Views: 29 Author: igoldenCNC Publish Time: 2024-12-11 Origin: igoldenCNC

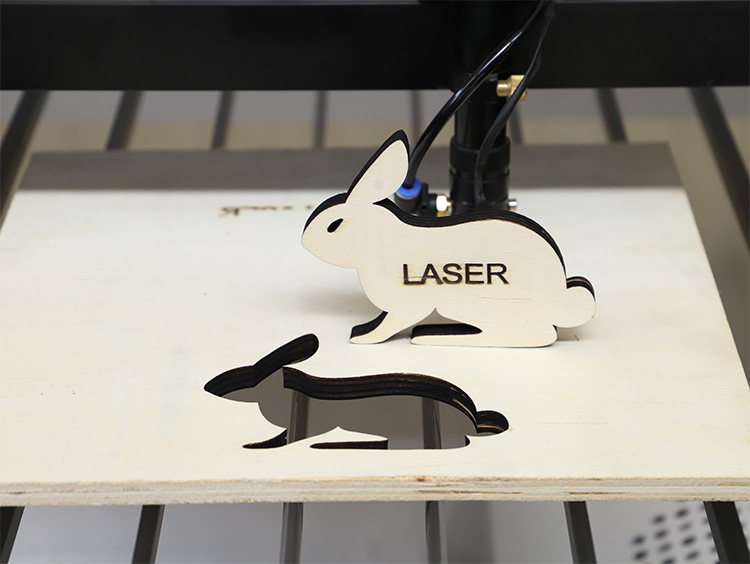

In the world of modern manufacturing, precision, speed, and efficiency are crucial. Whether you’re working with metals, plastics, wood, or even fabrics, achieving accurate cuts and intricate designs is a key part of producing high-quality products. CNC laser cutting machine has emerged as one of the most powerful tools for achieving these goals. These advanced machines use focused laser beams to cut through various materials with exceptional precision, making them an essential tool in industries ranging from automotive and aerospace to fashion design and electronics.

Let's explore together what CNC laser cutting machines are, how they work, their applications, and why they are the ideal choice for high-quality and detailed cutting. We’ll also highlight some key factors to consider when investing in a CNC laser cutting machine to ensure you get the best value for your business.

Computer Numerical Control laser cutting machine is a type of automated equipment that uses a high-powered laser to cut or engrave materials with precision. The CNC system allows the machine to follow complex patterns and designs by reading instructions from a CAD file. The operator focuses the laser on the material surface, melting, burning, or vaporizing the material to create clean, precise cuts.

Laser Source: The source generates the laser beam. It can be either CO2 (for cutting non-metals) or fiber (for cutting metals).

CNC Controller: This is the brain of the system, which interprets the design and controls the movement of the laser head.

Laser Head: The laser beam is focused through this component and directed at the material to perform the cutting.

Motion System: The machine uses motor-driven axes to move the laser head along the material, ensuring precise movement according to the design.

Focusing Lens: It focuses the laser beam onto the material for optimal cutting precision.

CNC laser cutting machines operate by following precise instructions that come from a digital file created through CAD software. Here’s a step-by-step breakdown of the process.Here’s a generalized explanation of the CNC laser cutting process:

The designer creates a design using CAD (Computer-Aided Design) software.

The designer converts the CAD design into a CNC program using CAM (Computer-Aided Manufacturing) software.

The operator prepares the chosen material and places it on the CNC machine’s work surface.

The operator sets up the machine according to the specific cutting requirements.

The CNC machine guides the laser beam along the programmed path, cutting through the material under the operator's supervision.

During the laser cutting process, the operator cools the material to prevent overheating and aid solidification.

Once the cutting is finished, the inspector checks the parts for quality, and if necessary, the technician may perform post-processing steps.

High Precision and Detail is one of the standout benefits of CNC laser cutting. The highly focused laser beam enables extremely precise cuts, allowing for intricate and detailed designs that traditional cutting methods cannot achieve. Whether you're working on delicate patterns or complex designs, CNC laser cutting ensures high accuracy with minimal deviation.

Another significant advantage is minimal material waste. Since the laser beam is incredibly thin and focused, CNC laser cutting makes precise cuts with minimal scrap. This efficient use of material not only reduces waste but also helps businesses save on material costs, making it a highly cost-effective solution.

Versatility is another key benefit of CNC laser cutting. These machines can cut through a wide variety of materials, including metals, plastics, wood, acrylics, and fabrics. Regardless of the material's thickness or delicacy, the laser can handle it with ease, making it suitable for a wide range of industries and applications.

Additionally, CNC laser cutting is known for its speed and efficiency. Automated operations significantly reduce production times compared to manual methods, helping businesses meet tight deadlines and high production demands. The automation also reduces the need for human intervention, cutting down on errors and increasing overall productivity.

Finally, clean cuts and high-quality finishes are guaranteed with CNC laser cutting. The laser's precision creates sharp, clean edges, often eliminating the need for secondary processing like sanding or finishing. This results in a higher-quality final product and reduces post-production labor costs, contributing to a more efficient production process.

CNC laser cutting machines are used in a wide range of industries. Some of the most common applications include:

Metal Cutting: CNC laser cutters are widely used in industries like automotive, aerospace, and manufacturing for cutting metals such as steel, aluminum, and titanium. The high precision of laser cutting makes it ideal for producing parts with intricate designs, tight tolerances, and complex geometries.

Signage and Graphics: CNC laser cutters are often used in the creation of signs, logos, and other graphic elements. They can cut various materials, including metals, acrylics, and wood, to create detailed signage for both indoor and outdoor use.

Prototyping and Product Development: In product design and prototyping, CNC laser cutters are invaluable tools. Designers can quickly produce prototypes with intricate details to test out concepts before moving into full-scale production.

Textile and Apparel Industry: CNC laser cutting machines are also used in the fashion and textile industries to cut fabrics with precision. Laser cutting offers a smooth, clean edge without the fraying or distortion that can occur with traditional cutting methods.

Art and Sculpture: Artists use CNC laser cutters to create precise sculptures, art installations, and intricate patterns. Laser cutting is particularly valuable for creating delicate pieces and intricate details in artwork.

Packaging Industry: In the packaging industry, CNC laser cutting is used to create custom packaging solutions, including foam inserts, cardboard packaging, and other protective materials. The precision of laser cutting ensures that products fit perfectly into their packaging.

When investing in a CNC laser cutting machine, it’s important to consider several factors to ensure that you choose the right machine for your business needs.

Material Compatibility: Consider the types of materials you will be cutting and ensure that the CNC laser router you choose can handle them. Some machines are designed specifically for metal cutting, while others are suited for cutting a broader range of materials, such as wood, plastic, or fabric.

Laser Power: The laser power determines the thickness and type of materials that the CNC laser cutter can handle. For instance, higher-powered lasers are needed for cutting thicker metals, while lower-powered lasers are sufficient for thinner materials or non-metallic materials.

Cutting Area: The size of the cutting area determines the maximum size of the material you can work with. Larger cutting areas are essential if you plan on working with larger sheets of material or producing bigger parts.

Software and Compatibility: The software that controls the CNC laser cutter is crucial. Ensure that the software is compatible with your design files (such as CAD files) and that it’s easy to use. Many CNC laser cutters are compatible with popular design software like AutoCAD, Adobe Illustrator, and CorelDRAW.

Budget: CNC laser cutting machines come in a wide range of prices. While higher-end machines offer more features, consider your budget and choose a machine that meets your requirements without exceeding your financial limits.

CNC laser cutting machines are a game-changer for industries that require high-precision cuts and intricate designs. From metal cutting in automotive and aerospace industries to creating detailed art and prototypes, these machines provide the accuracy, speed, and versatility needed to stay competitive in today’s market. Whether you’re cutting metals, plastics, wood, or fabrics, a CNC laser cutting machine offers a cost-effective and efficient solution for producing high-quality products with clean, precise edges.

When selecting a CNC laser cutter, consider factors like material compatibility, laser power, and cutting area to find the best machine for your business needs. By integrating CNC laser cutting technology into your production process, you can enhance your ability to create complex designs, reduce waste, and improve overall efficiency.

1. Can CNC laser cutting machines cut through thick metals?

Yes, CNC laser cutters with higher laser power are capable of cutting through thick metals, such as stainless steel and aluminum, making them ideal for industries like automotive and aerospace.

2. How do CNC laser cutters compare to traditional cutting methods?

CNC laser cutters offer several advantages over traditional methods, including greater precision, faster cutting speeds, cleaner cuts, and less material waste.

3. What materials can be cut with a CNC laser cutter?

CNC laser cutters can cut a wide range of materials, including metals, wood, acrylic, plastics, textiles, and foam.

4. How long does it take to set up a CNC laser cutting machine?

Setup time depends on the complexity of the design and the material being used. However, CNC laser cutters are relatively easy to set up once the design is uploaded and the material is placed.

5. Are CNC laser cutting machines suitable for prototyping?

Yes, designers widely use CNC laser cutting machines for prototyping. The machines’ precision, ability to handle complex designs, and speed enable designers to quickly test and iterate prototypes before full-scale production.