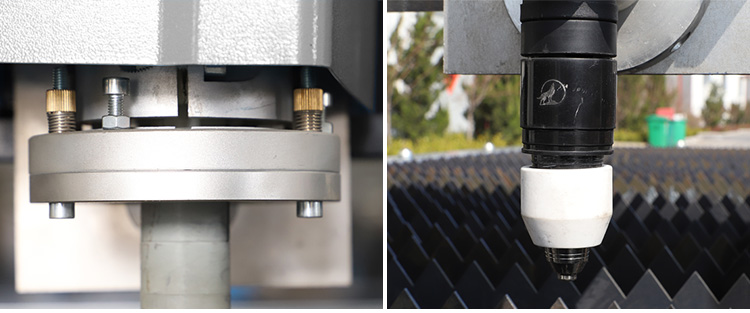

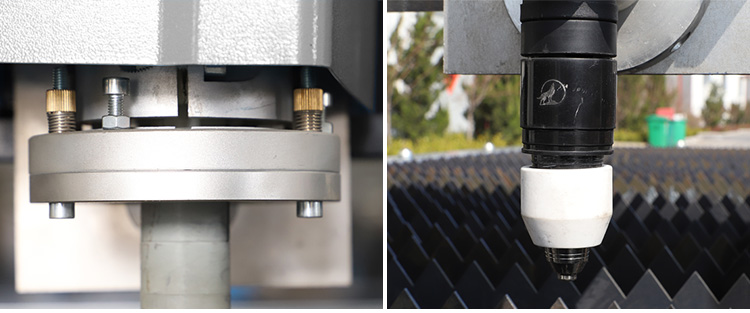

There are three essential components of a cheap cnc plasma cutter: the power supply, the plasma arc starting console, and the plasma torch. The power supply of a plasma cutter converts the AC voltage into a constant DC voltage which ranges from 200 to 400 VDC. The DC voltage has to be constant to maintain the plasma arc during the cutting process. The power supply system also controls the current output based on the amount it needs to cut through certain types and thickness of materials. The thicker or more rigid the workpiece is, the greater output of electric current is required.

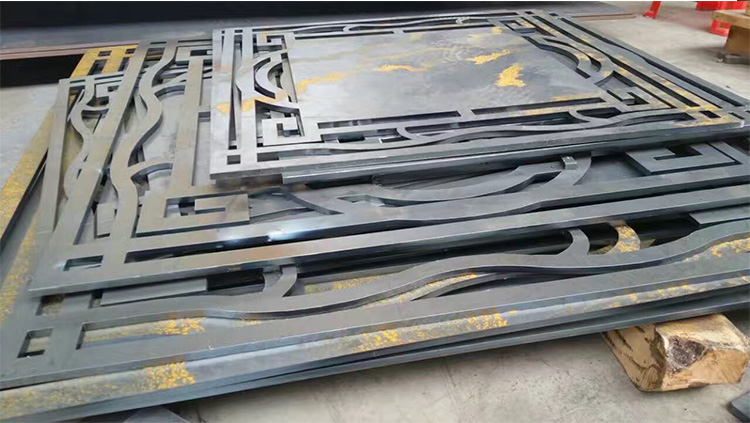

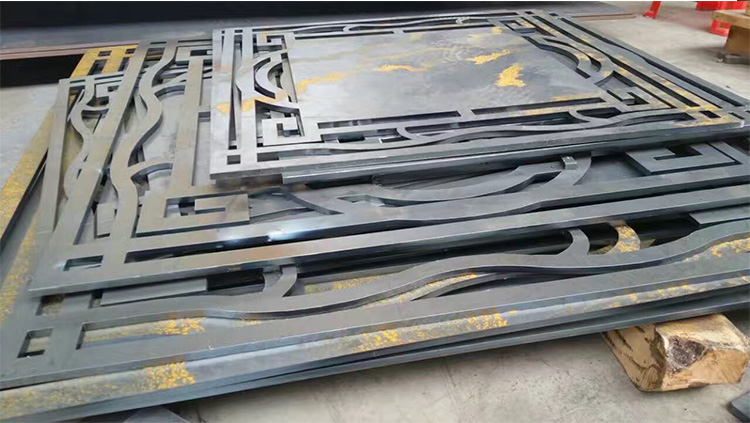

Sample & Application

Advertising industry: Advertising signs, logo making, decorative products, production of advertising and a variety of metal materials.

Mold Industry: Engraving metal molds made of copper, aluminum, iron and so on.

Metal industry: For steel, Carbon Steel, Stainless steel, alloy steel, spring steel, copper plate, aluminium plate, gold, silver, Titanium and other metal plate and tube.

iGOLDEN CNC plasma cutting tables are configured with a motion controller that sets the bar for acceleration and deceleration rates, a plasma cutter that increases cut speeds and outlasts competing consumable life cycles by nearly 3x, and a linear motion system that hits gantry and torch travel speeds of up to 500 ipm. All of these features accelerate cost savings for our customers. The faster cut speeds and higher acceleration and deceleration rates reduce job cycle times and increase the amount of metal parts your shop is able to sell.

The cnc plasma cutter table is one of the most fine-tuned, broadly used, efficient and versatile tools for cutting even heavyweight and thick materials quite quickly. When it comes to cutting materials for various types of manufacturing and construction applications

Nothing gets the job done quite like a CNC plasma cutting table. Plasma cutting machines are computer automated, which allows for an incredibly high level accuracy for a precise cut every single time. They are successfully used in the metal cutting processes in the manufacturing, agricultural, engineering and construction industries.

1, the maximum cutting speed can reach 18m/min, precision control within ±0.3mm.

2. The machine structure adopts rivet welding combination to avoid machine deformation.

3, cutting less and neat, no cutting slag, no post-treatment.

4, suitable for low carbon steel plate, aluminum plate, galvanized plate, titanium plate, etc.

5, support ARTCUT, CAXA, ARTCAM, Type3 software generated g-code files or other software generated DXF format files. The control system adopts U disk exchange processing.

6, high configuration CNC system, stable performance. The success rate of automatic arc initiation can reach 99%.

7. Laser module positioning. High positioning accuracy, humanized design.

8. Plasma power supply and cutting torch adopt Chinese famous brand products and obtain national patent

9、Overall stepper motor with high precision rack and pinion, to ensure the cnc plasma Machine has small noise,smooth, precise coordinates of the mobile performance.

It is a type of automatic cutting machine with custom welding table top, which can be well adapted to cut metal projects with different sizes. The CNC controller will make it with a high degree of manufacturing flexibility, high accuracy, stable quality, high productivity, easy to improve working conditions, and are conducive to modernization of production management. Such a tool is a combination of a cutter and controller, which can give play to the greater advantages of gas cutting.

In order to realize automatic machining, it must be capable of continuous feeding and automatic feeding, and the torch must be able to move separately or in combination in the horizontal and vertical directions to form the required curve. The various functional parts of the machine must be able to closely cooperate and coordinate to achieve precise continuous cutting. At the same time, various technical parameters can be flexibly adjusted and optimized to meet the cutting requirements of different metals.

There are three essential components of a cheap cnc plasma cutter: the power supply, the plasma arc starting console, and the plasma torch. The power supply of a plasma cutter converts the AC voltage into a constant DC voltage which ranges from 200 to 400 VDC. The DC voltage has to be constant to maintain the plasma arc during the cutting process. The power supply system also controls the current output based on the amount it needs to cut through certain types and thickness of materials. The thicker or more rigid the workpiece is, the greater output of electric current is required.

Sample & Application

Advertising industry: Advertising signs, logo making, decorative products, production of advertising and a variety of metal materials.

Mold Industry: Engraving metal molds made of copper, aluminum, iron and so on.

Metal industry: For steel, Carbon Steel, Stainless steel, alloy steel, spring steel, copper plate, aluminium plate, gold, silver, Titanium and other metal plate and tube.

iGOLDEN CNC plasma cutting tables are configured with a motion controller that sets the bar for acceleration and deceleration rates, a plasma cutter that increases cut speeds and outlasts competing consumable life cycles by nearly 3x, and a linear motion system that hits gantry and torch travel speeds of up to 500 ipm. All of these features accelerate cost savings for our customers. The faster cut speeds and higher acceleration and deceleration rates reduce job cycle times and increase the amount of metal parts your shop is able to sell.